Factory 3 maker space in Portland fills niche for startups and small businesses

Photo / Courtesy Factory 3

Patrick Russell opened Factory 3, a maker space and creative hub at 105 Saint James St. in Portland, in response to lack of affordable space for artists and makers.

Photo / Courtesy Factory 3

Patrick Russell opened Factory 3, a maker space and creative hub at 105 Saint James St. in Portland, in response to lack of affordable space for artists and makers.

Patrick Russell opened Factory 3, a 4,400-square-foot maker space and creative hub at 105 Saint James St. in Portland, in October 2019 with 15 members on day one and 70 today.

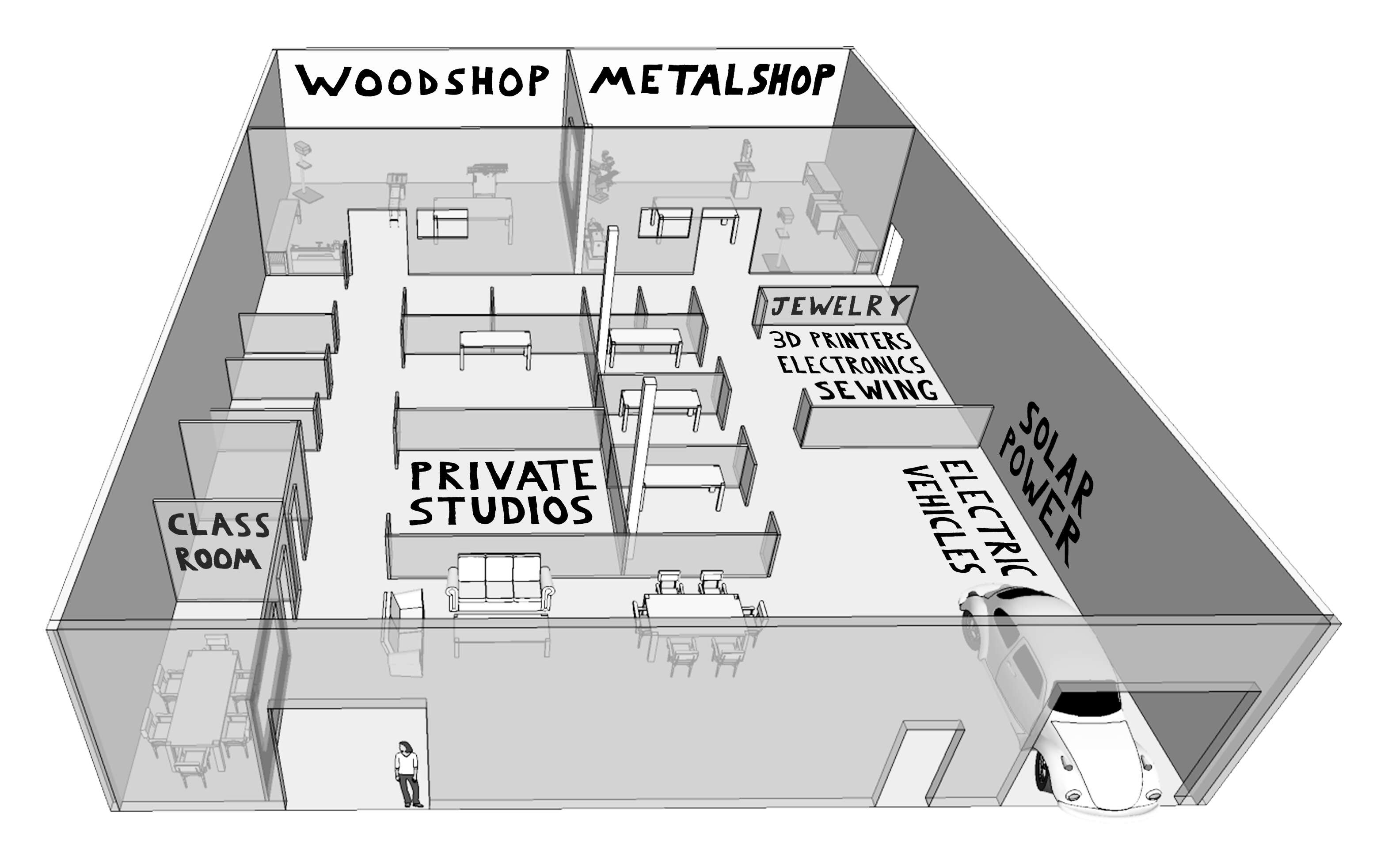

Awarded the 2025 "Small Business of the Year" by the city of Portland, Factory 3 — signifying the maker movement as the third industrial revolution — offers facilities for woodworking, metalworking, fiber arts, 3D printing, laser cutting, bike repair, electronics and design; and private studios and classes.

Mainebiz: What’s your background?

Patrick Russell: I went to Northeastern University, graduating with a business degree concentrating in entrepreneurship. I worked in sales in Boston, moved to Portland in 2009, started Walker Film Production and ran that for eight years.

MB: Why did you start Factory 3?

PR: In 2009, space was cheap and readily available in Portland, with a lot of workspace for artists and makers. As rents went up, a lot of creative folks didn’t have space to work.

MB: What kind of location did you want?

PR: On or as close as possible to the peninsula. Affordable. In an industrial zone. A big, open space so we could build out. High ceilings. I looked for about a year. I was shopping at Gilman Electrical, near the building where Factory 3 is now, and saw that the building had become available. It was perfect.

MB: What was involved in getting in there?

PR: I secured a lease and exercised the options to buy in November 2018. It took about a year to build out. It was a cinderblock shell — no plumbing, no heat, minimal electrical, old fluorescent lights. We built up walls, installed electrical. I dug a trench for the pipes.

MB: Equipment?

PR: I installed equipment for the metal and wood shops. We have a couple of 3D printers, a laser cutter and a full sewing shop. Some makers bring their equipment.

MB: How much have you invested?

