As Maine forest products initiative advances, workforce shortage remains an issue

Coutesy / FORMaine video screen image

The Forest Opportunity Roadmap/Maine initiative, which aims to grow the state's forest industry by 30% by 2025, is holding its 2021 Summit Friday to assess progress.

Coutesy / FORMaine video screen image

The Forest Opportunity Roadmap/Maine initiative, which aims to grow the state's forest industry by 30% by 2025, is holding its 2021 Summit Friday to assess progress.

The issue for Maine's forest product industry after a year of a pandemic economy is one it faced before the pandemic — finding the workforce to cut down, haul and manage the timber and the products it produces.

When Forest Opportunity Roadmap/Maine, a coaltion of industry stakeholders, was formed in 2018, the focus was on adding 30% growth to the industry by 2025. The virtual 2021 Maine Forest Bioeconomy Summit, to be held Friday, will assess the progress at the initiative's halfway point, but the workforce issues are clear, said Patrick Strauch, executive director of the Maine Forest Products Council.

FOR/Maine partners are the council, the University of Maine, Professional Logging Contractors of Maine, Maine Development Foundation, Maine Woodland Owners and Biobased Maine.

Strauch said the workforce issue continues at a time when more bio-economy leaders are looking at Maine for both traditional industry products and more innovative ones.

"They're kicking the tires and looking at Maine," he said.

"There's a shortage of truck drivers, there's a shortage of loggers," Strauch said. The pandemic has caused major timber supply chain issues, adding to imbalance.

Demand is way up and prices are fluctuating. But the pandemic is an anomaly. "Prior to COVID we were still having trouble hauling wood to market," he said.

