Blacksmith and specialty knife retailer team up to 'forge' a Portland startup

Photo / Courtesy Softcut Knife Co.

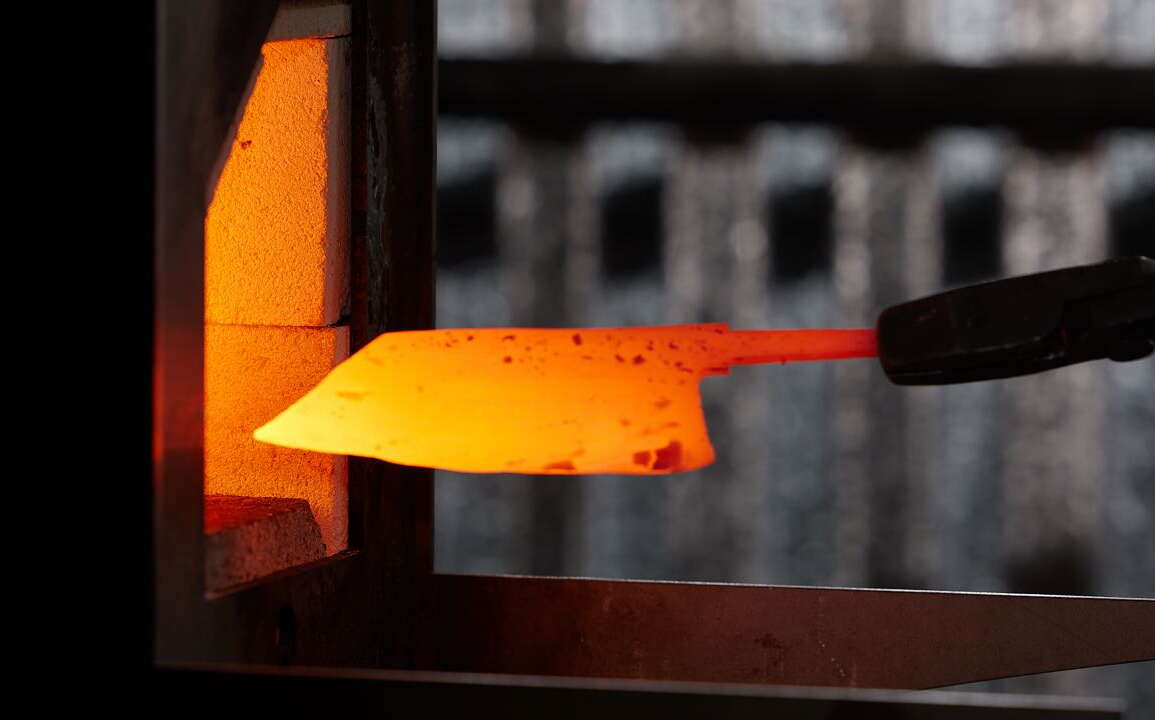

The line uses a type of high-carbon steel

Photo / Courtesy Softcut Knife Co.

The line uses a type of high-carbon steel

A blacksmith and a specialty knife retailer joined forces to launch a Portland business that makes and sells hand-forged knives designed and crafted in small batches.

Kiran Chapman of Soma Metalwork and Evan Atwell of Strata and Strata Swords said Softcut Knife Co. specializes in Japanese-inspired blades.

“For years, Evan and I have each honed our own relationships to the knife world from different angles — myself from teaching and spending time in the forge, and Evan from honing sharpening and polishing techniques, as well as establishing roots in the global knife industry,” said Chapman. “Softcut is where those two realities merge and inform one another.”

Blacksmith and cutlery

Chapman is a blacksmith who started Soma Metalwork to forge kitchenware and home goods.

Originally from New York City and after a career in design and public relations, he moved to Maine in 2018 to pursue wooden boatbuilding, then knife-making and blacksmithing.

