FabLab aims to boost Maine manufacturing

Sarah Boisvert wants to stem the tide of young people leaving Maine to find work by transplanting a concept from the Massachusetts Institute of Technology called the FabLab, a facility where students of all ages can use sophisticated equipment to build potential product prototypes.

"Maine needs to capture the middle-class work force," says Boisvert, an entrepreneur who last year left retirement and re-entered the work force to start the FabLab concept in Maine. "The benefits to students include an informal setting for exchange and experimentation, exposure to mentors, creating opportunities for jobs in manufacturing upon graduation for those not interested in college, and developing personal responsibility." Boisvert is an informal volunteer with MIT's Center for Bits and Atoms.

Boisvert's goal is to excite kids about science-technology-engineering-math education. Engine, a community arts organization, recently took over the new Maine FabLab location in Biddeford, which is expected to open in early spring, according to Boisvert. Other locations are possible in the future, but the focus now is to get the Biddeford project up and running as soon as possible.

Separately, she plans to set up a commercial fabrication laboratory, which she hopes to locate at Brunswick Landing, to make tiny micro-manufactured prototypes of products for corporate customers all over the world. That company, to be called MicroFabLab.com, will be a spinoff from the fabrication company she co-founded in Lanham, Md., called Potomac Photonics. She plans to decide on space for that operation this spring, and have the company up and running in the next four to six months with a staff of six to 10 people.

But her initial focus is on the nonprofit labs.

"The beauty is it's open to everyone," she says. "The FabLab fosters innovation across all industries in Maine and can create jobs that will start in the $17-to-$19 per hour range."

The idea for the FabLab originated with Professor Neil Gershenfeld of the MIT Media Lab in Cambridge, Mass. As part of his National Science Foundation funding, Gershenfeld had to devise a community outreach educational component to his project. He developed a course called "how to make (almost) everything," from which the FabLab concept sprung, Boisvert explains.

"There are about 100 FabLabs now worldwide," Boisvert says, "including in Kenya, India, Spain and many U.S. states. Most FabLabs are open to anyone for prototyping."

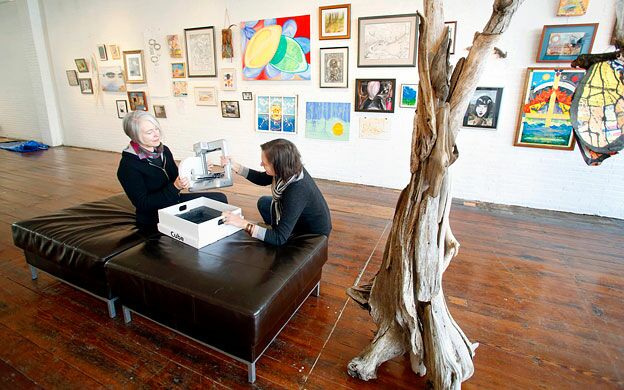

The labs, which cost about $100,000 to set up, have high-tech equipment for vinyl cutting, laser cutting and marking, three-dimensional printing and 3D plotting. The 3D printing is an especially hot topic nowadays, she notes, because such printers hold promise for printing customized items in one piece on demand.

So far, FabLabs in other states have used 3D printers to make a lunch box, fishing lures, architectural models and a custom-fitted hand brace. The printers, which apply laser light to a plastic powder or pellets to create a solid prototype based on a computer-aided design, still print slowly — it can take overnight to print one item — and they can cost several thousand dollars.

Boisvert says the FabLabs have been successful in diverse locations for diverse applications, from students in rural India who developed a tractor to replace a bull that had died to students building microvillage structures for permaculture in Detroit. And in the MC2 STEM High School in Cleveland, the FabLab has been integrated into the curriculum, which led student David Boone, who was once homeless, to use his propensity for tinkering in the lab and eventually get into Harvard University, Boisvert says. She adds that the labs can help students who are better working with their hands or don't learn in conventional ways.

"The FabLab is developing creators, not consumers," she says. "And it's good across subjects. A FabLab can give opportunity to every kid."

One advantage of the FabLab network is that other FabLab locations can share information or expertise, Boisvert explains.

"There is power with the network of FabLabs. An idea in Maine may mesh with work in Australia," she says. "The FabLab is only as limited as the imaginations of the people in it."

Boisvert also is collaborating with Maine Media Workshops in Rockland for a 3D scanning competition. The workshops will host some of the "Bits to Its: 3D Printed Sculpture" exhibition and Maine FabLab's hands-on workshops to try 3D printing and other digital fabrication from April 27-28.

Boisvert plans to raise money for the FabLabs from industry, crowdfunding, grants and selling items made in the labs. Each lab will have an administrative staff. Individual users who are not students will pay a $49 monthly access fee. Full-time students pay only for materials. Corporate users will pay on a sliding scale.

Greg Cavanaugh, program manager at the University of Southern Maine Department of External Programs, is excited about the FabLab concept, and says Boisvert brings expertise, horsepower and connections to Maine.

Cavanaugh adds that there is demand for fabrication work in general in Maine that USM also is tapping. "We have many of the elements that go into making a FabLab at USM, and we provide similar services to the business community here in Maine," he says.

Lori Valigra, a writer based in Harrison, can be reached at editorial@mainebiz.biz.

Editor's note: Some information was updated since this article was first reported. Community organization Engine has taken over the Maine FabLab in Biddeford, which is expected to open in early spring, according to Boisvert, who calls herself an informal volunteer rather than a consultant with MIT's Center for Bits and Atoms. The association with The Community School in New Gloucester will be delayed during the Engine transition. Maine Media Workshops will host some 3D printing workshops during an upcoming art exhibition, but not the entire show.

0 Comments