Sappi to invest $418 million to upgrade Skowhegan paper mill

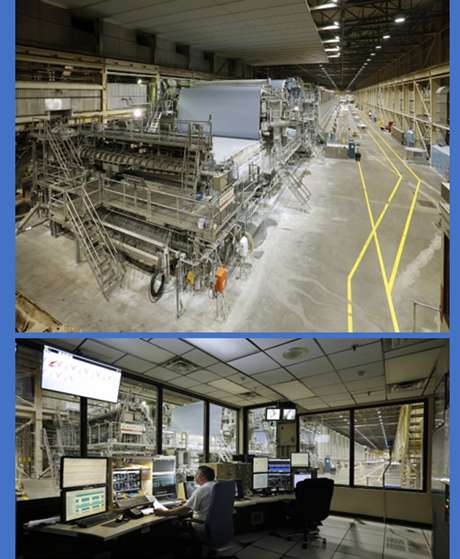

Courtesy / Sappi North America

Sappi North America it will invest $418 million in a paper machine rebuild at its Somerset Mill in Skowhegan.

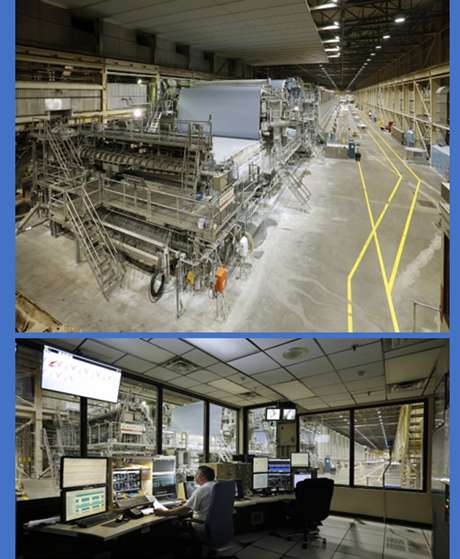

Courtesy / Sappi North America

Sappi North America it will invest $418 million in a paper machine rebuild at its Somerset Mill in Skowhegan.

Sappi North America said Thursday it will invest $418 million in a paper machine rebuild at its Somerset Mill in Skowhegan.

The paper manufacturer said the investment will further its mission of sustainability, increasing Paper Machine No. 2’s capacity to produce solid bleached sulfate board products, a sustainable alternative to plastic packaging.

The effort will reduce the use of plastics within health, beauty and food services industries, among others. In 2017, Sappi invested $165 million to upgrade Paper Machine No. 1, which gave the machine greater flexibility in the production of paper-based packaging products.

The latest round of upgrades will be funded from free cash flow, the company said. Upgrades on Paper Machine No. 2 will be completed by early 2025.

“This move complements our long-term Thrive25 strategy, which focuses on growing our portfolio in packaging and specialty papers, pulp and biomaterials,” said Mike Haws, president and CEO of Sappi North America. “By investing in our business to pursue growing areas of demand, we can remain profitable and competitive in the global marketplace”

Sappi, a South African company with a U.S. headquarters in Boston, has manufacturing operations on three continents in seven countries, with 12,000 employees, including 750 at the Somerset Mill.

'Robust' demand

Demand for packaging and specialty papers in North America is particularly robust, the company said, "especially since [solid bleached sulfate] products are a more environmentally sustainable alternative to plastic packaging, and customers are actively seeking to increase their volumes with Sappi North America."

The packaging is used for cosmetics and perfume, health and beauty care, consumer electronics, confectionary, luxury drinks and more. Foodservice items such as plates, dishes and cups also use SBS as a sustainable alternative to plastic.

“Somerset’s existing world-class infrastructure and success in producing high quality SBS products, together with its talented workforce, make the mill an excellent and obvious choice for this investment,” said Haws. “Increasing our flexibility and expanding the paper mill’s capability and capacity will ensure that we continue to make superior products at Somerset for years to come.”

0 Comments