After $125 million retrofit, TimberHP's Madison mill will produce high-performance insulation

Rendering / Courtesy of TIMBERhp

TimberHP is retrofitting the Madison mill and expects to roll out the first of three product lines in April.

Rendering / Courtesy of TIMBERhp

TimberHP is retrofitting the Madison mill and expects to roll out the first of three product lines in April.

After several years of planning and preparation, a defunct paper mill in Madison has come roaring back to life with a new product: high-performance wood fiber insulation for homes and other buildings.

TimberHP, the mill’s new owner, expected to roll out the first of three planned product lines (loose fill, batt and board) in April, with the other two products launching before the end of the year. While wood fiber insulation is popular in Europe, TimberHP will be the first company to produce it in the United States.

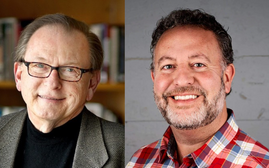

“It’s a different type of insulation than anyone has seen in America,” said company co-founder and CEO Joshua Henry, adding that retailers and distributors have expressed strong interest. “They’re quite eager to get their hands on that product.”

TimberHP is the brainchild of Henry, a trained chemist, and business partner Matthew O’Malia, an architect. Conceived in 2015, the company had 36 employees as of February, with plans to grow its staff to 60 by the end of 2023 and 140 within the next three years.

The project gained momentum in 2017 when Henry and O’Malia were able to source the needed production equipment at a steep discount from German company Homanit Building Materials. With a deal set for the equipment, they bought the mill property in Madison, about 60 miles west of Bangor, for $1.4 million in 2019.

But the startup hit a snag in 2020 when travel to Europe was suspended by the pandemic, cutting off access to a key potential investor. With limited time to capitalize on available tax credits, Henry and O’Malia pivoted to working with the Finance Authority of Maine, or FAME, on a public-private funding package that included $85 million in tax-exempt conduit bond financing.

Other state, regional and local entities jumped on board, as did private investors. In all, TimberHP has managed to secure more than $125 million in loans, grants and private equity investment. About 60 percent of the company’s private investors are in Maine, Henry said.

Participating groups on the public side include the Maine Rural Development Authority, town of Madison, state Department of Economic and Community Development, Somerset Economic Development Corp., Coastal Enterprises Inc., Eastern Maine Development Corp. and Maine Technology Institute.

Maine economic development officials see multiple benefits to backing TimberHP, said Carlos Mello, FAME’s CEO. Not only is the venture bringing back lost jobs to an economically depressed community, but it also has created a new use for timber industry byproducts that might otherwise be disposed of as waste.

“From an economic development perspective, this checks off all the boxes,” Mello said. “It increases employment, and [they’re] good quality jobs. It creates a product that is green and helps with carbon-neutrality, and it helps regenerate and create a use for product that has been impacted due to the decline of pulp and paper manufacturing in the state.”

Smart course of action

It’s not unusual for Maine businesses to turn to economic development groups for financial help, Mello said, but the TimberHP financing deal is one of the largest FAME has ever participated in. In more typical cases, the quasi-independent state agency provides more modest financing as a means to help spur private investment.

Other businesses FAME has worked with recently include Portland-based “biochar” maker Standard Biocarbon, tissue paper manufacturer St. Croix Tissue in Baileyville, eel farm American Unagi in Waldoboro, Saddleback Mountain ski resort in Rangeley and mixed-use development Rock Row in Westbrook.

TimberHP products are not only made of renewable material, Henry said, but their cost and performance are comparable to leading insulation products such as foam, rockwool and fiberglass. (The “HP” in “TimberHP” stands for “high performance.”) And despite being mostly wood fiber, TimberHP products also meet comparable standards for fire resistance.

The product launch comes at a time when borrowing costs are on the rise and housing starts are expected to decline. Still, the company expects to do well because its products will be desirable for renovation jobs as well as new construction. Henry and O’Malia are already thinking about expansion and have been eyeing the Pacific Northwest as a possible target.

But for now, the focus is on Madison. Henry said he is grateful to the local, county and state officials who worked diligently to help the financing come together. TimberHP is planning a community barbecue in Madison on July 21 to celebrate its grand opening and welcome the public.

“I think Maine’s true advantage when it comes to doing something like this is that we don’t have all the financial power that bigger and more economically robust states have, but we have each other,” Henry said.

0 Comments