'Cobots’ from around the world gather at UMaine’s high-tech training center

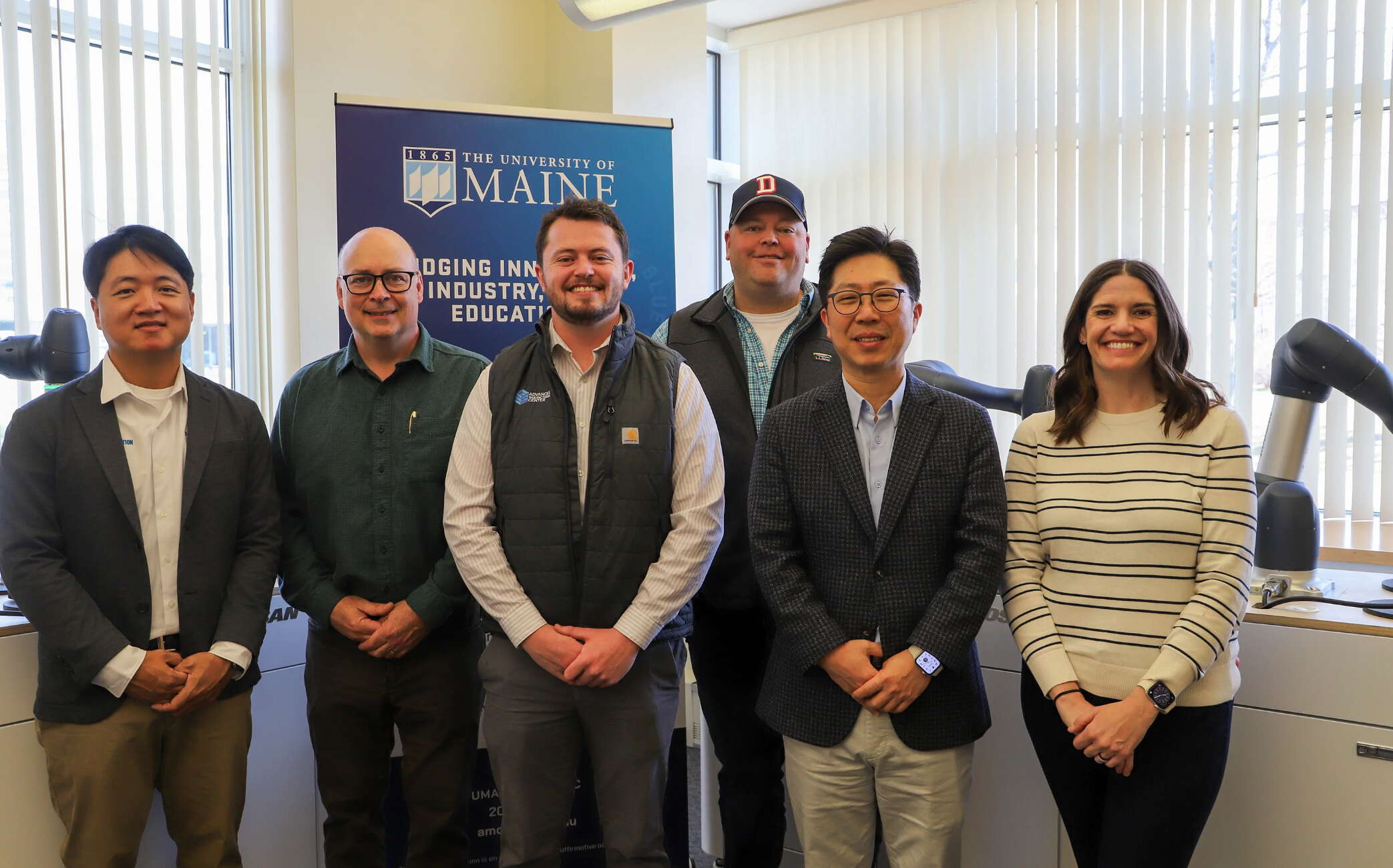

Photo / Courtesy UMaine

This collaborative robot, manufactured by Fanuc, would be used in pick-and-place automation.

Photo / Courtesy UMaine

This collaborative robot, manufactured by Fanuc, would be used in pick-and-place automation.

Collaborative robots, called “cobots,” from South Korea, Japan, Denmark and the U.S. are part of robotics and automation training facility that opened at the University of Maine’s Advanced Manufacturing Center in Orono.

The so-called B.O.T. Loft — short for "build, optimize and train" — is outfitted to address a growing need for skilled workers for “Industry 4.0” manufacturing that uses digitally advanced robotics and automation.

The facility will offer factory-authorized training, K-12 programs, hands-on curricula and credentialing programs to prepare workers for careers in robotics and automation.

“As manufacturers nationwide modernize, so too must our workforce,” said Joan Ferrini-Mundy, UMaine’s president and UMS vice chancellor for research and innovation.

“By collaborating directly with employers, we are creating targeted pathways to meaningful careers and ensuring Maine’s manufacturing sector has the highly skilled workforce it needs to thrive and compete globally using the most advanced technologies.”

International robots

The 3,600-square-foot facility is equipped with equipment from Doosan Robotics in South Korea, Universal Robots in Denmark, ABB Robotics in Switzerland with a U.S. headquarters in Michigan and Fanuc in Japan.

The loft is funded through the U.S. Department of Defense Industrial Base Analysis and Sustainment/Industrial Capabilities and Modernization Program. In the fiscal year 2023 federal budget, U.S. Rep. Jared Golden, D-2nd District Maine, at the request of the University of Maine System and with the support of Maine’s congressional delegation, secured $7 million in federal funding for UMaine to lead the creation of two “Industry 4.0” manufacturing training innovation centers designed to provide talent pipelines for defense, aerospace and other manufacturing employers in the state.

“Industry 4.0” refers to digital advancements in manufacturing.

The B.O.T. Loft is the first of those facilities, with a second underway at Southern Maine Community College.

“This facility is a direct investment in Maine’s workers and our manufacturing future,” said Golden. “With top-tier training at Maine’s flagship university, we are creating a direct pipeline for the skilled technicians our defense industry and local businesses desperately need.”

Industry collaborations

The facility provides a flexible learning space where students and incumbent workers can gain experience with industry-standard advanced manufacturing equipment. The training programs are designed to be accessible, offering stackable credentials that allow participants to build skills over time and advance in their careers.

“Based on recent studies completed by the AMC and partners, having a cohort of trained operators and technicians is essential to help company managers develop the confidence to embrace automation and robotics,” said John Belding, director of the Advanced Manufacturing Center. “The B.O.T. Loft is the next stage in the AMC’s longstanding commitment to help companies trial and de-risk the adoption of these technologies, and to train workers with the skills needed to operate them.”

Portland-based Industrial Automation Supply, an electrical controls and automation components distributor led by Mark Chapman, facilitated the relationship between UMaine and South Korea-based Doosan Robotics and provided Doosan’s collaborative robots to the facility. Doosan will support the center with training materials, structured lesson plans and educational robot kits.

"This was a tremendous opportunity for IAS to help with bringing collaborative robots to the next generation of manufacturers and engineers," Chapman said of the relationship with UMaine. “We’re not just providing the cobots to the workforce, we’re actively working to educate and familiarize tomorrow’s workforce leaders to this technology — making it so today’s students aren’t just ready, but comfortable with what they will see in the robotic workspace by working intimately with them as part of their curriculum.”

The Advanced Manufacturing Center is an engineering support and service center that helps move ideas from concept to production through hands-on prototyping, design and fabrication services for companies across the state. It also provides workforce development programs.

0 Comments