The Fletchers keep western Maine's wood-products industry spinning

PHOTo / Tim greenway

PHOTo / Tim greenway

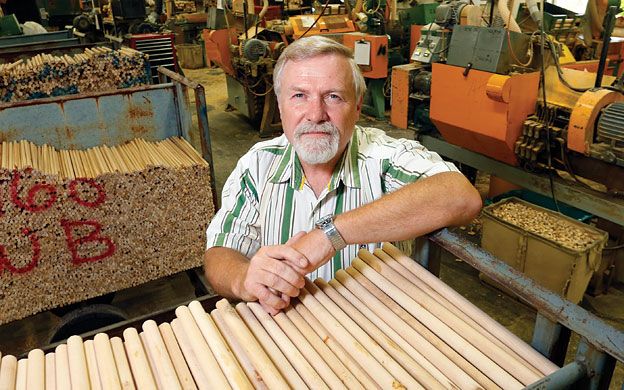

Douglas Fletcher makes it clear that even with his latest purchase of rolling pin manufacturing equipment and a customer list from another mill owner, he's still on the lookout to buy companies or operations that will help his own company expand and grow.

It's a strategy that Fletcher adopted early in his tenure as president of Maine Wood Concepts, a wood turning company in New Vineyard. Fletcher says Maine Wood, which he runs with his two brothers, vice president of operations Jody and vice president of product development Gary, looked to acquire other companies to branch out through the years. The first was a machine shop in Ashburnham, Mass., bought in the mid-1990s. And in 2005, Maine Wood paid about $500,000 to buy the name, inventory and customer list for a file handle it had been making for Lutz File & Tool Co. of Cincinnati. That same year it paid more than $750,000 for Pride Manufacturing's Custom Wood Turning Division, which made smaller-scale wood turnings such as pieces for game boards. And it paid an undisclosed amount for Downeast Woodcraft, an Anson-based maker of cooking spatula handles. There were some smaller purchases as well, but the next large one came at the end of 2012, when it bought the Vic Firth Gourmet division for upwards of $900,000.

“We're wicked excited about this. It opens the door for us to be in the mid-range market,” he says of the rolling pin equipment purchase from Louise Jonaitis, who owns Saunders Bros. and three other mills in Maine. That deal closed Sept. 27. “The new line also will position us to be more lean, to do more with the employees we have so the company can be more profitable.”

Maine Wood also sells high-end Vic Firth rolling pins targeted at gourmets and food-service professionals. They use ball bearings, whereas the mid-range rolling pins use bushings.

“There are a lot of economies to be had by making a less expensive rolling pin,” Fletcher says, noting that a more limited number of people will buy the high-end product. He declined to reveal the purchase price and how much extra business he's projecting, but he expects significant volume. The equipment will be moved from its current location in Greenwood to New Vineyard, and Fletcher expects the first mid-range rolling pins to come off the line by the end of October.

Diversifying by acquisition

The acquisition strategy has worked for Maine Wood, which over the past couple of decades has endured severe price competition from China and flagging interest from hobbyists. Those challenges forced the company to adopt lean manufacturing practices, to consolidate and trim costs, and to expand into new products to grow revenues.

Fletcher, a humble man who says he's about five years from retiring, describes himself as a true Mainer who likes to hunt and fish. He has a hunting camp on 500 acres of woodland and fields near Tantrattle Mountain in Avon, where he and his wife can relax and take in the beauty of the backside of Saddleback Mountain.

“I'm zealous about things I get involved with. I'm honest and pride myself in my honesty,” says Fletcher. “If you can't trust someone, why would you want to hang around with them or do business with them?”

He says that honesty is reflected in the wood turning business as well.

“It's not a cutthroat business. People help each other when someone is in trouble,” he says. Besides, he likes brushing elbows with his brothers at work every day.

And he enjoys having factory visitors guess how each turned part is used.

“What do you think this is for?” he asked, holding up a small peg when Mainebiz visited him this summer. It was a wheel axle for a toy train.

A mountain of sawdust

Fletcher's father, Wayne, and his uncle Earl started Maine Wood when they bought a defunct factory in New Vineyard.

“My dad is a true entrepreneur but I'm not. He saw an opportunity for him to be his own businessman,” says Fletcher, who was in high school at the time, the oldest of five boys. “The day my dad bought the mill in 1971, we started working there.”

The mill came with a couple of Model A pickup trucks, which the boys quickly put into service to carry shoveled sawdust to the back of the factory, where farmers and others would buy it. “The sawdust pile was the size of a small mountain,” he says. Nowadays, biomass and wood pellet makers are quick to snap up the sawdust, which is sold in packages.

“I have to tell you I was as tickled as I could be that my dad had bought the company and we could work together,” he says. He didn't think about his own future opportunities at the company until the early 1980s. He did everything, as did his brothers. All learned how to use the bolter saw, run lathes and ship products.

In the early 1980s, Fletcher started tinkering on the spool machines in the mill that are used to make handles.

“I thought I had found my niche,” he says. But in the late 1980s, he took over as president of the company when his dad retired. “He [his dad] had evaluated our strengths and weaknesses for a while. Everyone asked why they weren't president, but in short order realized the wisdom of dad in putting us in our positions.”

A third generation of Fletchers is now working their way up from the shop floor. One is Doug's son, the other Jody's.

“The generational ties for the company gives us encouragement. We like to see our legacy continue,” says Fletcher.

The company has gotten much more sophisticated since he and his brothers took over: it had 20 employees then, and has 100 now. More complex equipment is in place.

“We're three worlds from where we were before,” he says. “We are making sure to get the right people in the right positions.”

But the fun stuff for him still lies in setting up machines and making things better.

“My brothers and I all have tinkering in our blood,” he says. “I attribute the company's success to that trait.”

Read more

Scientists Kevin Strange and Voot Yin probe the mysteries of regenerative tissue

Josh Shea reflects today's L-A with his magazine and film festival

Chris Kilgour's Telford buyout yields surprising rewards

Masey Kaplan builds a better fundraising tool for schools and nonprofits

Allagash International's Terry Ingram breaks into foreign markets

Tom Hall drives his marketing company and Portland’s technology connections

Sylvia Getman leads The Aroostook Medical Center down a more sustainable path

Gayle Brazeau shepherds Maine's next generation of pharmacists into service

Scientists Kevin Strange and Voot Yin probe the mysteries of regenerative tissue

Josh Shea reflects today's L-A with his magazine and film festival

Chris Kilgour's Telford buyout yields surprising rewards

Masey Kaplan builds a better fundraising tool for schools and nonprofits

Allagash International's Terry Ingram breaks into foreign markets

Tom Hall drives his marketing company and Portland’s technology connections

Sylvia Getman leads The Aroostook Medical Center down a more sustainable path

Gayle Brazeau shepherds Maine's next generation of pharmacists into service

Comments