Processing Your Payment

Please do not leave this page until complete. This can take a few moments.

- News

-

Editions

View Digital Editions

Biweekly Issues

- December 15, 2025

- December 1, 2025

- Nov. 17, 2025

- November 03, 2025

- October 20, 2025

- October 6, 2025

- + More

Special Editions

- Lists

- Viewpoints

-

Our Events

Event Info

Award Honorees

- Calendar

- Biz Marketplace

Report: R&D lags without network

Photo/Courtesy UMS

Hemant Pendse, director of the Forest Bioproducts Research Institute

Photo/Courtesy UMS

Hemant Pendse, director of the Forest Bioproducts Research Institute

Hemant Pendse operates in a nexus of innovation that ties forestry to high-tech industry. His lab developed a way to extract sugars from wood pulp that could be used to create a renewable jet fuel.

It is a type of synergy that Maine leaders say must be adopted everywhere in the state, if grant and investment dollars are to fund a high-tech economy. Money and R&D, those leaders say, is not enough. Maine must find a way to integrate its skills and resources.

“Many, many people know about wood in this state,” Pendse says by telephone from his lab at the University of Maine in Orono. “And we have made great progress in extracting its sugars, which can be used to make bioplastics, biofuels, and, we think, a renewable jet fuel.”

Pendse is chair of the Department of Chemical and Biological Engineering at Orono, and director of the Forest Bioproducts Research Institute, which partnered with Old Town Fuel & Fiber, a company that got a $30 million U.S.

Department of Energy grant to add a bio-products refinery to its mill.

He has proven a wood sugar extract, a slurry called “black liquor,” can be turned into ethanol, butanol and poly-grade lactic acid, a precursor to bioplastics, and is experimenting with turning it into jet fuel. The refinery could be complete within two years.

Pendse is a collaborator with Itaconix LLC, a New Hampshire company that developed a means to use microbes to digest corn glucose into itaconic acid, a granular yellow polymer that is an alternative to petroleum-based poly-acrylic acids, the polymers used in laundry detergent, diapers, cosmetics, inks, cleaners and house paint. Such partnerships between the innovators and the investors must grow if Maine is to find a toehold in an R&D-based economy, he says.

Commercialization is key

Ten years ago, sweeping policy changes and funding channels for high-tech research and development were instituted, but many of the channels remain unfunded by the state, and R&D spending is now declining.

According to the National Science Foundation, through all public and private channels, $148 million was spent on R&D in Maine in 1997, $524 million in 2005 and $450 million in 2007, accounting for about 1% of the gross domestic product in the state.

In 2008, only $18 million in venture capital was spent in R&D — an amount that is typically invested in Boston-based companies in a single hour, according to data from the National Venture Capital Association.

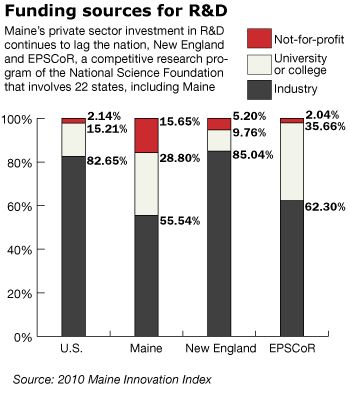

In fact, the state’s private sector R&D spending measures only 55.5% of the state’s total, while the rest of New England sees about 85%, according to the 2010 Maine Innovation Index. Catherine Renault, director for the Maine Office of Innovation and an architect of the innovation index, is one of the authors of a new policy paper, called the 2010 Science and Technology Action Plan, which lays out new strategies and goals intended to create more working synergies among companies.

She sees a “commercialization gap,” and says what has essentially been missing is not just money — Maine has boosted its R&D spending in the past decade — but adequate connections among companies, universities and investors, to bring ongoing R&D to market and create a critical mass of activity.

Maine, she says, suffers from a business climate that is essentially Balkanized, made up mostly of companies with fewer than 10 employees, which have been largely unable to take ideas to market. But by joining forces, a new economy will begin to materialize, she says; in effect, the cooperative value of skills and resources already in the state that are not yet realized, nor visible.

