Wellness Connection of Maine's cannabis business poised for growth

As the legal jangling over Maine's new law allowing retail sales of marijuana continues, and would-be growers snap up commercial real estate around the state, the potentially new business brings with it high startup and ongoing costs.

Take it from Patricia Rosi, CEO of Wellness Connection of Maine, which has been growing and dispensing medical cannabis for half a dozen years. Medical and recreational marijuana is expected to be at least a $20 billion industry nationwide by 2020. In Maine, Rosi estimates it could generate $200 million to $250 million in sales. By comparison, the state's lobster catch was valued at $495 million in 2015. Rosi says her company plans to get into the recreational business when the time is right because it already has the infrastructure and investments. Cannabis is the scientific name for the plant and its products, whereas marijuana, pot and weed are generic words.

But buyer beware is her recommendation to newcomers wishing to get into the recreational business.

“People shouldn't go beyond paying for a warehouse now,” she advises, because of the moratoria in some towns and the clarity that's still needed in the law and how it is implemented.

Then there's the cost to get a building set up to grow cannabis.

“To build this site cost more than $3 million,” she says, adding that came from private investors, as it's difficult for banks and other investors to put up funds considering incompatible federal laws that still render marijuana sales illegal.

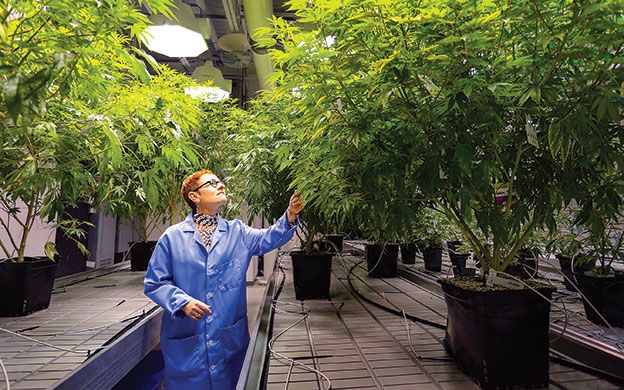

Rosi invited Mainebiz to tour the facility, the first time in five years a reporter and a photographer got such extensive access. For security reasons, she would only say it is in Lewiston/Auburn.

WCM has more than 40,000 square feet of production space, which gives it plenty of room to grow. “One of the biggest expenses after labor is electricity, which is $50,000 per month.” That's $600,000 per year that goes to grow lights, HVAC and equipment.

WCM's 2016 sales were about $15 million, but sales have declined since the recreational marijuana referendum passed. Rosi hopes the company can stay at the $15 million level for this year.

In addition to the factory and a kitchen in Gardiner, WCM owns four of the eight regulated medical marijuana dispensaries in Maine. They're in Bath, Brewer, Gardiner and Portland. The others are Maine Organic Therapy, Ellsworth; Canuvo Inc., Biddeford; Sage Alternatives, Eagle Lake; and Remedy Compassion Center, Auburn.

The Maine Revenue Service reported the $23.6 million in sales at dispensaries generated $1.29 million in sales tax in 2015, up from $16.2 million and $892,000, respectively, in the previous year.

Marijuana, tinctures, topical treatments and other preparations and paraphernalia currently are taxed at 5.5%., according to Maine.gov. Sales of food prepared by a retailer, including “medibles,” are taxed at the 8% prepared food rate and include cookies, butters, oils and bars. The new law would tax recreational marijuana sales at 10%, Rosi says.

“I don't think that's enough,” Rosi says. “I think recreational should be taxed higher so medical patients stay under the medical marijuana program.” The total amount of cannabis that can be cultivated in Maine is 800,000 square feet. There currently are about 37,000 patients using medical marijuana in Maine.

Some 29 states plus the District of Columbia have medical marijuana laws that cover close to 60% of the U.S. population. Colorado has led the charge, bringing in $76 million in cannabis-related taxes compared to $42 million for alcohol taxes in 2014, Rosi told a Jan. 18 meeting of the Kennebec Valley Chamber of Commerce. For each $1 of legally sold cannabis, $3 of economic value enters the American economy, she notes, adding that about 1% of the population in Maine is growing pot.

Better monitoring

The state monitors the dispensaries, but there is no active oversight now for home growers or caregivers of medical marijuana. And while the new law mandates testing and stricter labeling, packaging and advertising of recreational marijuana, Rosi thinks better rules are needed to assure the quality and purity of the product.

WCM has attained ISO 8 cleanroom certification for its extraction laboratory, which means its facilities are almost at the cleanliness level of a hospital, Rosi says. The company has an indoor hydroponic garden.

The factory is divided into two areas, one where the plants are grown, harvested and cured, and a second area where they are processed and packaged. The second area also has a processing area for cannabis parts that will be turned into edibles. In each of the two areas, workers wear the type of bunny suits and shoe covers used in semiconductor factories to keep the area clean from human debris. The growing area uses blue suits and the processing and packaging area uses white suits. Workers going between the two areas have to change so they don't taint the plants or the resulting products.

Even with the state monitoring, Rosi says WCM takes extra steps to assure the fidelity of the strains of marijuana, each of which is targeted for specific ailments like epilepsy, chronic pain or posttraumatic stress disorder. For example, in a self-policing move in the fall of 2015, she says the company voluntarily recalled two strains of medical marijuana that it tested and found had higher than accepted levels of microbes. Those microbes in turn could become moldy if customers store the marijuana in containers with too much heat or humidity. She says there are no state or federal standards for those microbes.

Recently, the company hired a quality assurance and quality control manager, Dan Niesen, who has a PhD in biomedical and pharmaceutical sciences. He says Maine has no mandate to test and regulate marijuana, so WCM is setting up its own lab to look at more of the chemistry.

