TechPlace startup to advance biomedical product development through Roux residency

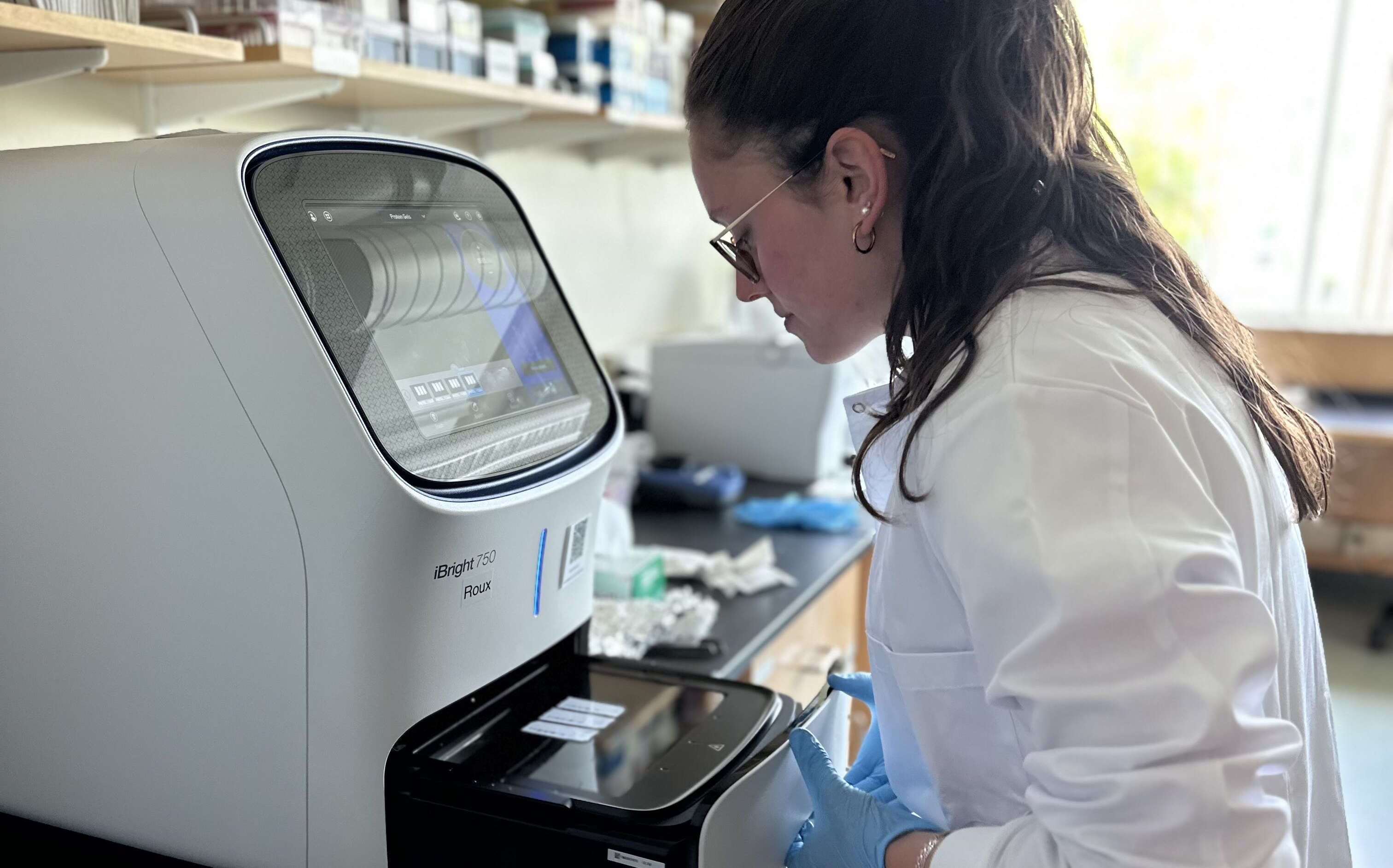

Photo / Courtesy Salmonics LLC

Cem Giray, CEO and president of Salmonics LLC, said a 12-month residency at the Roux Institute will help the startup refine its technology and enhance development of its fish-derived biomedical products.

