Local power: Peregrine Turbine's new approach to distributed energy generation

When Peregrine Turbine Technologies LLC first asked Mid-South Engineering Co. for help with its new turbine engine, the engineering consultancy did what engineers do best: they tore into the design, researching all aspects of its feasibility and deciding if they wanted to be involved in the project.

“We did,” recalls Eldon Doody, director of operations in Mid-South Engineering's Millinocket office. “We believe they are working on disruptive technology that could really have a big impact on the costs to generate electricity, whether it uses natural gas or biomass,” says Doody of the turbine, which also can be used in applications from aerospace to marine vessel propulsion. He adds that his company and Peregrine Turbine already have been talking to potential first installations, such as Brunswick Landing, Maine gas and electric utilities and various people in state government.

Peregrine Turbine's first target for its Peregrine Engine — the company expects to complete a prototype 2016 — is distributed energy generation, where power is generated at the point of consumption rather than centrally, potentially saving the cost and inefficiency of energy transmission and distribution over long distances. Distributed energy in itself can disrupt the market: last spring, Central Maine Power and renewable energy advocates sparred over the utility's plan to raise monthly charges on businesses and homes that produce their power by solar, wind or other renewable energy sources connected to the electric grid.

Yet distributed energy systems are making inroads in Maine and other areas of New England. A 2013 report by Synapse Energy Economics Inc. of Cambridge, Mass., found nine community-based renewable pilot distributed generation projects in Maine, with a total installed capacity of 24.2 megawatts. The report predicted Maine will see little growth in such systems, however, because the state's policies to promote distributed generation are not as aggressive as in most other New England states. “We anticipate that Maine will continue to experience modest growth in distributed generation installations and — barring the adoption of new, more aggressive policies — could expect to see up to 70 megawatts by 2021,” the report's authors concluded.

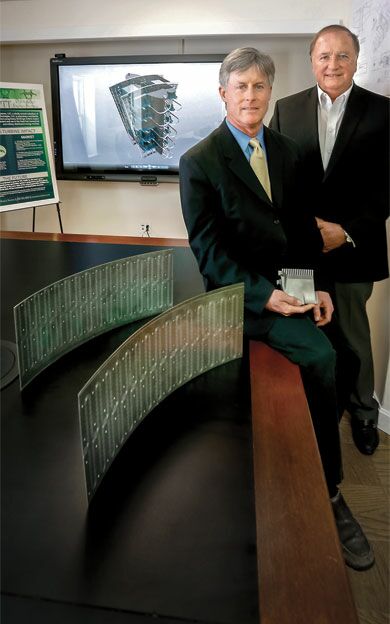

But David Stapp, CEO and chief technology officer at Peregrine Turbine, believes his new turbine could be a game-changer. He sees his company's technology as able to rival electricity prices of natural gas-fired, combined-cycle plants, which are popular now in the power industry. The difference is scale. Combined-cycle plants are typically for large cities like Los Angeles, for example, generating around 400 megawatts of electricity at high efficiency and low cost of about 5 cents per kilowatt hour, he says. Stapp expects the Peregrine Engine to produce electricity at 6.7 cents per kilowatt hour.

“With our engine, our efficiencies and capital costs are in the same ballpark as a natural gas-fired, combined-cycle power plant,” says Stapp, whose company is located at the Wiscasset Airport. “But because we're [generating electricity] at the 6 megawatt scale, you can park this [turbine generator] in the community where the power is being consumed. You don't have to pipe it over the grid.”

The idea, Stapp says, is for municipalities to own their transmission systems and use a Peregrine Turbine system to generate electricity and avoid transmission and delivery costs. Such delivery costs can make up half of an electric bill. For example, a recent residential bill from this writer totaled $71.22 for 459 kilowatt hours of electricity, with $36.52 of that going toward the delivery charge and $34.70 to the Standard Offer Service electricity supply.

Stapp is now talking to potential first installations for the technology, including Brunswick Landing and Wright-Patterson Air Force Base in Dayton, Ohio. In addition, the company is considering getting space in Brunswick Landing, because there is a jet engine test cell there that it intends to use.

Kristine Schuman, business development coordinator for the Midcoast Regional Redevelopment Authority, became familiar with the Peregrine Engine in her former role as a governor's account executive in the Department of Economic and Community Development. While she says she cannot comment on any possible use of the company's system at Brunswick Landing, she says, “The technology they have is going to be something big. It has multiple uses and could be a breakthrough for energy power generation and different applications.”

Old technology, new use

The Peregrine Engine combines an open gas generator with a closed cycle turbine that uses super critical carbon dioxide, or SCO2, an organic solvent that is commonly used to decaffeinate coffee. Stapp says the power generation industry has been interested in using SCO2 to improve engine efficiency, which has hovered around 30% to 35% in the aircraft industry for several decades.

“So we didn't invent the idea of using this in an engine,” he says. “The problem is that others couldn't figure out how to use any air-combustible fuel as the heat source. We figured out a thermodynamic cycle that would permit us to do it.” That means capturing heat from air-combustible fuels like natural gas to improve the efficiency of the turbine. Stapp says the Peregrine Engine's efficiencies should be around 45%, based on its analytical models.