“In the extraction process, you get fats and waxes from the plants,” Niesen says. “We look to use pure compounds and isolates.”

Currently those test results are strictly for WCM's use, as to print any of the results on its packaging would require use of a third-party laboratory, and current laws don't allow such external laboratories to legally test marijuana, Rosi adds. “We're doing self-imposed safety measures,” she says.

It's not just about smoking

“People think we are a bunch of stoners that smoke just one kind of marijuana and are couch plants,” Rosi says.

Cannabis can be taken in a number of ways, and there are a couple thousand varieties in two large families: indica and sativa, each with their own characteristics. Indica plants are small, stubby and used for pain, sleep and mellowing out, she says. Sativa plants are tall and skinny and activate metabolism and the digestive system in cancer patients, for example. There also are a number of hybrid plants.

Cannabis is taken in five primary methods: smoking, vaporizing inhalation, sublingual (lozenges and tinctures), ingested (edibles) and transdermal (patch or salve). The activation and duration of its effects vary depending on the method and dose. Smoking has a quicker effect but it dissipates faster than eating cannabis, which takes longer to act but lasts longer.

WCM uses both the flower buds that are dried from the plants and an extensive extraction process to use small bud trimmings, leafs that fall off and extracts from fats and waxes, so it uses as much of the plant as possible. The extraction process produces oils and concentrates that are becoming a preferred delivery method, Rosi says, with up to 40% of sales in states like Colorado now composed of concentrates. Such processing allows for more precise dosing, and it doesn't leave odors on clothing, so patients can work without co-workers knowing they are using.

Rosi says companies need more robust procedures to identify if an employee is impaired or not, and many times patients can work fine on the dosage they take.

“People think that because you are using you're abusing,” she says, “which isn't the case.”

There's a general lack of information on marijuana itself and how it works. Drug companies typically study mechanisms of drug delivery and how and why a particular compound works, and whether it is safe, before it is approved by the U.S. Food and Drug Administration for sale. The same is not true with marijuana because of its federal illegal status, Niesen says.

There are more than 2,000 different strains of cannabis, 30 of which WCM processes for medical purposes. Each has different levels of compounds, including tetrahydrocannabinol, also known as THC, which causes the psychological high; cannabidiol, also known as CBD (and there are at least 113 different ones identified in cannabis), which has more of a therapeutic benefit; and tarpenes, which create flavors in medical marijuana that are thought to have a therapeutic effect.

Rosi notes that 85 other chemical compounds can be identified in each cannabis plant. Depending on their concentration in the plant, they can create different effects for patients.

“This is an industry coming from the basement,” says Rosi. “There is no sharing of information or intellectual property.”

She is concerned about the delays to clear procedures for licensing and other issues related to recreational marijuana.

“The problem I have is that the longer they delay the process of recreational marijuana, the more it will enable an explosion in the black market,” she says, adding that there were moratoria initially in Oregon, but the state put in some stopgap measures to squelch black market activity.

Asked about whether she thinks there may be a change in policy at the federal level, she doesn't think the new administration will try to interfere with states that have approved marijuana use.

“[President Donald] Trump is a businessman who likes to make money,” she says. “This is an over $20 billion market by 2020.”

However, she says that with the expected coming changes in Maine with recreational marijuana, it's not clear what regulations will change or remain. “It's like trying to lead a company on quicksand,” Rosi says. “We're trying to do the right thing.

Growing cycle

WCM grows several thousand plants at any given time, only about 6% of what it is allowed to grow legally.

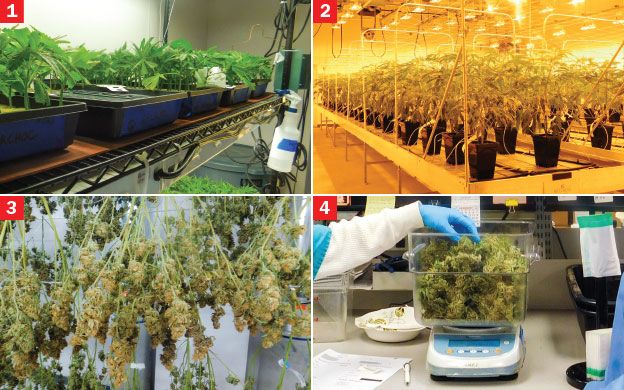

On a recent plant tour, Rosi stood amid a small forest of mother plants, from which clippings are taken. They are planted in rock wool under grow lights for two to three weeks in a nursery, where they develop roots. The plants are known as clones, or copies, at this stage. Each clone is labeled, as the facility produces dozens of different strains of plants.

After the nursery, the plants spend about a month in a vegetative grow room where they are not allowed to flower.

Those plants, which she refers to as “teenagers,” are then taken into a room where the lighting is carefully controlled to stimulate natural conditions outdoors. Half the day they are under grow lights and the other half they are at rest in the dark. At this stage they grow flowers.

The plants are then cut and dried upside down for processing. The plants are put into plastic totes to cure, and after about a week the totes are shaken to “burp” any remaining air out of the soil. Releasing the air assures the humidity is at the correct level. Rosi compares the process to a humidor for cigars.

Once the plant is cured, the flowers are taken out and trimmed, with the extra trimmings and other refuse pulled aside to be processed into edible and other forms.

“We have a fully functioning kitchen in Gardiner with 30 recipes,” she says, including infused honey cookies that don't appeal to children. The facility is aiming to be free from using ingredients with genetically modified organisms.

She says WCM is particularly careful with the edibles it makes, because it doesn't want to have candies that are too enticing to children, for example.

Says Rosi, “We don't have infused Gummy Bears or whoopie pies.”

Comments