Lewiston-based Elmet Technologies turns to German manufacturer for space-age metals

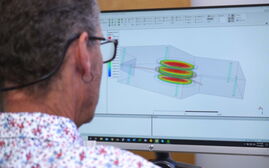

Photo / Courtesy Elmet Technologies LLC

Elmet Technologies in Lewiston signed an agreement with a German producer of two metal materials that work particularly well in aerospace and space exploration.

Photo / Courtesy Elmet Technologies LLC

Elmet Technologies in Lewiston signed an agreement with a German producer of two metal materials that work particularly well in aerospace and space exploration.

Elmet Technologies LLC, a tungsten manufacturer in Lewiston, signed a strategic agreement with a German producer of two metal materials that work particularly well in aerospace and space exploration.

Taniobis GmbH, a subsidiary of JX Metals Corp. and headquartered in Goslar, Germany, produces tantalum and niobium materials and related tantalum and niobium based alloys.

The agreement is expected to strengthen the supply chain for the materials in the U.S. and elsewhere in North America for critical high-performance applications, according to a news release.

Terms of the deal were not disclosed.

The partnership will unlock “a more comprehensive material, product and service portfolio for our customers,” said Scott Knoll, Elmet’s executive vice president of strategy:

For Taniobis, Elmet is considered an ideal partner to deliver customer and application support to the U.S. aerospace and defense industries, said Ole Brettschneider, Taniobis’s chief commercial officer.

Niobium and tantalum are closely associated elements discovered in 1801 and 1802, respectively.

Moon shots

Established in 1929, Elmet is part of Anania & Associates Investment Co. LLC, a Maine-based holding company that focuses on manufacturing. customers and applications include defense, aerospace, medical, semiconductor and industrial furnace.

Elmet has occupied the same location, on Lisbon Street in Lewiston, from the start. In 2023, it acquired H.C. Starck Solutions Americas and Starck’s manufacturing facilities in Coldwater, Mich., and Euclid, Ohio, thus becoming the largest U.S.-owned producer of tungsten and molybdenum materials and products, with nearly 400 employees across three facilities totaling over 500,000 square feet in Maine, Ohio and Michigan.

Examples of its production are heatshield components for a NASA space launch system and components for Dragonfly, a NASA mission scheduled to launch in 2026 and land on Saturn's largest moon, Titan, in 2034.

Taniobis was formerly part of H.C. Starck but was acquired by JX Metals and Mining Corp. in 2018 and rebranded as Taniobis in 2020.

High strength, high temp

Although Elmet already produces components for NASA and other high-performance applications using molybdenum, tungsten and related alloys, niobium and tantalum are better materials for different applications, depending on factors involved in the application and its environment, Kevin Smith, Elmet’s director of marketing, told Mainebiz.

“Material characteristics like strength, density, ductility, melting point, thermal conductivity, corrosion resistance and more influence which materials perform best in certain applications,” he said.

For aerospace and space exploration, a key advantage of niobium is its high strength at high temperatures, he said.

As experts in manufacturing molybdenum and tungsten, Elmet will leverage its existing manufacturing techniques, infrastructure and powder metallurgy expertise to deliver a portfolio of high-performance products and materials that will now include powders consisting of niobium and tantalum in pure and alloyed forms.

Taniobis alloys are already in use at Elmet’s Coldwater, Mich., facility.

The Lewiston plant will continue to produce a range of pure molybdenum, tungsten and related alloy products.

Niobium exhibits unique properties such as high temperature stability, superconductivity, high ductility and biocompatibility. Niobium powders are widely used in aerospace, medical, nuclear, energy and automotive industries.

Tantalum exhibits outstanding properties such as high strength, high ductility, excellent corrosion resistance and biocompatibility providing unique possibilities for application in aerospace, medical, nuclear and chemical industries.

Last year, Elmet agreed to a collaboration with Australian tungsten supplier EQ Resources Ltd. (ASX:EQR) to strengthen the Western industrial base and supply chain for the metal.

Having a mostly North American customer base and a Western supply chain, Elmet has experienced limited impacts from federal trade tariffs, said Smith.

0 Comments