Plan for bio-based heating, power system advances at Millinocket’s One North

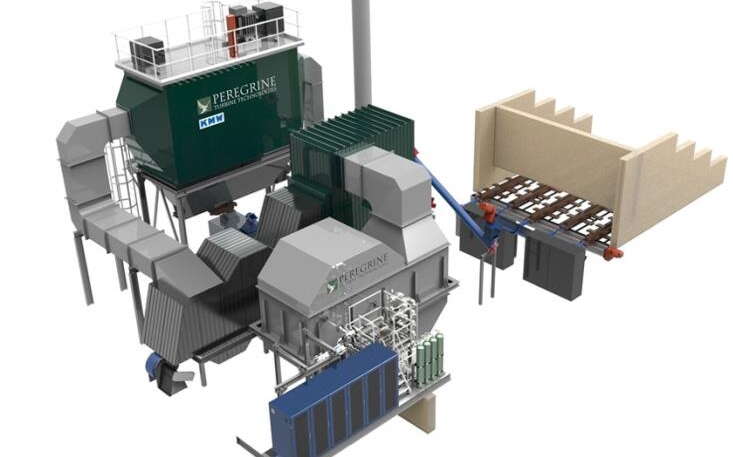

Rendering / Courtesy, Peregrine Turbine Technologies

Peregrine Turbine Technologies in Wiscasset says its super-critical carbon dioxide energy conversion turbine technology will provide combined heat and power to multiple buildings at One North in Millinocket.

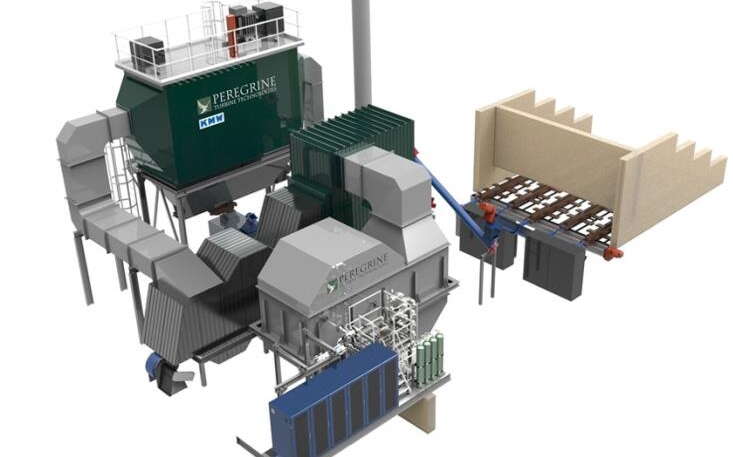

Rendering / Courtesy, Peregrine Turbine Technologies

Peregrine Turbine Technologies in Wiscasset says its super-critical carbon dioxide energy conversion turbine technology will provide combined heat and power to multiple buildings at One North in Millinocket.

Plans have advanced to install a first-in-the-world heating and power system at the One North industrial campus being developed in Millinocket.

Fueled by the wood waste of Maine forests and cycled through a “super-critical carbon dioxide” energy conversion turbine, the system is touted as an energy-saving breakthrough.

Peregrine Turbine Technologies in Wiscasset said it is collaborating on the project with KMW Energy Group, an Ontario manufacturer of biomass combustion systems, and Our Katahdin, the nonprofit that owns One North, which is a former Great Northern Paper mill site.

The three entities last week announced their intention to collaborate on the location, installation and operation of Peregrine’s super-critical carbon dioxide energy conversion system, integrated with KMW’s reciprocating grate and modular biomass gasification and combustion system.

The goal is to provide combined heat and power to multiple buildings on Our Katahdin’s Innovation Hub campus. The combined system is also expected to produce biochar for agricultural and other high-value applications.

Once up and running, the integrated systems are expected to be the world’s first combined heat and power system fueled by biomass and enabled by super-critical carbon dioxide, or sCO2, according to a news release.

Financing for the project includes support from the U.S. Department of Energy through congressionally directed spending of $2.5 million.

What is sCO2?

Super-critical carbon dioxide occurs when carbon dioxide is held above both a critical temperature and a critical pressure, according to the U.S. Department of Energy.

The substance acts like a gas, but has the density of a liquid. In a supercritical state, small changes in temperature or pressure cause dramatic shifts in density, making sCO2 a highly efficient working fluid to generate power.

Power cycles based on super-critical carbon dioxide as the working fluid can produce thermal efficiencies at lower cost than even advanced steam-based power systems. That can mean reduced need for fuel and water, lower capital and electricity costs, affordable and scalable power generation from local heat sources, and a more compact design and footprint.

Peregrine Turbine Technologies

Peregrine is a limited liability company formed in April 2012 to focus on the development and deployment of advanced sCO2 turbine power generation, energy storage and propulsion systems.

Founded by David Stapp and Robert Brooks, the company has received awards from the Air Force Research Lab, Office of Naval Research and Maine Technology Institute toward its development of a sCO2 gas turbine and heat exchanger system for energy conversion.

Stapp, serving as CEO and CTO, invented the Peregrine Engine. His career of nearly four decades includes aerospace engineering, unmanned aerial vehicle design and high-end computer server design and integration.

More recently, the Bremen resident has teamed with Brayton Energy LLC, a New Hampshire research and development firm dedicated to sustainable and efficient energy production, with a specialty in turbomachinery and gas turbine systems

Brooks, Peregrine’s chief development officer and a resident of Stockton Springs, was a principal for Bethesda, Md., private equity company American Capital Ltd. (Nasdaq: ACAS).

The technology behind sCO2 technology has been around for a while. But the company’s goal has been to configure a turbine system that would generate power at a higher efficiency and lower cost.

The use of biomass as a fuel has been a target from the start, due to the large amount of biomass available in Maine’s forests.

Biomass breakthrough

Last year, Peregrine announced it had achieved a breakthrough in developing a biomass solution for clean combined heat and power applications. At that time, Peregrine and Our Katahdin announced a memorandum of understanding outlining their plan to establish a demonstration project of the Peregrine system at One North, with the goal of providing renewable electric power and district heating to Our Katahdin's planned "Innovation Hub" at the One North campus.

Peregrine’s sCO2 technology was deemed a strong fit with biomass applications, with the expectation that the system could at least double the efficiency of other heat and power systems.

The system is modular and can be configured to optimize specific application requirements. Projected costs and efficiencies are expected to make sustainable biomass energy competitive with other mainstream energy sources.

The system is expected to produce thermal energy and 1 megawatt of electricity, equating to about the same amount of electricity consumed by 400 to 900 homes in a year.

The scalable system will also be capable of producing biochar on a continuous basis.

With capacity of 1,500 tons per year of biochar, the equivalent of 4,200 tons per year of CO2 will be permanently sequestered and the biochar can be used locally in forestry and agricultural applications.

Biochar is the solid material obtained from the thermochemical conversion of biomass in an oxygen-limited environment. Uses include soil amendments, animal bedding, environmental remediation, stormwater management, and as an additive to cement and asphalt. Carbon sequestration is an added benefit.

Peregrine’s sCO2 conversion system was developed in collaboration with the Brayton Laboratory team of Albuquerque, N.M.-based Sandia National Laboratories, which serves the U.S. Department of Energy.

At the center of Peregrine’s technology is a “heat engine” that can operate on all air combustible fuels, including biomass, bio-gas, refuse derived fuels, hydrogen and high-grade heat sources including advanced nuclear and concentrated solar.

No matter the energy source, Peregrine’s sCO2 enabled conversion system uses less of it, according to the company.

0 Comments