Doody of Mid-South Engineering said an engineering physicist on staff who has worked in the power industry his whole career created engineering models that replicated the efficiencies Peregrine Technologies is claiming.

“One of our guys did a lot of research and found SCO2 technology has been around, but it was how they configured the system that was different,” he says. “Getting the first system running is the challenge, technically and financially, but finding sites to install distributed energy systems will be relatively easy.”

Mid-South will also work to attach the Peregrine Engine to existing energy infrastructure, such as adding electrical transformers and heat exchangers to make a complete local power plant.

Doody adds that many municipalities would like to have their open transmission systems to run electricity, as would industrial parks. He adds that the cost of the system is not yet set, but it should not be that different compared to traditional systems.

Peregrine Technologies also has drawn interest from military complexes, which want a sustainable energy source. “The Air Force is interested in our technology as a power generator,” says Stapp. “There is a thrust in the military for base energy security.”

Better fuel efficiency

The origin of the Peregrine Engine traces back to 2011, when Stapp started working on advanced concepts for aircraft engines, with an eye towards improving their fuel efficiency. “Though it's a wonderful machine that's capable of producing lots of power in a small, lightweight package, a turbine engine is not known for fuel efficiency,” he says. “In an age where the cost of fuel is so high and where the sensitivity to emissions is so high, as an engineer I thought the time had come for someone to do some serious groundbreaking work.”

He says the inefficiency has to do with the ability of a heat engine to convert heat into mechanical power. Every engine currently used for transportation takes heat and converts it into mechanical power. The efficiency with which a machine does that conversion largely depends on the temperature after combustion, the temperature of the exhaust and the difference between the two, he says. The thermodynamic cycle determines how much chemical energy in the fuel gets converted to mechanical energy, and how much of it gets turned into waste heat exhaust.

Not much has changed in turbine engine technology since the 1960s, Stapp says, and the technology is so mature that any incremental improvements are very difficult and expensive. With efficiencies averaging 33%, that means the other two-thirds of the fuel that the engine burns is wasted. Stapp claims the first version of the Peregrine Engine, which will run on natural gas, will be 45% efficient.

The differentiator in his design is that air makes a single pass through the Peregrine Engine, but unlike other engines, the heat does not pass through. Instead, the heat is retained in the engine through a process called a “thermal flywheel,” where the SCO2 fluid moves continuously in a circle. It's a way of recapturing heat that otherwise would go into the atmosphere as exhaust, and thus makes the engine more efficient, he says.

Stapp already is looking at broader applications, even within the power generation niche. He says waste heat from the system could be used to create refrigeration using a so-called adsorption chiller. That chiller could be combined with the Peregrine Engine so customers could have both electric power and cooling. One application he says would benefit: the cloud computing server farm at Brunswick Landing.

Another use is to add different fuels. A big target for Stapp is burning biomass, because of the large amount of biomass available in the state's forests.

“Our technology gives us the ability to generate electric power at the same price using biomass as we would to generate it using natural gas,” says Stapp. That's a big plus, he adds, because currently biomass is only affordable with government subsidies.

Doody says there's potential as well to piggyback the turbines to create larger power installations. “We've taken a preliminary look if you could take the modules [turbines] and have from two to five of them side-by-side, sharing the same site infrastructure. It looks like that is more than feasible,” he says.

Looking for partners

Peregrine Turbine is one of several companies founded by Stapp, a former GE Aircraft Engines engineer. Peregrine Consulting Inc. was founded in May 1996 in Massachusetts, but he moved it to Maine in 1999. He started Peregrine Turbine in April 2012 to act as a parent company that would hold the intellectual property for inventions such as the turbine. In December 2014 he founded PTT Distributed Energy Systems LLC as a subsidiary for the distributed energy application of the turbine technology.

Parent company Peregrine Turbine already has raised $4.3 million, and is in the middle of raising another $5.7 million in equity. Peregrine Turbine also has a $150,000 Phase I Small Business Innovation Research grant and has been selected for a Phase III award. PTT Distributed Energy Systems also is raising equity, having sold a little over $1 million of a $4.5 million round. Stapp declined to name investors in the equity rounds.

Stapp plans to found other subsidiaries as other applications for the technology emerge. The idea is to commercialize products by seeking joint ventures between the subsidiaries and well-established companies with market share, the ability to support sales and service and perhaps also bring manufacturing expertise and technology.

“PTT Distributed Energy Systems does not have employees,” Stapp explains. “The objective here is to create the engineering and business development capacity at the parent level, and service the subsidiaries from the parent.”

He is working now to publicize the technology. “We've launched a public relations and messaging campaign last year,” he says, “and I spoke at the Turbine Engine Technology Symposium in Dayton, Ohio [September 2014], which is a Department of Defense event for aircraft engine manufacturers and military. We rolled out our technology there and then in the same week I spoke at the Supercritical CO2 Power Cycles Symposium in Pittsburgh. It's the beginning of making the industry aware of who we are and what our technology is.”

Another goal for the company is to create jobs in Maine and keep its technology in the state. It has hired two recent graduates and an intern from the University of Maine at Orono. “All of our investors are told up front about the state of Maine objectives,” says Stapp. “The technology stays here.”

Read more

Comments