Bangor's C&L Air Services doubles staff and revenue in 18 months

Photo/Jason P. Smith

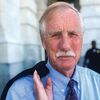

Chris Kilgour, CEO of C&L Air Services, in his 40,000-square-foot aviation facility in Bangor

Photo/Jason P. Smith

Chris Kilgour, CEO of C&L Air Services, in his 40,000-square-foot aviation facility in Bangor

From Brisbane, Australia, to Bangor, Maine, from England to Mongolia, C&L Air Services is making a name for itself, carving out a niche in a highly competitive aviation industry.

In the 18 months since it took over the Telford Aviation Services airplane maintenance facility at Bangor International Airport — a facility that was set to close — C&L has doubled its work force, growing to 60 employees in Bangor and another 25 worldwide. Sales have increased to an anticipated $30 million this year, up from about $18 million a few years ago, says Chris Kilgour, founder and CEO of Brisbane-based C&L Aerospace, the parent company of the air services operation.

The company has invested in new equipment and new operations, including a $50,000 machine shop and $200,000 in engine shop tools. C&L now even produces equipment, for its own use and for sale to other companies, and Kilgour is expanding the company's involvement in jet engine work.

It's a complex operation that developed out of simpler beginnings. Kilgour began honing his aviation entrepreneurial skills when he was 19, by establishing a company in Australia that took aerial photographs of properties and sold them to farmers.

The recent changes and improvements in Bangor are calculated to make C&L more efficient and versatile, more nimble and competitive here and abroad.

"We've been building our capabilities in certain areas and specializing, and people come to rely on us," says Kilgour, now 43, who moved his family to Hampden from Brisbane after buying Telford in May 2010. "We are harvesting the fruits of our labors."

Essential connections

C&L Air Services provides maintenance and parts for smaller, turbo prop planes and, to a lesser degree, jet aircraft.

"These aircraft are critically important for smaller cities that must maintain their links to the national and international air transport system," says Bob Ziegelaar, an economic development consultant who has extensive experience in the aviation industry, particularly as it pertains to Bangor. "From that perspective, I can only see C&L's market segment getting bigger."

When Ziegelaar was the director of Bangor International Airport, from 1991 to 2001, he saw Telford Aviation Services expand at the airport. After retiring from the airport, he joined Telford as its president.

It was Ziegelaar who facilitated C&L's purchase of the Telford Group's Bangor operation, which was to be closed by ACC Holdings, the Wisconsin-based cargo company that bought Telford in 2009.

Bangor's operation was a good fit for Kilgour's growing business. By the time Telford Aviation Services went up for sale, Kilgour had established C&L Aerospace in Australia, England and the United States. The business, which he started in 1994, emphasized selling airplane parts to the Australian military.

He had warehouses in California, London and Brisbane. The company also has maintained a limited inventory operation in Mongolia, where one of its customers flies.

While C&L Aerospace dealt with parts, Telford's emphasis was on aircraft maintenance, including heavy checks, deep-level overhauling that required stripping a plane down to the bare bones, and more routine maintenance.

Before it acquired Telford, C&L would buy planes and have other companies take them apart. C&L would then get the parts and send them out to be certified as reusable. The cumbersome process cost C&L more time and money than it would by doing the whole job itself.

Together, the maintenance and parts operations meshed so well that after he bought Telford's facility in Bangor, Kilgour moved his warehouse from California to Bangor, bringing jobs and prospects for more growth.

"Now we try to bring everything here to be done," Kilgour says.

That cuts costs. For example, the company now can keep a whole plane and take additional parts off it if needed, rather than have another company dismantle it and send C&L just the parts.

Putting parts and maintenance under one roof also allows greater oversight of quality control, Kilgour says. That's important in an industry that requires high precision and quick turnarounds.

The company's dual role also increases its exposure. Beyond having parts sales personnel cover the globe, the company regularly sends aircraft technicians all over the world, including to the Bahamas, Thailand and Kenya.

Although C&L can work on a variety of planes, it specializes in — and has become the major player in — maintenance of Saab 340s, twin turbo-prop planes that carry 30 to 36 passengers. It has contracts to maintain 17 of the Saab planes that businesses use for leases, and attracts international customers to Bangor to have their planes serviced.

"We sort of have the whole market covered in the Saab 340," Kilgour says during a tour of his 40,000-square-foot facility at the south end of the runway at Bangor International Airport. "We can offer the customer the whole service and we can save customers money."

C&L and Telford Aviation Services have had a strong relationship with Saab. The Swedish company retains a permanent lease office at C&L's facility in Bangor, where a Swedish flag stands in the reception area.