PR: A fair amount, financed mostly with my own savings. Several grants through the Maine Department of Economic and Community Development and the city. A loan. Donations when possible. Cash flow from the business. A ton of sweat equity.

MB: Did you use startup consultants?

PR: SCORE was incredibly helpful. I did some work with the Maine Small Business Development Centers. I had my own network of mentors. I knew the basics from my video company. But there was a lot to learn.

MB: What’s your member mix?

PR: Early 20s to late 70s, different economic backgrounds. Someone looking to start a business or work in the trades. They need access to a building suitable for this type of work. It’s hard to get that without a long-term lease and a proven business model. Equipment can be expensive. They might need training on the equipment.

Art school graduates who lost access to that equipment. One member is starting a business making guitar amps. People might downsize and don’t have space for tools. Furniture-makers. One member is working on a backgammon board. A lot of custom fabrication. Painting, drawing, sculpture.

MB: Have businesses emerged?

PR: Several started here and expanded into their own commercial space. About a third of members are generating full- or part-time income. It’s definitely a business incubator.

MB: Examples?

PR: Underdog Candles started in her kitchen, became a Factory 3 member and recently got an 800-square-foot commercial space in Westbrook. Woodworkers started here, then expanded out. Emily Heath started a sewing and alterations business and is now on Commercial Street. A blacksmith, Kieran Chapman of Soma Metalwork, was a Factory 3 member for a few years.

MB: What's your revenue-generating model?

PR: Monthly membership fees. Some members pay an additional fee for a private workspace. We run over 60 classes, splitting fees 50/50 with instructors.

MB: Any further plans?

PR: We’re launching virtual classes so we can expand our reach. I’m looking into building a second floor on the roof.

MB: What’s your marketing strategy?

PR: Our most effective marketing, which I did before we opened and still do, is going into other businesses and asking to put up a flyer. That’s gotten a good amount of people. I send out email newsletters once or twice a month. We post on social media. Google search helps people find us.

MB: What do you like most?

PR: You can feel a creative energy in the air when you’re in there with a bunch of people all working together.

0 Comments