“It used to be all these companies were in different silos,” she says. “Now it’s coming together, and that’s true for the IT sectors, and for offshore wind — if you put deep water wind turbines out in the middle of the Gulf, you need environmental folks, engineers and technicians, and composite manufacturers.”

Those collaborative, high-tech relationships are what Renault calls the new “innovation economy.”

In the Science and Technology Action Plan, the authors lay out an aggressive set of goals, including driving R&D spending from $450 million a year, or 1% GDP, to $1.4 billion a year by 2015, a figure that would account for 3% of Maine’s GDP. The New England average is 4.9%.

Virtually all of the state funding for R&D comes from the state’s General Fund and is channeled through two entities: the University of Maine System, which captured $17,375,000 in the 2008-09 fiscal year; and the Maine Technology Institute, which captured $8,467,977 the same year, according to the index.

Renault says upping R&D spending to $1.4 billion can happen by increasing the state’s contribution marginally to $30 million and drawing the interest of larger companies and their integrated connections. Interdisciplinary research projects will trigger additional private sector investment, she says.

That includes projects such as Pendse’s jet fuel collaboration with Old Town Fuel & Fiber and another project, headed by Michael Belliveau, executive director of the Environmental Health Strategy Center, which explores turning potatoes into bioplastics. That project, which has $2 million in backing, has drawn investment interest from Tom’s of Maine Inc., Rynel Inc. and True Textiles Inc.

Renault and others expect that R&D-fueled growth is apt to gain the most traction from the energy industry. It will rely on companies such as Ocean Renewable Power Co., which put a 60-kilowatt pilot commercial tidal turbine system into the ocean at Eastport earlier this month. Chris Sauer, CEO of Ocean Renewable, says he has plans to install 100 megawatts of equipment at Eastport within five years, and has the network in Maine to do it.

Among those who helped install the pilot project in Eastport were US Windblade Inc. of Bath, which usually makes composites for racing yachts, Morrison Manufacturing Inc. of Perry and Alexander’s Welding and Machine Inc. of Greenfield, which fabricated the barge and deployment system for the system.

“I was really surprised at how much collaboration we were able to find in Maine,” Sauer says. “We looked for top-notch experts, and for the most part, we found them.”

Mainebiz web partners

The Giving Guide

The Giving Guide helps nonprofits have the opportunity to showcase and differentiate their organizations so that businesses better understand how they can contribute to a nonprofit’s mission and work.

Learn More

Work for ME

Work for ME is a workforce development tool to help Maine’s employers target Maine’s emerging workforce. Work for ME highlights each industry, its impact on Maine’s economy, the jobs available to entry-level workers, the training and education needed to get a career started.

Learn More

Groundbreaking Maine

Whether you’re a developer, financer, architect, or industry enthusiast, Groundbreaking Maine is crafted to be your go-to source for valuable insights in Maine’s real estate and construction community.

Learn more-

The Giving Guide

The Giving Guide helps nonprofits have the opportunity to showcase and differentiate their organizations so that businesses better understand how they can contribute to a nonprofit’s mission and work.

-

Work for ME

Work for ME is a workforce development tool to help Maine’s employers target Maine’s emerging workforce. Work for ME highlights each industry, its impact on Maine’s economy, the jobs available to entry-level workers, the training and education needed to get a career started.

-

Groundbreaking Maine

Whether you’re a developer, financer, architect, or industry enthusiast, Groundbreaking Maine is crafted to be your go-to source for valuable insights in Maine’s real estate and construction community.

ABOUT

NEW ENGLAND BUSINESS MEDIA SITES

No articles left

Get access now

In order to use this feature, we need some information from you. You can also login or register for a free account.

By clicking submit you are agreeing to our cookie usage and Privacy Policy

Already have an account? Login

Already have an account? Login

Want to create an account? Register

Get access now

In order to use this feature, we need some information from you. You can also login or register for a free account.

By clicking submit you are agreeing to our cookie usage and Privacy Policy

Already have an account? Login

Already have an account? Login

Want to create an account? Register

Comments