David Harbison Jr. tells the story of Bison Pumps of Houlton

Photo / Lori Valigra

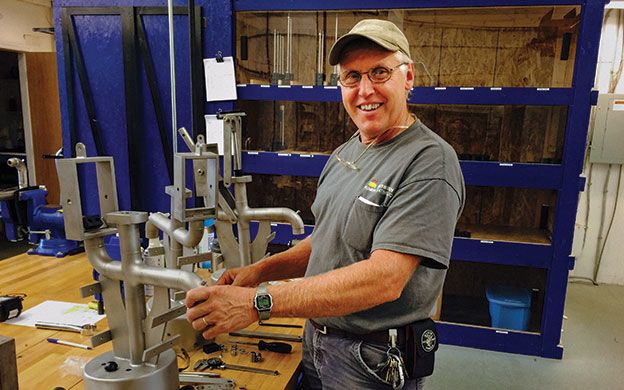

David Harbison Jr., president of Bison Pumps in Houlton, says water pumps like the one pictured provide an alternative when the electricity goes out.

Photo / Lori Valigra

David Harbison Jr., president of Bison Pumps in Houlton, says water pumps like the one pictured provide an alternative when the electricity goes out.

David Harbison Jr. remembers the crippling ice storm of January 1998 like it was yesterday, but for another reason. It spawned his current company, Bison Pumps of Houlton.

While servicing heating systems for the family plumbing business, Harbison, Plumbing, Heating & Air Conditioning, several customers asked for old-fashioned hand pumps they could mount atop their drilled rural wells, which had been idled by the widespread electrical blackout.

The company didn't sell them, but Harbison and a colleague decided to build a hand pump. They started selling it the following year as part of Harbison Plumbing, but it became so popular that Bison Pumps was set up as a separate company in 2006. Sales were primarily through the Internet — and still are — to home and professional customers. The company also sells through 260 dealers who are licensed plumbers, well drillers or pump installers.

Harbison says homeowners can install the pumps by themselves and, even in the worst storm situations or when their backup generator fails, they'll still have water, an essential item during an emergency. The company sells 16 different models running from $500 to $5,000. It recently launched a new line of commercial pumps that can put out 15 gallons per minute, three times the amount of Bison's typical pumps.

The company now has 11 full-time employees. Maine is its top state for sales, followed by New York, Pennsylvania and Florida. It also has two dealers in Australia, one in Japan and several in Canada. Because it's always winter somewhere, his company is barely able to keep up with orders.

Harbison recently sat down with Mainebiz in his 6,000-square-foot space just outside downtown Houlton, talking about how he may need to expand and hire if business continues at its current pace. An edited transcript follows.

Mainebiz: You're selling a product people associate with the settlers. How do you explain what you do?

David Harbison Jr.: The most frequent question I hear is 'Why the hell would I buy a hand pump?' Anybody with a private water system can use them. I talked to an Ohio plumbing contractor who went through a storm, then bought a $10,000 whole house backup generator. Then there was another big storm and it failed. He bought a simple pump so he could pump water. Everyone needs water.

MB: How does it work?

DH: It comes as a kit that we ship and customers can install it on top of their outdoor pump. They take off the bolts that hold on the well cap, insert a cylinder for pumping and eight-foot segments of PVC pipe until the pump reaches the water. They can pump water into a bucket and take it into the house. Some people put the pump next to their kitchen sink. Our stainless steel pump designs are a new twist on an old technology. Old pumps typically were made of iron that could rust. Water quality is a big concern.

MB: How did you fund the company?

DH: We initially used the plumbing company's resources, but we are profitable and self-funded now.

MB: Do you also make custom pumps for other uses?

DH: We make a kegerator novelty pump for beer, for $2,200. Beer pumps could be a big market that we may look at. We also make special pumps for playgrounds that can tap into city water. They are for educational activities, so kids can learn about water conservation, planting gardens and self-sustainability. The new 15-gallon model is for small farms and overseas for community pumps, for example in places like Haiti.

MB: You use state-of-the-art computerized numerical control (CNC) machines. Why?

DH: We have three CNC machines that we use to make all of our small parts and drill out fine areas. We've hired the people who run the machines from Northern Maine Community College, which has a precision machining technology program. I think such high-end trade work could keep young people in the community.

Comments