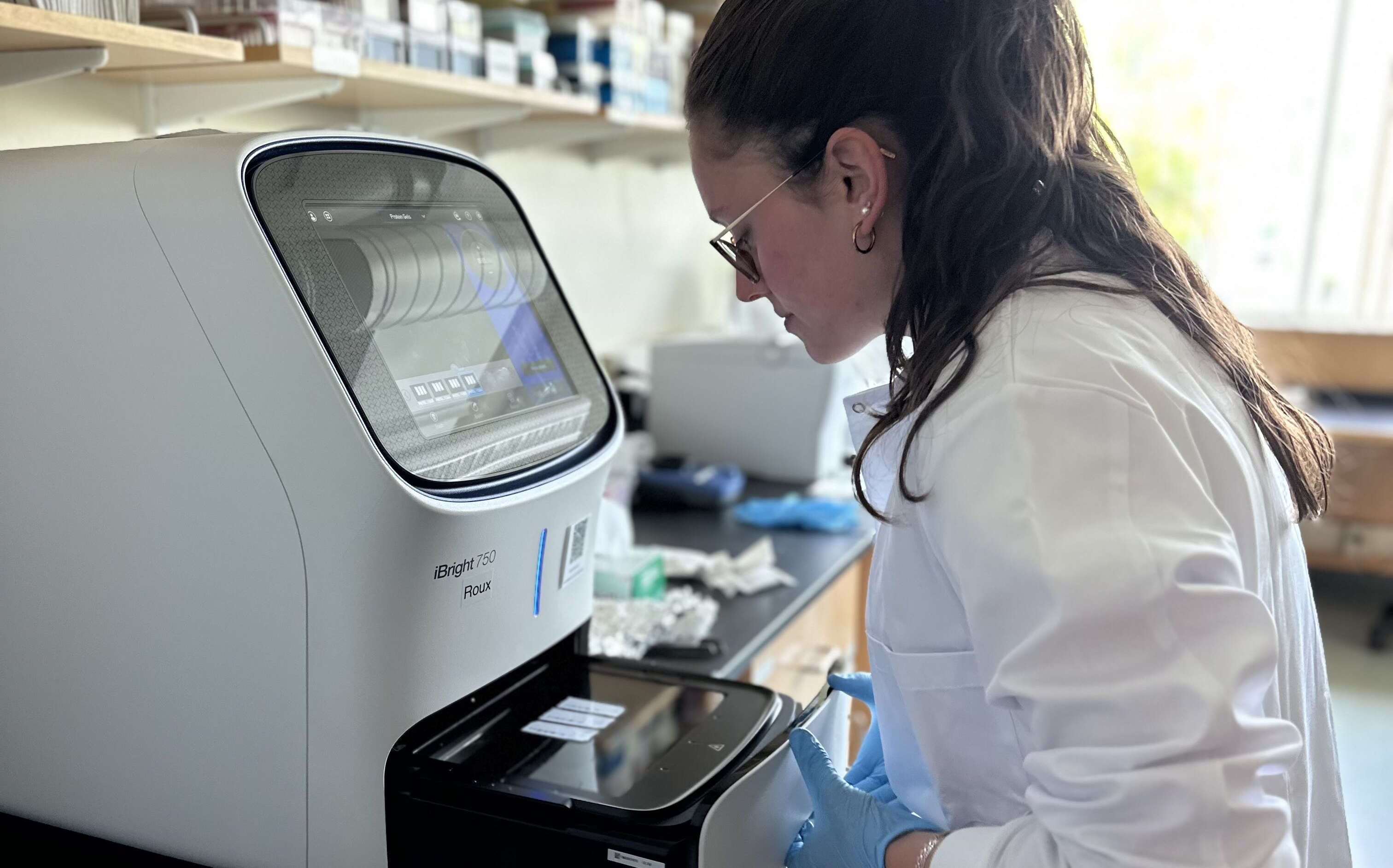

Photo / Courtesy Salmonics LLC

Cem Giray, CEO and president of Salmonics LLC, said a 12-month residency at the Roux Institute will help the startup refine its technology and enhance development of its fish-derived biomedical products.

Salmonics, a biotech startup at TechPlace in Brunswick, is taking part in a 12-month residency at Northeastern University’s Roux Institute in Portland with a goal to refine its technology and enhance development of its fish-derived biomedical products.

Salmonics is an inaugural member of the BioPILOT Lab, which supports Maine-based biotech companies by offering access to shared lab space and equipment for research in cell biology, microbiology, biochemistry and molecular biology.

“Membership in the BioPILOT Lab marks an exciting milestone for Salmonics as we expand our research and product development capabilities and continue bringing novel, sustainable solutions to laboratories,” said Cem Giray, Salmonics’ founder, CEO and president.

Founded in 2020, Salmonics turns fish-derived plasma proteins that would otherwise be discarded as waste into biomedical products for research, diagnostic purposes, wound healing, pain management and trauma care in human and veterinary medicine.

The company’s foundation stems from the work of Sea Run Holdings Inc., established in 1981 by Evelyn Sawyer with the discovery of therapeutic properties of salmon plasma proteins, including pain relief, according to a news release.

The residency is funded through the Maine Technology Institute.

Seafood waste

According to a recent report by the World Economic Forum, seafood waste totaled 23.8 million tons in 2021, Giray told Mainebiz.

“By extracting serum and plasma from fish already destined for dinner plates, we are reducing the amount of byproduct waste entering the environment and creating a value-add to the harvested fish,” he said. “In addition to our big picture mission, Salmonics also supports sustainable practices through sourcing through sustainable certified fisheries, using recyclable packaging and implementing energy efficiency in our facility.”

Salmonics partners with aquaculture companies that provide raw material and fish blood and “are an essential part of our business,” said Giray. “While we are providing high-quality product to our customers, we are at same time providing high-value add to our aquaculture and fisheries partners for a byproduct that would otherwise join the waste stream.”

The BioPilot program gives the company access to equipment such as mass spectrometers and protein analyzers, as well as to expertise and training.

“This access enables us to test and refine our products,” he said.

The company is focusing on refining its “blocker” product, which is used to detect pathogens or antibodies and to better understand how cells work or how diseases develop.

It will also soon begin field testing for U.S. Food and Drug Administration listing of its veterinary surgical product that promotes blood clotting and helps with wound care.

Build living tissues

The company is working toward raising $2 million to expand sales and marketing capabilities, and to validate and launch a veterinary product that has potential for human clinical applications.

“We continue to move forward with fundraising options,” said Giray.

Customers include researchers and diagnostic companies.

“An emerging area of interest is 3D bioprinting, where our products are used in advanced 3D printing techniques to build living tissues and organ-like structures by layering cells and biomaterials,” said Giray. “These materials support research in areas such as tissue engineering, regenerative medicine and cancer research, where more physiologically relevant models are essential for accurate results.”

The company has six employees and eight contractors, rents 2,400 square feet of laboratory, manufacturing and storage space at TechPlace and is exploring new product development opportunities.

“The addition of the Roux Institute partnership has expanded our access to specialized expertise and advanced instrumentation, which is helping accelerate our innovation efforts,” said Giray.

0 Comments