Processing Your Payment

Please do not leave this page until complete. This can take a few moments.

- News

-

Editions

View Digital Editions

Biweekly Issues

- December 1, 2025

- Nov. 17, 2025

- November 03, 2025

- October 20, 2025

- October 6, 2025

- September 22, 2025

- + More

Special Editions

- Lists

- Viewpoints

-

Our Events

Event Info

Award Honorees

- Calendar

- Biz Marketplace

The business of craft: Thos. Moser Cabinetmakers profits from hands-on, Maine-based production

Photo / Russ Dillingham

Thomas Moser and CEO Bill McGonagle share a commitment to making hand-crafted furniture in Maine. The Auburn manufacturing facility is approaching $20 million in sales this year.

Photo / Russ Dillingham

Thomas Moser and CEO Bill McGonagle share a commitment to making hand-crafted furniture in Maine. The Auburn manufacturing facility is approaching $20 million in sales this year.

File Photo / Russ Dillingham

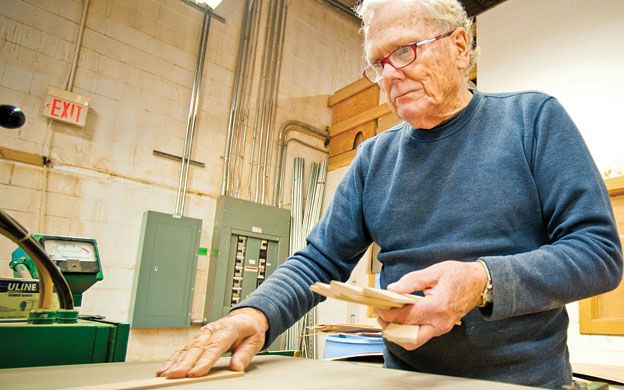

In this photo from 2014, Thomas Moser feeds wood into a planer at his facility in Auburn.

File Photo / Russ Dillingham

In this photo from 2014, Thomas Moser feeds wood into a planer at his facility in Auburn.

File photo / Russ Dillingham

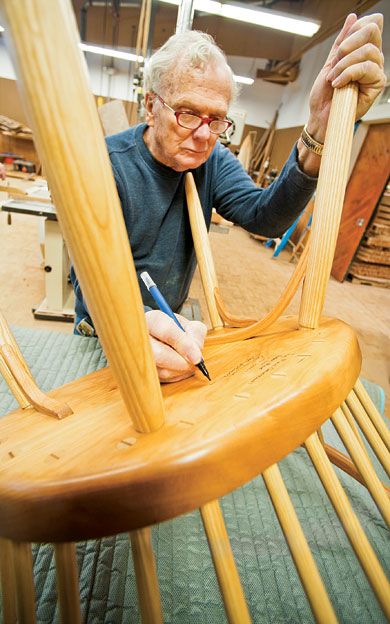

Thomas Moser signs a chair in the furniture company's Auburn workshop.

File photo / Russ Dillingham

Thomas Moser signs a chair in the furniture company's Auburn workshop.

Photo / Russ Dillingham

Jim Wisser checks a piece of Cherry for flaws before cutting for production in the Auburn manufacturing facility of Thos. Moser.

Photo / Russ Dillingham

Jim Wisser checks a piece of Cherry for flaws before cutting for production in the Auburn manufacturing facility of Thos. Moser.

Photo / Russ Dillingham

Inside Thos. Moser in Auburn.

Photo / Russ Dillingham

Inside Thos. Moser in Auburn.

Photo / Russ Dillingham

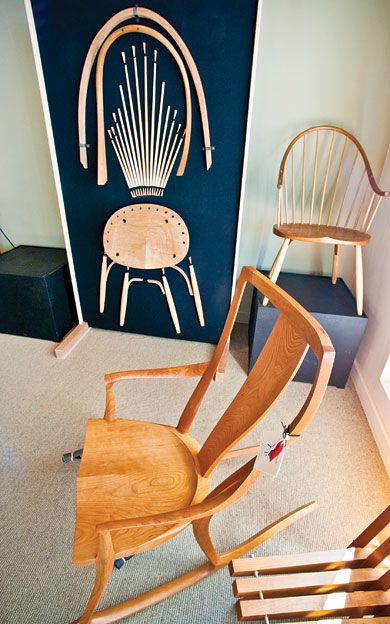

A display in the Auburn showroom at Thos. Moser furniture.

Photo / Russ Dillingham

A display in the Auburn showroom at Thos. Moser furniture.

