Interphase brings high-tech pellet boiler stateside

When ReVision Heat was founded in 2008, the goal was simple: Reduce the amount of fossil fuels needed to heat Maine homes, primarily through the installation of pellet boilers.

But at an average cost of $19,000, those pellet systems were out of the range of most Mainers, according to Ryan Hamilton, a managing partner in a sister company of the Portland-based heating contractor. In ReVision Heat's first four years, it sold only 30 pellet boiler units, he says.

Now Hamilton and some of ReVision's founders have established a new company, Interphase, to import lower-cost pellet boilers from Denmark. In the last four months, Interphase has sold 20 units and is now selling 1.5 pellet boiler systems per week, putting the company on pace to reach its short-term goal of 100 per year.

"We're almost there right now, and that's with no marketing," says Hamilton, who shares a managing partner title with many of the owners of ReVision Heat and its sister company, ReVision Energy.

Interphase is now the exclusive North American dealer of the pellet boiler system developed by Denmark's NBE. The designation gives the company the potential to do as much as $20 million in sales over the next five years, according to Hamilton.

"To date, there hasn't been a pellet boiler that has been affordable to the masses," he says.

The NBE business model emphasizes high sales volume and low profit margins, which allows Interphase to install its pellet boiler system at a cost of about $9,000 for the most basic model.

The lower purchase and installation cost opens the door to more savings for homeowners interested in converting from oil-fired heating systems.

"If we can be in the $8,000 to $15,000 range, that's a really healthy price point because for the average home there is about $1,500 in savings every year [over] oil," says Pat Coon, Interphase managing partner. "We can cost $5,000 more but have a four-year payback on that price difference."

Boilers versus stoves

Interphase is focused on selling boiler systems, rather than wood pellet stoves, says Jacob Roberson, another managing partner. Pellet stoves are best suited to heat a single room, and often require supplemental heating sources, whereas a pellet boiler is designed to replace an oil burner and feed directly into a home's central heating system.

"A stove is secondary. It's for ambiance and taking the edge off your oil bill, but this is your primary heating source," he says, noting the average home in Maine burns 800 gallons of oil a year. A pellet stove can lop 200 to 300 gallons off, but a home owner still burns 500 to 600 gallons of oil.

Interphase also focuses on establishing a strong distribution network, partnering up with well-known names in the local energy fuels markets, like Daigle Oil Co. in Fort Kent and Heutz Oil Co. in Lewiston, which sell both the system and the pellets to feed it.

"It's nice because they have a really strong presence and marketing program that we are able to leverage," says Roberson.

While it might seem like oil companies would be undermining their own interests in selling and supplying pellet stoves, Roberson says that the proliferation of pellet heat is a win-win.

"While we are competing with oil boilers, we're not necessarily competing with those providers," he says. "We're actually providing tools for them because they see their margins going down at the fuel pumps and see their customers struggling to heat their homes. This product is really another arrow in their quiver."

Technology

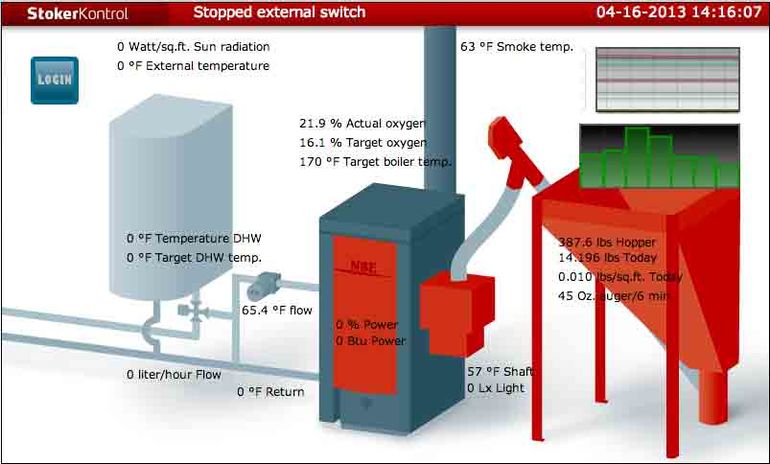

The pellet boilers, which are sold under the name Kedel, come with a web-based interface managed by NBE that allows users, and Interphase, to monitor and control the system off-site.

"If someone calls and says it's overfeeding, I can go online, look at the oxygen levels and make adjustments through the web interface," says Hamilton. "I just completed a service call without leaving my desk."

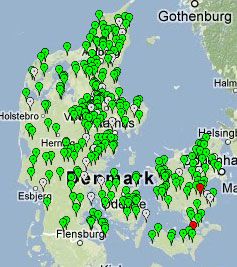

The web interface is also useful for pellet suppliers. Thanks to a map that plots every Kedel currently in use within the region, a supplier could consult it before heading out on a delivery to see if any other Kedel users along the route are in need of a refill.

NBE scouted distributors across Maine, New Hampshire and upstate New York last year "because they saw this area as a lead market in changing over to pellets mainly because the residential bulk delivery infrastructure is growing," says Hamilton.

In the end, NBE chose Interphase, a decision that Hamilton credits to his company's mechanical contracting background.

"They could have gone with some big distributor and they might have been able to move more products, but that level of support and understanding wouldn't have been there," he says.

Interphase currently has 10 mechanical contracting partners spanning as far as Poland, N.Y., who sell and service the Kedel systems.

The arrival of Icelandic shipping company Eimskip to the Portland market was a timely boon to the fledgling distributor, saving Interphase an estimate 20% on shipping costs while cutting transit time and allowing the company to shorten its trade cycle.

"We can cut that eight weeks to six and carry less inventory while keeping our vendors happy," says Coon.

Maine's wood basket

The pellet-based heating system also creates a sustained demand for locally harvested wood, says Hamilton. The company holds up Maine Woods Pellet Co. as an example of the potential for locally sourced fuel. The Athens mill produced 80,000 to 90,000 tons of wood pellets last year — the equivalent 238,000 barrels of oil — and is about to bring a delivery truck online to complement its wholesale business.

Mike Wilson, senior program director with the Bethel-based Northern Forest Center, says the organization sees high-efficiency pellet boiler systems as a great opportunity to keep Maine's energy dollars circulating in the regional economy.

"The Northeast U.S. is more dependent on imported fossil fuels for heating than any other part of the country," he says. "At the same time, we have an abundant wood fuel supply."

His organization is tasked with helping communities benefit from forest conservation and economic initiatives. It launched a program in Berlin, N.H., in 2011 to get 40 pellet boilers installed in the region to help promote the idea of high-efficiency systems.

So far, 37 Austrian OkoFEN pellet boilers have been installed, earning the region the distinction of having highest concentration of pellet boilers in the country.

"We are focused on helping people learn and understand that this technology is proven, reliable and saves money while keeping our heating dollars in the region and helping to support jobs," says Wilson.

While Wilson has not worked directly with Interphase, he says he is interested to see how the boiler is received in the Maine market.

"Two of the biggest challenges are public understanding and price point, so any opportunity to bring down the price of the system, we see as a positive," he says.

Mainebiz web partners

Ryan Hamilton of Interphase Energy shows off a high-tech wood pellet boiler — which is different than a pellet stove — that his company imports from Denmark.

1 Comments