Processing Your Payment

Please do not leave this page until complete. This can take a few moments.

- News

-

Editions

View Digital Editions

Biweekly Issues

- December 15, 2025

- December 1, 2025

- Nov. 17, 2025

- November 03, 2025

- October 20, 2025

- October 6, 2025

- + More

Special Editions

- Lists

- Viewpoints

-

Our Events

Event Info

Award Honorees

- Calendar

- Biz Marketplace

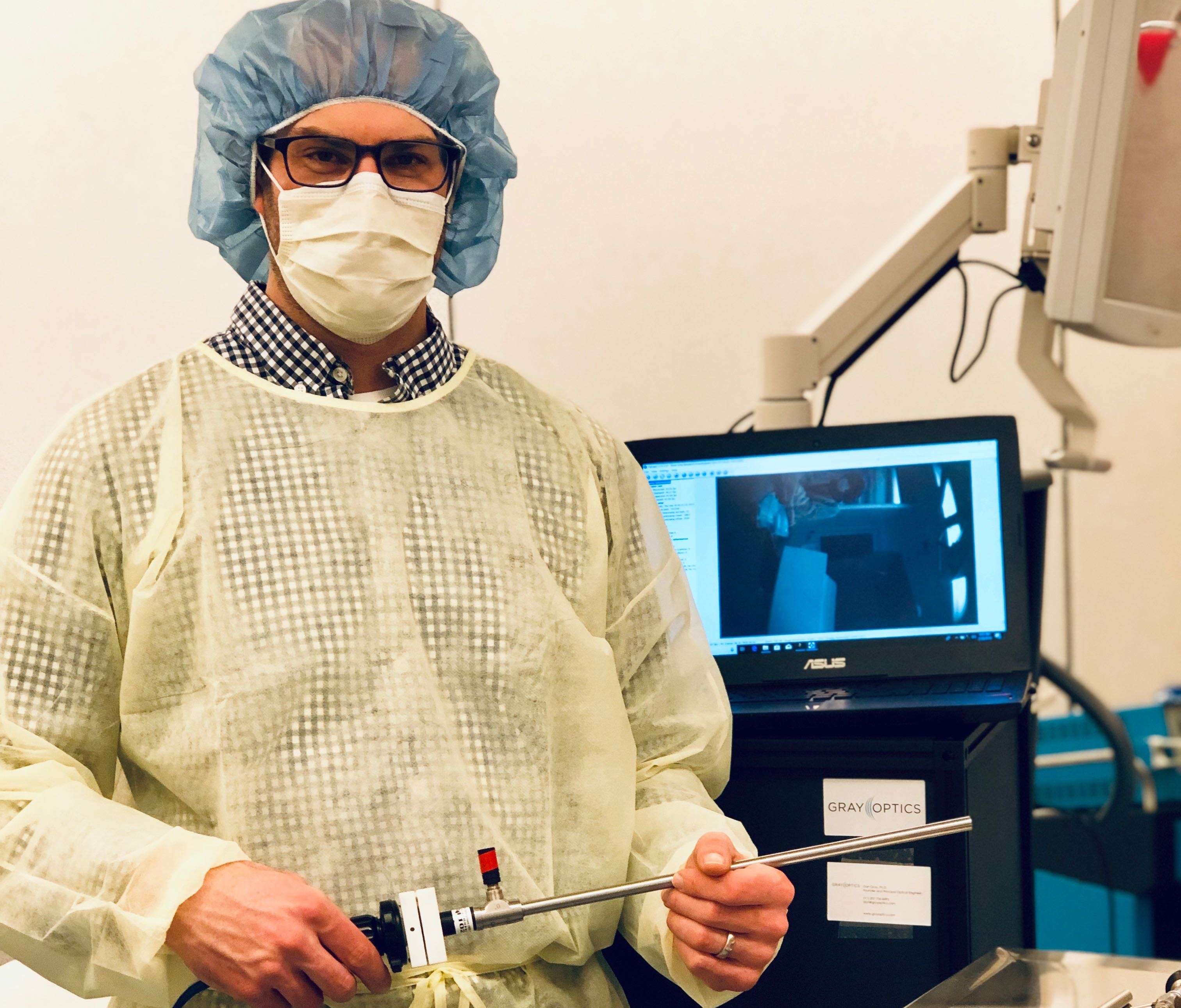

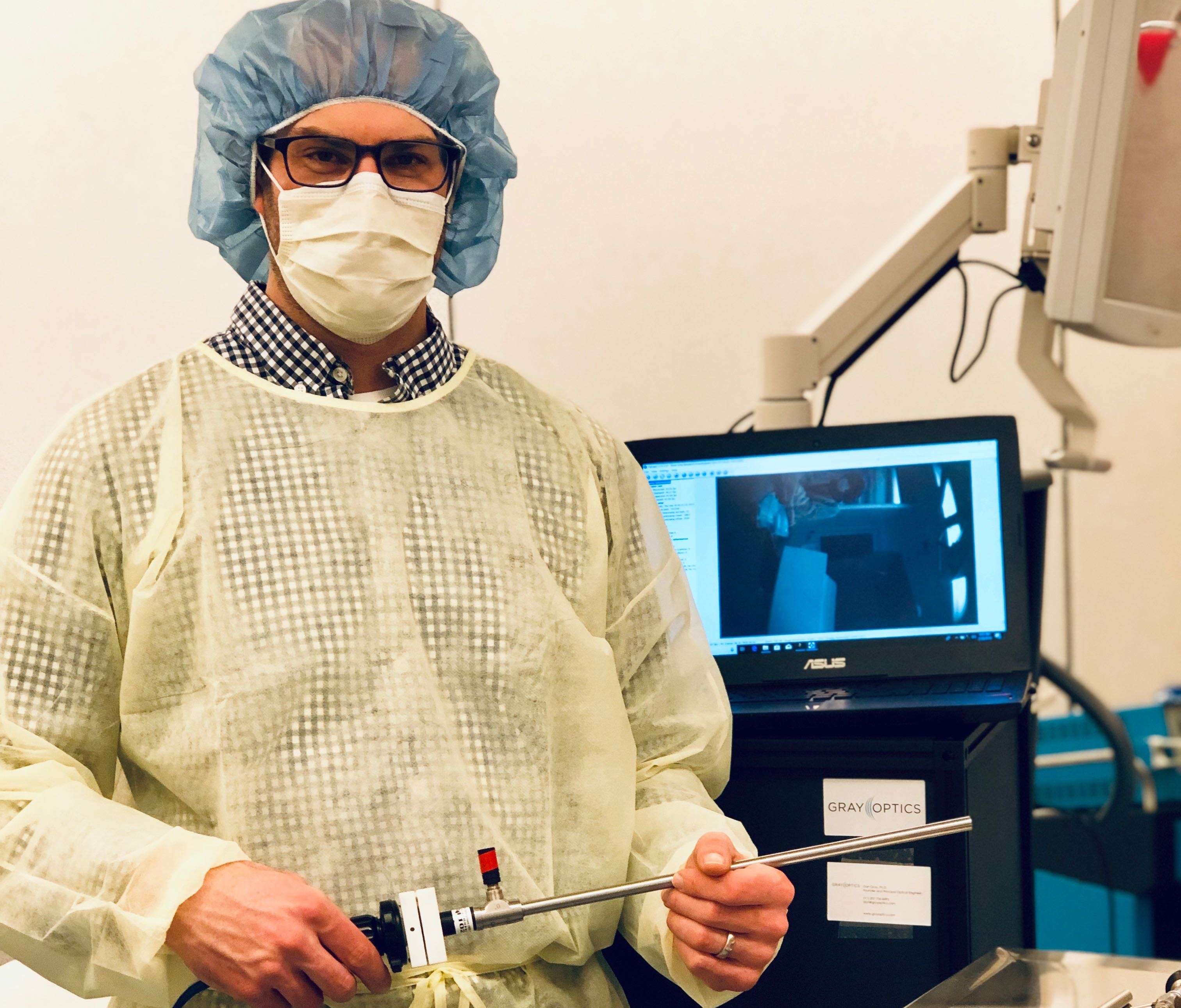

Q&A: Portland’s Gray Optics sees demand for precision components in COVID-19 tests

Founded in 2017, Gray Optics develops advanced imaging technologies and optical systems for biomedical, life sciences and industrial applications.