When Thomas Moser began creating furniture in the 1970s, he did so from an overwhelming desire to build with his hands. He had no preconceived direction or goal to create a business, initially; his reverence for wood and time-honored joinery techniques were his compass points. He was motivated purely by passion and the satisfaction he derived from the work itself.

Forty years later, Moser's passion is still the guiding force behind his Auburn-based company, and the focus on the mystical union of the hand and the wood is the essence of the furniture's appeal. In a rare successful convergence of craft and commerce, Moser and family have created a company that both celebrates artistic precision and produces a highly marketable product.

Thos. Moser Cabinetmakers annually builds close to 7,000 chairs, tables, cabinets, desks, stools, benches and beds. They're revered for their authentic beauty and timeless design and handcrafted in select American hardwoods, sustainably harvested and milled, primarily in the Northeast. The company employs 65 cabinetmakers, both men and women, in its 80,000-square-foot workshop and another 70 people in sales, administration and other areas. There are currently six showrooms, from Freeport to San Francisco, with a seventh opening in the Georgetown neighborhood of Washington, D.C., in January. Gross revenues, from both residential and commercial orders, will climb towards $20 million this year.

With increased orders from showrooms that opened in 2012, in suburban Philadelphia and Greenwich, Conn., a targeted focus on expanding its customer base, and a well-received new product line, the company is more profitable this year than ever before. Yet Thos. Moser has had its share of lean years.

“The recession had significant impacts across housing-related industries and we weren't immune. We lost 30% of our top-line revenues. We flattened out the organization, did some restructuring. We did not cut people from the workshop,” says CEO Bill McGonagle, a former chief financial officer at Tom's of Maine. “This is a family of entrepreneurs. We figured out how to get it back. We focused on our core, which is high-end furniture built to last a lifetime.”

Director of Marketing Scott Wentzell emphasizes the importance of the showrooms, combined with select direct-mail campaigns. “Our product really benefits from being seen and felt, and opening a showroom doesn't cost us a lot if we find the right space,” Wentzell says. “Getting people to engage with the product itself can be a high hurdle, especially in this electronic age. To ask someone to get in a car and drive to a physical space is asking a lot. But our showrooms have significant rewards in terms of converting people who like our product into customers.”

Retail customers become commercial clients

The company estimates 40% of its sales are with repeat customers. Residential customers boost the commercial operation, Moser Contract, which is run by Tom's son Aaron. “The commercial buyer is almost always a residential customer first, who's rooting for us to get the project,” Aaron says. “There's an emotional element to our product, it's not just about the cost. The companies we may be competing with don't have that. The niche we're in, we're one-of-a-kind.”

“The two arms of the business work really well together,” Aaron adds. “Our average order on the retail side is $4,000. On the commercial, it's $250,000. Moser Contract is just 15% of our total business, but that helps cover a lot of overhead, and it brings us a lot of exposure. We want it to be a support model, not our core.”

Moser has been selling a corporate line for 20 years. Its furniture graces the halls of universities, company boardrooms and hundreds of libraries, including the George W. Bush Presidential Library and Museum in Dallas. “There was a period where I think we did every school library in North Carolina. In Maine, the first library was the Margaret Chase Smith Library in Skowhegan,” Aaron says.

The furniture is also in the University of Southern Maine's Glickman and Osher Map libraries, at Kennebec Valley Community College, the Bangor courthouse and the offices of Pierce Atwood, SMRT Architects and Baker, Newman and Noyes, to name a few.

Sales to Maine residents represent only 5% of total volume, but the Freeport showroom is a busy one, due to various factors: out-of-state visitors, vacation home owners, kids at nearby colleges and summer-camp traffic. “This a very special area for this brand,” McGonagle notes.

Aaron feels the furniture's provenance is integral to its appeal — the fact that it's made in Maine and, even more importantly, that it's made by hand. Each piece is made to order and built by a single craftsperson, start to finish, including the signature. “The human element adds significant value to the product. Furniture created by hand has meaning. People today care about where their purchases come from, how they were made, what their dollars are supporting,” Aaron says. “We've always been doing things this way — now the world is seeing it through our lens. It's the younger generation that's driving this, and that's our future.”

The shop utilizes limited technology. “We're balancing craft and technology,” Aaron explains. “Our craftsmen's eyes are focused on the details, without investing in the inventory. We could cut our costs in half and make more furniture faster, but we've found that if we do what's right, we'll be profitable.”

Turnover is relatively low; many cabinetmakers are 20-year veterans. Tom is enthusiastic about the pool of talent in Maine. “The greatest asset we have here is the people, who have a passion and a family history of working with their hands.”

