An industry, changed but still viable: One man's tale of Maine manufacturing

If you need a storied perspective of Maine's manufacturing industry over the last few decades — with all the ups and downs included — just speak to someone like Alan Dorval.

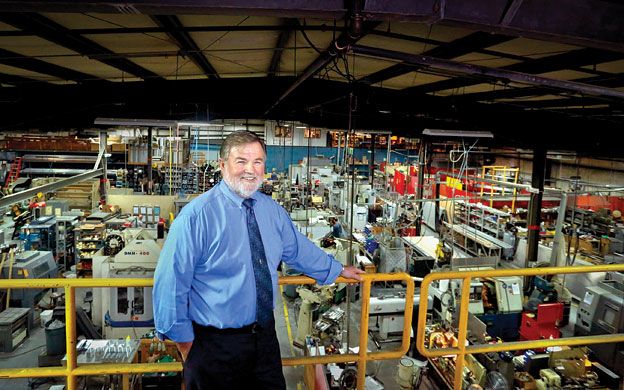

Just after graduating from high school in 1972, Dorval was busy with his hands as a machine shop apprentice for the Winslow-based Mid-State Machine Products, a company that would transform over the next four decades and where he would climb the ranks to eventually become CEO.

Dorval can't tell the story of every manufacturer in Maine, but his is one worth telling. It's the story of how a company can grow and survive through a changing and sometimes turbulent economic environment and how a company can succeed by focusing on teamwork, customer service and continual improvement.

Dorval has since left Mid-State Machine — which is now known as Midstate Berkshire after parent company Precision Partners merged it with a Massachusetts-based company in 2011 — but his attitude about the viability of manufacturing has not changed.

“I think manufacturing is going to make a resurgence,” he says from his office at Gorham-based MEGA Industries, where he now works as operations manager. “Not the high-volume production that maybe goes to the automotive sector, but the things with a little more complexity, things that need high levels of customer service, the things that are connected to innovation.”

In other words, discrete manufacturing — a branch of manufacturing that focuses on lower-volume production of highly customized parts — will continue to require human input in the face of industry's growing utilization of robotic equipment.

MEGA Industries mostly focuses on providing electronic waveguide components to global science laboratories, including the Swiss complex that contains the Large Hadron Collider, the largest and most powerful particle accelerator in the world.

Mid-State Machine, on the other hand, has focused on manufacturing parts for a variety of uses, including military land- and sea-based weapon systems, magnetic resonance imaging devices, flat-panel televisions and offshore well-drilling equipment.

Dorval says while he was there, Mid-State Machine mostly held contracts with customers in five-year intervals and they often came to the company because they may have not had the internal capacity to produce a particular part. So the company was there to help other manufacturers when they needed it the most.

Dorval recalls a time when Mid-State Machine successfully landed a contract with a Texas company. On the surface, it would seem like an odd fit, geographically. But, Dorval says, his company offered a “best-value solution” that convinced the manufacturer that it would make sense to contract out to a company in Maine.

“We didn't try to sell on price. We sold on quality, on-time delivery, keeping our word and standing behind our products. I call these competitive differentiators,” Dorval says, recalling the lessons the company's founder, S. Douglas Sukeforth, imparted on him and others that have helped Mid-State Machine keep a steady flow of contracts. “You go offer a best-value solution and you can get paid for it.”

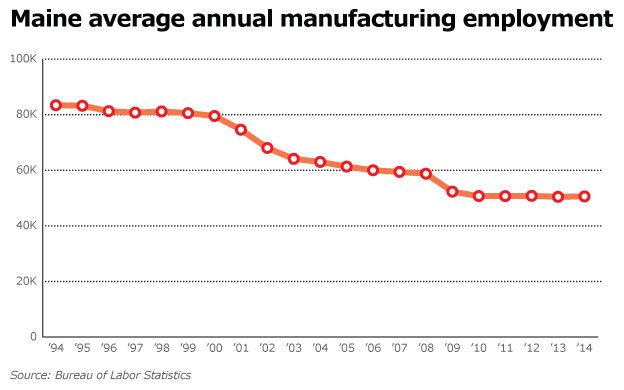

Though Dorval has led a prosperous career, the manufacturing industry on a national and state level has drastically changed over the years. In the last two decades, Maine manufacturing jobs declined by 38%, from 83,000 in 1994 to 51,000 this year, according to the federal Bureau of Labor Statistics.

As the Maine Center for Workforce Research and Information notes in a July 2012 research brief, the manufacturing industry's substantial change in employment has been a result of “shifting buying patterns related to demographic trends, technological advances, international competition and a wide range of other factors.”