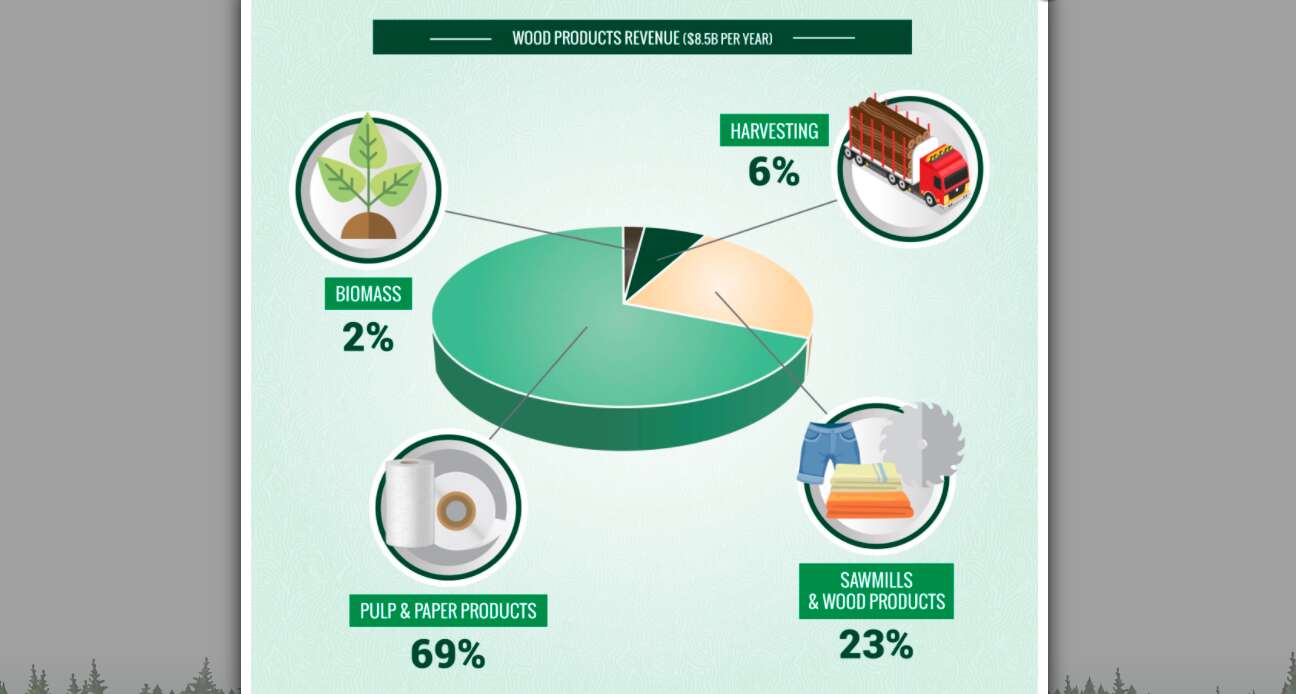

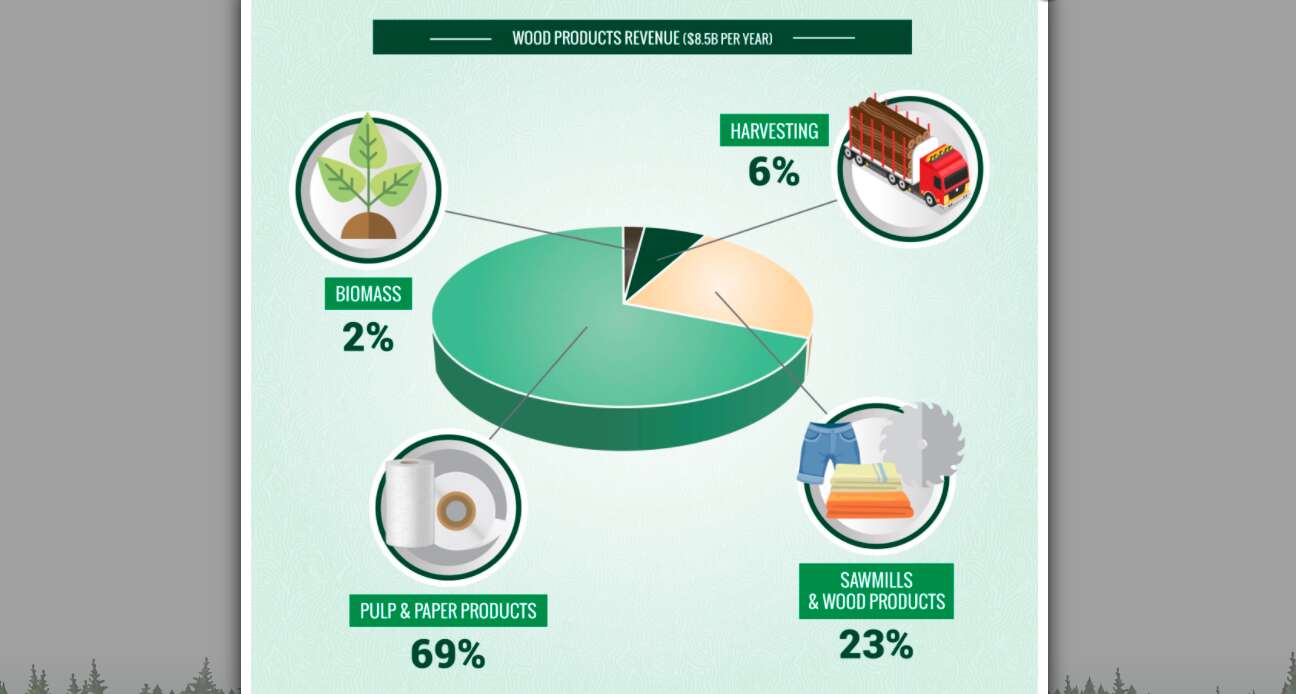

The aim of the FOR/Maine initiative, which began two years before the pandemic, is to set the market up to weather economic ups and downs, and build an industry and workforce that takes advantage of Maine's rich forests. It addresses both the traditional papermaking and log-sawing sectors, which are 92% of the state's $8.5 billion timber industry, as well as innovative ways to use timber.

In recent years before than pandemic, there was also $1 billion investment, mostly in emerging products. The industry can grow with products like the wood fiber insulation that will soon be produced by GO Lab at the former Madison paper mill; cross-laminated timber, like that which will be produced by Ligna Terra at the Lincoln Forest Industry Park on the site of that town's former paper mill; nanocellulose (a "plastic" made from wood fiber), and more.

Last June, the FOR/Maine initiative and Maine Development Foundation awarded $1 million in grants to five mill towns in Somerset, Penobscot and Aroostook counties to attract capital investment and boost the economy after mill shutdowns.

Strauch said it's all part of the bigger effort to boost the state's forest industry, and aligning needs of the traditional and emerging markets and how they can be filled tied with the new investment.

Attracting investment, targeting resources

The strategies for the first phase of the FOR/Maine project were to attract new investment, marketing and promotion, and to develop new products from residual materials of traditional wood-manufacturing processes. That phase included a global market analysis focused on identifying opportunities for expansion of Maine’s forest economy based on nailing down wood availability, global market dynamics and existing operators.

One study during the phase found that Maine’s abundance of spruce, fir and wood residuals provide opportunities for growth, and there is a a significant amount of wood resource on parcels controlled by small landowners. Those residuals can be used for new products,

Phase II, which began in December 2019, made the shift to industry growth, including educating small landowners about options for land management; identifying and amplifying emerging technology; and tackling workforce issues.

Strauch said that disruption in the market because of the pandemic, as well as the pulp digester explosion a year ago at the Pixelle Specialty Solutions mill in Jay, have thrown some curveballs at the effort. Friday's summit will assess where things stand and where they need to go to make the industry strong in the coming decades.

Stakeholders involved in the FOR/Maine initiative besides the Forest Products Council of Maine include Maine & Co., the Maine International Trade Center, the University of Maine, the Maine Department of Economic and Community Development and Biobased Maine.

The timber industry, without the disruption of the pandemic, generates revenue of $8.5 billion a year. "The goal is to get back to being a $12 billion industry," Strauch said.

Workforce shortage remains a challenge

A presentation by Friday by Ryan Wallace. director, Maine Center for Business and Economic Research at Muskie School of Public Service will take a look at workforce demand, labor availability, and what can be done for recruitment and training.

Strauch said that there is not an issue with companies violating visa rules that allow Canadian haulers operating in Maine. Last month, Maine Senate President Troy Jackson, D-Allagash and U.S. Rep. Jared Golden, D-Maine 2nd District, issued a news release saying they were disappointed the Farm Workforce Modernization Act passed by Congress didn't "close a loophole" that they said costs American jobs.

Strauch, though, said there is no loophole, and subcontractors that hire Canadian truckers are bonded and inspected, ensuring they abide by the rules of the HB2 visas. The program has an elaborate application process, overseen by the state Department of Labor, and companies that hire Canadians under the program have to show they didn't have qualified American applicants to fill the jobs.

He said it's a misconception that those who work in the U.S. under the visas can't haul point-to-point within the U.S., one issue Jackson had with the program. The hauling companies "can bring workers in from Canada if they have the need, and they often work in teams with U.S. workers," he said.

He said the real issue is there aren't enough truckers. Last year, there were 97 work requests under the visa program, but only 47 jobs were filled. "Historically, there's been a real shortage of truck drivers," Strauch said.

That shortage, as well as a shortage of workers to cut the timber, and other industry-related jobs is all part of what FOR/Maine is tackling, he said.

"All the parts need to be healthy," he said. "We have to reclaim some of the markets that have been lost" as well as tackle new ones.

0 Comments