In 2022, Chapman started Soma Metalwork in North Yarmouth and also began managing the sharpening department at Strata, where exposure to a wide range of blades pushed him to dive deep into metallurgy and knife geometry.

Atwell started Strata in 2019 at 93 Washington Ave., a retail incubator known as the Black Box.

He got interested in the subject of specialty knives while working in retail in San Francisco, near a cutlery store.

“I got interested in that subject, spending lunch breaks going over there and asking questions,” he said.

Moving to Portland, he spent time working at Rosemont Market and Bakery, getting to know the Portland food industry and soon offering knife-sharpening services. After four or five months, he had enough traction from drop-offs to open Strata as a sharpening service and culinary knife and kitchenware shop

“It was very busy right off the bat,” he said.

He reinvested every penny into acquiring more products. Knives from Japanese makers are especially difficult to obtain these days, he said. But at the time, he established relationships with as many makers as possible. After a year or two, he outgrew the Black Box space and moved a third of a mile to 67 Washington Ave.

This year, Chapman and Atwell leased space and built a dual workshop at 1 Industrial Way in Portland, both for Soma as a blacksmith studio and for holding knife-making and blacksmithing classes, as well as for Softcut's forging and sharpening space.

Japan-inspired

Chapman stopped by Strata about six years ago.

“I had just started forging that year,” Chapman said. “As I started to pursue that world, knowing that ecosystem of knives and chefs and makers made me optimistic about doing this work.”

Chapman became a sharpener at Strata.

“He and I have built a strong relationship,” said Atwell.

Their respective fields placed them in collaboration with Japanese makers and workshops, shaping their understanding of geometry, steel behavior, history and real-world kitchen needs.

The two traveled to Japan together last October and plan to go again this February to study the craft.

Combined expertise

Wanting to combine their respective expertise in the knife industry to make Japanese-inspired blades, they started Softcut Knife Co., bringing together Chapman’s metalworking and blade-smithing experience with Atwell’s sharpening expertise and direct relationships with knife producers around the world.

Softcut’s debut collection features five core blades, some in carbon and some in stainless steel, that Chapman and Atwell spent the last two years prototyping, testing and refining.

“Our goal is straightforward,” said Atwell. “Make knives that perform beautifully and are informed by years of selling and servicing many exceptional blades. We expect a wide range of users, from home chefs to industry professionals, and we’ve designed knives to hit the mark for both.”

Hybrid design

The knives are forged, heat-treated, ground and finished by hand at the 1 Industrial Way workshop. The design is Japanese-inspired with Western influences. The first line to launch is a hybrid with Japanese-style handles and profiles but Western blade construction, which consists of forging a single piece of steel, as opposed to the generally Japanese method of laminated construction. The techniques differ in factors such as hardness, brittleness, stiffness and shape of the blade and the handle. One method is not better than the other, Atwell added.

“It’s relative to the user and what they’re doing,” he said.

Global clicks

The Softcut website and the first batch of blades went live earlier this month. The partners are selling the product at Strata and online.

Further plans include importing specialty machinery and tools from Japan, including a custom belt grinder that’s expected to arrive in the coming months.

“We’ll have some custom-built specialized machinery that’s not available in the west,” said Atwell.

Financing for the startup piggybacks on both preexisting businesses. Chapman estimates he’s spent $30,000 to $40,000 to outfit his Soma workshop, the majority of which will be used for Softcut. Additional machinery, tools and website could be another $30,000. They’re working with Zack Bowen of Maine Studio Works in Portland to market the business, which the partners are self-funding.

Over the last month, Chapman has turned out 20 to 30 knives, which are selling out. He’ll continually add to the inventory. Softcut’s website has been getting clicks from all over the world.

“I’m packing up some right now that are going to go to California,” Chapman said.

He added, “Now comes the focus on growing the brand, growing the business, figuring out the marketing and all the stuff that doesn’t involves being a craftsman but is necessary.”

0 Comments