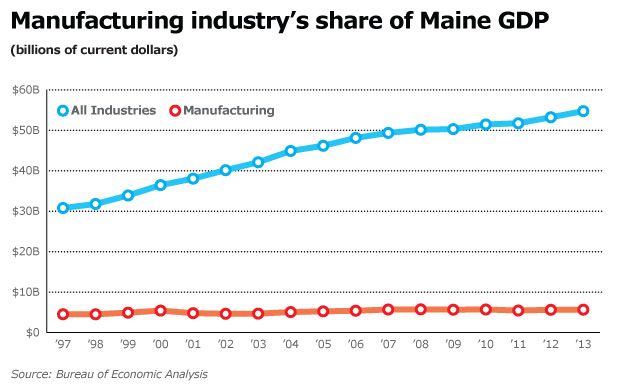

Despite employing fewer workers, the state's manufacturing industry has grown, when measured by the value of its gross domestic product, from $4.5 billion in 1997 to $5.6 billion in 2013, according to the Bureau of Economic Analysis.

During the last 20 years, the largest drops in Maine manufacturing employment occurred between 2000 and 2003, in part because of 9/11, and between 2008 and 2009, at the depths of the recession.

Mid-State Machine got hit particularly hard during the early 2000s, Dorval recalls. Revenue declined by two thirds, from nearly $82 million in 2001 to $26 million in 2003, and the workforce was cut in half, to around 100 workers.

During the company's downturn, Dorval was promoted from chief operating officer to CEO, giving him an opportunity to turn the company around. And it wasn't the first time Dorval was tasked to do just that.

Almost a decade earlier, in the 1990s, Mid-State Machine wasn't making the kind of returns it should have been making, Dorval says. So the company gave him his first executive role as vice president of operations. He focused on creating a culture that encouraged teamwork and continual improvement, Dorval says. In turn, Mid-State Machine was able to double its operating income to $30 million in 1995.

By the early 2000s manufacturers were not only facing an economic downturn but also the rise of “offshoring” and the advent of digital e-auctions, which forced contract manufacturers to become more competitive with their pricing (therefore driving down margins).

In 2006, after performing well on a smaller military contract with Honeywell International, Mid-State Machine received a larger contract with Honeywell to produce engine parts for the M1A1 and M1A2 Abrams tanks for the U.S. Army. That, in turn, prompted Mid-State Machine to add 65 jobs and invest $13 million in a facility in Waterville. Revenue grew to $91 million in 2007, a large increase from the company's low point in the early 2000s.

But large contracts aren't the only factor in becoming successful, Dorval says. Manufacturers also rely on a skilled workforce that is sometimes hard to come by — an issue that has continued to haunt the industry.

“[Mid-State Machine] passed on large projects, multi-million dollar projects,” he says, because company wasn't able to hire enough people.

While the state has made much progress in workforce training efforts, even with some help from Mid-State Machine, Dorval says the manufacturing industry still needs to find a way to convince Maine youth that it's an industry worth pursuing for jobs. One such effort by the Manufacturers Association of Maine, called “Dream It. Do it. Maine,” is seeking to do just that by reaching out to students at middle schools, high schools and colleges.

Dorval says he's been on a lifelong campaign to promote manufacturing. And if anyone can prove that it's still a viable career, it's him.

“I've spent my lifetime making a tremendous living, taking care of my family, [putting six children] through college,” Dorval says. “All of this happened because of my career in manufacturing and I still believe it to be a viable option for years to come.”

Read more

'He wheeled and dealed': An interview with Mainebiz founder Jon Whitney

Maine's mix of colleges and universities have created an 'education hub'

Mergers and regulations: Two decades of change in banking

Health care crossroads: Rising costs coupled with need to be affordable

Oil, propane expected to remain stalwarts as Mainers try new energy sources

Growth engine: Faster broadband seen as essential for Maine's economy

Forest products industry puts $8 billion into Maine's economy

Know your farmer: Locally sourced food trend buoys Maine farms

Groundfishing aground? The rise and fall of Maine's offshore fishing industry

Decades of tide changes: Investments help Bath Iron Works maintain its shipbuilding prowess

Reflecting on 20 years: Other 20-year-old companies look back

Mainebiz presents a 20-year retrospective of doing business in Maine

'He wheeled and dealed': An interview with Mainebiz founder Jon Whitney

Mergers and regulations: Two decades of change in banking

Health care crossroads: Rising costs coupled with need to be affordable

Oil, propane expected to remain stalwarts as Mainers try new energy sources

Growth engine: Faster broadband seen as essential for Maine's economy

Forest products industry puts $8 billion into Maine's economy

Know your farmer: Locally sourced food trend buoys Maine farms

Groundfishing aground? The rise and fall of Maine's offshore fishing industry

Decades of tide changes: Investments help Bath Iron Works maintain its shipbuilding prowess

Reflecting on 20 years: Other 20-year-old companies look back

Mainebiz presents a 20-year retrospective of doing business in Maine

Gorham manufacturer acquires N.H. company as part of 'aggressive growth strategy'

Comments