Tom is dedicated to keeping the product made in Maine and sourced entirely in the United States, but he laments he can't have wood milled here. “We don't have the mills in Maine that can do the kind of work we need. We have no shortage of wood, and we have the labor, but we haven't had a government that's been responsive to manufacturing,” he says, ticking off a handful of other wood product manufacturers who have gone out of business or moved to Asia.

CEO McGonagle says the company is emphatic about its Maine roots: “We'd rather close up and go home than go overseas,” and equally emphatic about sourcing supplies and tools in the states, including a new $350,000 router. “We're choosing to spend our money here and we're proud of that.”

Forging a customer connection in the workshop

A unique customer-in-residence program allows a limited number of customers to spend a week, working side-by-side with a Moser cabinetmaker, building an order. It's been a very popular opportunity: more than 285 devotees, paying from $6,300 to $14,000 apiece, have participated and more are booking for 2015 and farther out. The experience has strengthened customer bonds, deepened pride of workmanship for the cabinetmakers, and created what Aaron calls “a halo effect” for the company.

It's sparked similar programs with the Dempsey Center in Auburn, and with St. Timothy's School, a private girls' school in Maryland, which has worked with Moser on a number of installations. Students from the school have come to the shop as part of their curriculum. “These girls who have never held a tool in their life are learning to make furniture,” Aaron says, “and they love it. It's been a very moving experience for us to work with them.”

Looking towards the future

In 2013, Thos. Moser named Adam Rogers director of design and product development, the first non-family member to sit in that chair. Rogers is an architect-turned-furniture-designer in his 30s who came to intern with Tom and stayed on. His new Cumberland line is selling well, with $250,000 in sales in two months. “That's high for us,” McGonagle says. Aaron Moser foresees Rogers' style connecting with a younger clientele. “He comes from the same mold [as we do] in terms of his values, but he views the design world with a slightly different lens.”

“Tom is not retiring,” Aaron adds, though as the company's namesake approaches 80, there are “daily” discussions as to how his shoes might be filled. “He's healthy and he considers this business his fifth son. He's here 2-3 days a week and continues to lead by example.” Currently he's creating, with son Andrew, a limited number of outsized cherry and walnut flags, inspired by the opening of the Washington store. U.S. Sen. Susan Collins has requested one.

As the company looks towards its future, it intends to stay firmly rooted in the past. Aaron says, “It's not our role to be a furniture company, it's about honoring the history of craft.”

Wentzell adds, “People are looking for that, for things that are not made in China, but that are made here, by people who work with their hearts as well as with their hands.”

Read more

John Holden takes helm of Lewiston-Auburn Economic Growth Council

Retail footwork: Lamey-Wellehan, battling competition, remains 'fast on our feet'

Retail footwork: Lamey-Wellehan, battling competition, remains 'fast on our feet'

Another thing about Maine: It doesn't shut down after Labor Day

Mainebiz web partners

The Giving Guide

The Giving Guide helps nonprofits have the opportunity to showcase and differentiate their organizations so that businesses better understand how they can contribute to a nonprofit’s mission and work.

Learn More

Work for ME

Work for ME is a workforce development tool to help Maine’s employers target Maine’s emerging workforce. Work for ME highlights each industry, its impact on Maine’s economy, the jobs available to entry-level workers, the training and education needed to get a career started.

Learn More

Groundbreaking Maine

Whether you’re a developer, financer, architect, or industry enthusiast, Groundbreaking Maine is crafted to be your go-to source for valuable insights in Maine’s real estate and construction community.

Learn more-

The Giving Guide

The Giving Guide helps nonprofits have the opportunity to showcase and differentiate their organizations so that businesses better understand how they can contribute to a nonprofit’s mission and work.

-

Work for ME

Work for ME is a workforce development tool to help Maine’s employers target Maine’s emerging workforce. Work for ME highlights each industry, its impact on Maine’s economy, the jobs available to entry-level workers, the training and education needed to get a career started.

-

Groundbreaking Maine

Whether you’re a developer, financer, architect, or industry enthusiast, Groundbreaking Maine is crafted to be your go-to source for valuable insights in Maine’s real estate and construction community.

ABOUT

NEW ENGLAND BUSINESS MEDIA SITES

No articles left

Get access now

In order to use this feature, we need some information from you. You can also login or register for a free account.

By clicking submit you are agreeing to our cookie usage and Privacy Policy

Already have an account? Login

Already have an account? Login

Want to create an account? Register

Get access now

In order to use this feature, we need some information from you. You can also login or register for a free account.

By clicking submit you are agreeing to our cookie usage and Privacy Policy

Already have an account? Login

Already have an account? Login

Want to create an account? Register

Comments