Stonyvale Farm converts waste to power with new system

The future of a fifth-generation Maine farm is in the crapper, and it could be the best business decision the family has ever made.

Stonyvale Farm in Exeter, owned by the Fogler family, is a dairy farm with over 1,000 milking cows producing more than 22 million pounds of milk per year.

Those figures pale in comparison to another bovine byproduct: Each year, Stonyvale's cows produce up to 97 million pounds of solid waste.

Because of its fat and protein content, Stonyvale's milk is easy to sell to cooperatives like Dairy Farmers of America. The manure is a different story. While manure is useful for fertilizing livestock feed, the dairy was getting only one use out of its most abundant resource.

"There was a discussion about how to really improve our nutrient management practices on the farm," says Adam Wintle, a cousin to the Foglers and a commercial real estate developer who specializes in financial analysis and holds an engineering degree from University of Maine.

The result of that family discussion three years ago is Maine's first-of-its-kind, $5.2 million anaerobic digestion system, a renewable-energy process that converts animal and food waste into methane-rich biogas. Collected manure is fed into a digester where heat is applied to break down the material into biogases. Those gases then fuel a 16-cylinder, 1,500-horsepower engine that produces 24,000 kilowatt hours per day — enough electricity to meet the needs of 800 households.

"This digestion idea was particularly appealing to me, and it certainly didn't hurt that my family was involved, so my motivation was to explore this idea and see if there was any way I could help propel it into a real project," says Wintle.

The system, which went online in December, also produces heat by trapping exhaust gases from the engine to heat antifreeze, which is pumped back into the system to heat the digester and other parts of the system. Producing almost 4 million Btu of heat per hour, the system can generate the equivalent of 700 gallons of No. 2 heating oil per day. It also produces some very marketable byproducts — a low-odor chemical effluent that can be used as a fertilizer, and a low-cost, organic bedding for livestock

"That source of energy is just constantly there, and it has a far greater level of consistency than the more sporadic [sources] like wind or solar," says Walter Whitcomb, commissioner of the Maine Department of Agriculture, who sees enormous potential in anaerobic digester energy systems for agricultural operations of scale.

"I've seen these [systems] across the country and this is one of neatest in terms of engineering features," he says. "But it takes some expertise. This is not something you do after hours. There really needs to be a focused effort and it takes a real management person."

Launching the business

Wintle's financial and commercial development skill set gave him a unique perspective on the biogas market, as well as the financing challenges of such projects and their huge potential returns. In 2009, he founded a renewable energy development firm under the name Biogas Energy Partners.

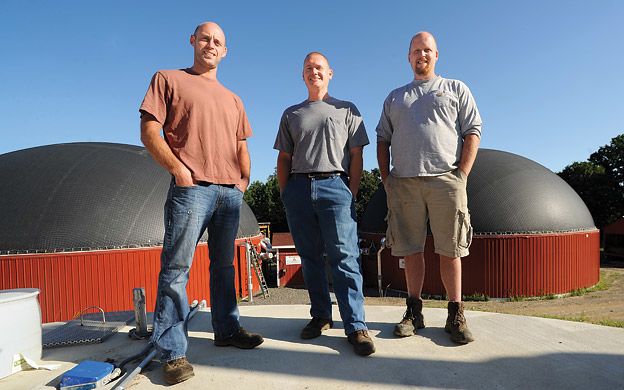

Three years later, the system is up and running as a family affair. Wintle heads up Biogas Energy Partners as managing director while his brother, John, acts as project and facilities manager for the farm's digester under the banner of Exeter Agri-Energy, a subsidiary of Stonyvale Inc. EAE handles day-to-day operations while BEP steers the project through economic, political and regulatory challenges inherent to any renewable energy project.

The family collaborative has succeeded so far in generating extra revenue by selling its excess electricity while lowering its own operational costs. Adam Wintle secured a 20-year, fixed-rate power purchase agreement with ISO New England that pays the EAE partners 10 cents per kilowatt hour. The agreement helps to ensure long-term economic sustainability for the farm by mitigating the cyclical nature of today's dairy market.

"Milk prices are extremely volatile," says Wintle. "They don't change 10% or 20% year over year, it could be 50%. That makes it very difficult to be continually profitable when there are those kinds of bumps."

"What the digester and the fixed rate power contract does is provide a solid, fixed cash stream to essentially hedge out the big risks associated with milk prices," he says. "From a financial standpoint, that's really the benefit to the operation here, and lenders see extreme security in that."

The system also allows EAE to sell renewable-energy certificates to parties interested in offsetting their energy intake. These tradable, non-tangible energy commodities can be sold within the United States with each certificate representing 1 megawatt hour of renewable energy. EAE plans on releasing approximately 8,000 Class 1 REC certificates into the market each year.

"[RECs] are a product that are in increasing demand," says Wintle. "In less than a year, we've seen REC prices rise from $20 per REC to upwards of $50. It's a real home run opportunity if you can work out the economics."

He forecasts the fixed-rate power contract will likely account for 50% to 70% of EAE's business, with RECs drawing 10% to 30% and animal bedding making up 5% to 10% of sales.