Ziegelaar, who now heads MainXPO, a business development consulting firm, says C&L expanded on what Telford began.

"C&L has taken the relationship with Saab to a new level and has also established relationships with other manufacturers in the aircraft and aircraft engine segments of the business," he says.

Last year, C&L and Finland-based Alandia Air announced that they were purchasing all 20 of General Electric Engine Services' CT7 leased engines. Kilgour estimates that, initially, $20 million worth of parts will roll through his doors. C&L will test and repair the parts — when they can be repaired — then send them out to be certified and sell them.

That could lead to other business.

"It may be the first step in something that may get bigger," Kilgour says, such as increased consignment sales and expansion into other kinds of engines.

Already, this strategy is strengthening the company.

"We are the biggest in the world for spare parts on the CT7 outside of GE, who makes it," he says. "But we even sell parts to GE."

An inward focus

To succeed, Kilgour is making his company rethink the way it does business.

While companies look to outsource, as Kilgour once did extensively, C&L is expanding what it does in-house.

In its new machine shop, it can fabricate items needed to repair plane parts. The company has already made five splitter stands, which enable technicians to securely separate an engine from its gearbox.

Buying splitter stands had been an expensive proposition, but now the company has its own supply and has already sold one to the European Aeronautic Defense and Space Co., which has military and commercial operations and includes Airbus.

To further its in-house operations and diversify, C&L purchased a 1,200-degree Celsius kiln that bakes carbon buildup onto fuel injectors. The injectors are then checked to determine whether fuel flows through them properly under those conditions.

"That's big business," Kilgour says. "We have a couple of bids out to other repair shops to do their fuel injectors."

And four months ago, C&L bought a specialized welder that enables it to make alloyed materials that will allow the company to fix some parts that once had to be sent out for repairs.

The company still has to send out some parts, such as landing gear, but Kilgour says it is working to reduce what it sends out.

C&L maintains an inventory of 50,000 lines of parts, from bolts to 1,800-horsepower engines. The parts are cataloged in a database that contains photographs and paperwork certifying that the parts meet serviceable standards so customers can see exactly what they are getting.

With so much investment, expansion and growth, Kilgour is confident his company will increase its market share. Last year, C&L was certified as a repair station by the European Aviation Safety Agency, an arm of the European Union.

The first repair of a European plane in Bangor was scheduled for December, with more expected to follow.

Airplane repairs are so expensive in Europe, Kilgour says, that even with the cost of ferrying a plane to Bangor, C&L can do repairs and overhauls cheaper than they can be done across the ocean.

"I see that as a big market," he says.

Attracting investment to Maine

As Telford's operation did, the presence of C&L Air Services benefits the airport, and the local and state economies.

"They are bringing business to Bangor that would not come here if they were not here," says Rebecca Hupp, director of Bangor International Airport. "In that sense they are bringing in money from outside the region and from outside the state."

Her predecessor at the airport, Ziegelaar, concurs, saying, "The ability to attract revenues from outside its borders is a critically important aspect for Maine's economy."

The company leases space at the airport, and customers who bring planes to be worked on pay landing fees.

C&L now pays $88,322 a year to lease the space in what is called the 600 area at the city-owned airport, says Risteen H. Masters Bahr, the airport's marketing manager. For the 12 months ending in October, the city billed C&L $139,748 for fuel and miscellaneous ground services.

Although that is a relatively small portion of the airport's overall annual budget of $14 million, Hupp says C&L's greatest impact may come from the economic boost of its skilled laborers.

It's the ripple effect that comes with employees living and spending in the area, not to mention paying taxes.

Kilgour says he tries to patronize local businesses as much as possible, such as a seamstress in the Bangor area who measures and makes the leather seat coverings for planes that are being refurbished.

Planning for growth

Success is creating some problems for the company. Space problems.

The company has added shelving, some of which reaches almost to the ceiling, for parts that come in daily. A wide corridor has been remodeled to add office space.

Kilgour projects that his company will need an additional 25,000 square feet. He, the airport and city officials have discussed expanding at his current location — which Kilgour sees as preferable — or into vacant hangars elsewhere at the airport. Hupp says one alternative location is the former American Eagle maintenance hangar at the airport.

Kilgour says he has been frustrated by the limited funding mechanisms and incentives available, although Hupp and a city official say they are looking at options.

"We are working with him to evaluate opportunities to get the space he needs to expand," says Tanya Pereira, business development specialist with Bangor's Department of Community and Economic Development.

"If we get a bigger hangar, we can take on bigger aircraft, and we definitely will have to have a lot more people," says Kilgour, who thinks it's possible that such growth could mean 40 more jobs.

Comments