"There's also excess heat that we are trying to find an investment for. We use it to heat the digesters, but we still have about half left over," says Wintle.

On the farm

Stonyvale's digestion system doesn't look out of place. Standing 30 feet tall, the building, with its twin silos, bears the familiar red hue of barns everywhere. But its impact has been extraordinary.

The digestion system has allowed Stonyvale to reduce its cow bedding expenses by up to 50%, saving the farm as much as $80,000 a year, according to operations manager Travis Fogler. The chemical effluent produced as a byproduct is expected to replace a majority of the farm's commercial fertilizer, saving up to $100,000 annually, he adds. Plus, as a liquid fertilizer, the effluent "makes nutrients more available and we're able to better manage the ingredients," he says.

Then there are the social and olfactory benefits.

"It smells much better," says Fogler. "We just spread [effluent] two weeks ago. Historically, we've never spread in the summer because of our neighbors. This system allows us to be better neighbors and better utilize the nutrients that are already here."

The chemical effluent produced by the digester has certain advantages over raw cow manure, says John Wintle, who also holds an engineering degree and worked in the pulp and paper and food manufacturing industries. In the digestion process, organic nitrogen is converted into inorganic nitrogen, which is "easier for plants to take up," says Wintle. "If you spread manure, microbes in the soil must break nitrogen into its organic form before it can be taken up."

The installation of the digestion system has not radically changed day-to-day operations on the farm. Manure is still collected by auto-scrapers that sweep the floor of the cow's barn, gathering manure and depositing it in the center of the building before it's pumped out. The only difference is that the manure is now pumped directly into the farm's own power plant instead of a manure storage facility.

A bellwether for other farms?

Although the system seems to work well at Stonyvale, Adam Wintle says precarious finances around such projects prevent digesters from gaining traction at many farms.

"If you look at the social and environmental benefits, the story is quite compelling," says Wintle. "The reason why there are only a little over 100 [digester] systems in the U.S. — despite there being over 70,000 dairies — is because it is so challenging economically to unlock that situation."

In Europe, government subsidies and established power purchase models have allowed such systems to flourish, says Wintle.

"A lot of their governments are funding these by offering 20 to 25 cents per kilowatt hour [to buy the power]," he says.

Vermont's Sustainably Priced Energy Development Program, enacted by the state Legislature in 2005, subsidizes digester projects by guaranteeing upwards of 14 cents per kWh for energy generated by such systems, according to Wintle.

But the history of failed digestion systems in the United States has "given digesters a real black eye," says Wintle.

"In the past, independent dairy owners have tried to cobble together projects based on systems [that were] designed to fail up front because they are inexpensive and don't function well," he says.

"They are in the business of making milk and they mistakenly [approach] these projects as an afterthought when they are really professional development projects that need proper oversight and management," says Wintle.

Wintle's background in finance — he also runs a financial services group called Strategic Equity Analytics based in Portland — was instrumental in lining up funds for the Stonyvale project. "It's a financial engineering exercise to cobble that all together. You have to make the equation work in terms of upfront grant subsidies and back-end power rate subsidies as well as REC sales," he says.

Wintle secured $2.8 million in grant funds from the U.S. Department of Agriculture, the U.S. Treasury Department and Efficiency Maine. The renewable- energy project also received $6 million in loans from Farm Credit of Maine, part of a network of lending institutions that support agriculture ventures.

"If you removed any of those three grant resources or the anchoring power purchase agreement, this project would not be at the finish line," says Wintle.

Moo-ving forward

After operating the plant for a little more than six months, the Stonyvale team is already considering an expansion to double its current capacity to treat an additional 10,000 gallons a day and see the installation of a second 1MW engine generator.

But a decrease in funding options could dictate the partners' course of action. "A lot of federal money has dried up and there is no question that is going to choke development for some time," says Wintle. "It's discouraging, because we have a lot of momentum right now."

Wintle hopes that a state-mandated push toward recycling organic food waste will translate into more business for the farm. "Part of my job is to generate interest in the facility as a disposal outlet for food waste," he says.

Massachusetts passed legislation that will ban food waste from hospitals, universities, hotels, large restaurants and other big businesses and institutions beginning in 2014, with the goal of including residential waste as well.

"I believe within the next 10 years you are going to see a push in residential households to recycle food waste," says Wintle. "That kind of event is definitely going to propel these kinds of opportunities."

He also hopes to lure a business to the farm that's interested in "cheap real estate, a very favorable permitting environment, cheap energy and cheap heat."

Wintle wants to use BEP to export the digester model to other dairy farms, and advise others on financing and power purchase agreements. "Every day we are in operation we learn more and more about the forces that are influencing this entire equation," he says. "We are actively looking for another strong opportunity with the caveat that we understand it will be very challenging to develop another project in the current [economic] environment."

Economic, environmental and social benefits aside, the digestion system brings an added perk to Stonyvale that won't show up on any ledgers.

"There are nine family members here every day," says Fogler. "That's another reason we did the project. It allowed another one to return home to the farm."

Comments