This year, the Portland company saw a surge in demand from manufacturers of COVID-19 “point-of-care” tests, which provide disease detection and diagnosis within minutes. Test manufacturers have come to Gray Optics asking for customized optical systems that are an integral part of the tests.

The challenge? Many rapid tests rely on fluorescence detection using a lens that must be precisely aligned, with regard to specifications such as field-of-view and depth-of-field, to a digital image sensor. The Gray Optics team designed those precision optical components for manufacturing at scale.

Faced with aggressive product development schedules to meet the pandemic demand, the company doubled its staff. Going into 2021, Gray Optics expects to continue to expand its staff as well as its facility space.

Founder Dan Gray, born and raised in Northampton, Mass., studied optics at the University of Rochester, where he received bachelor's, master's and Ph.D. degrees. Interested in entrepreneurship, he also took business courses and created a business plan to commercialize the technology he developed during his research. After graduation, he worked at various optics technology companies, then combined optics and entrepreneurship to found Gray Optics.

Mainebiz asked Gray about the company’s evolution and how demand for COVID point-of-care tests is accelerating its expansion. Here’s an edited transcript.

Mainebiz: How did you come to start your company in Maine?

Daniel Gray: I was living and working in the Albany area at General Electric in a research-focused department. I realize I’m motivated by the later stages of the technology development process, where there’s a strong chance that the work goes into a product that impacts people positively.

So I left General Electric and came to work for an imaging company in Maine. My family fell in love with the area, and we decided to stay. That provided the opportunity to start Gray Optics.

MB: What did the company look like initially?

DG: In 2017, it was just me. There was no investment or funding. I was interested in providing design and consulting services, starting with my professional network. After three months of contacting people in my network, I had more than enough work and started building our team. In 2018, we finished the year with three employees. In 2019, we finished with five. Now we’re at 17.

MB: What types of clients do you work with?

DG: In the medical space, we support customers developing surgical robotic systems, retinal imaging, dental cameras — anything that uses a camera to take pictures of people.

For life sciences, optical technologies are used for diagnostics or analytical applications such as tissues and blood sample specimens.

Industrial markets use similar technologies for inspecting mechanical systems. For example, an aircraft engine has thousands of parts. You don’t want to take it apart to inspect it, so having a flexible inspection camera, or ‘borescope,’ to do inspections is valuable.

We also work on 3D printing, where lasers, mirrors and lenses are critical.

MB: What’s a product development problem you’ve worked on?

DG: A startup company in Boston is innovating visualization for minimally invasive surgery, using an endoscope that’s inserted into a port within the body. They’re providing the surgeon with pictures of the anatomy that can’t normally be seen with their own eyes.

We worked on the lens design. The company had developed the basic functional product requirements through their prototypes. We did the commercial product design for them, paying attention to things like manufacturing tolerances, material choices and the assembly process.

MB: How did you get the lens design from prototype to manufacturing?

DG: We developed this product in about four months. We broke it down into phases. We understood what the requirements were, developed an initial design concept, reviewed it with the customer, then improved the design. Then we did a tolerance analysis that included more details for manufacturing. We ordered parts through our supply chain, assembled completed lens systems, then tested it to confirm that what we designed would work to the customer’s requirements.

MB: How is optics used in COVID point-of-care testing?

DG: The presence of COVID can be detected through fluorescence imaging: In simple terms, does the sample glow a specific color or not? The COVID sample goes through an assay [a process for analyzing a sample] that uses a mixture of chemicals and compounds that include fluorescence labels.

The result can be read by an optical system. The technology uses light sources, cameras and filters.

MB: We know you can’t name clients, but in general, who are the COVID-19 test manufacturers connecting with you?

DG: North American-based, primarily. We have several customers who have either pivoted their product to or created a COVID specific test.

MB: What do your growth trends look like now and how have you financed that?

DG: To date, we haven’t taken any investments.

We have global customers — a strong focus in the U.S and Europe, but also in Asia, Australia and elsewhere in the world.

In 2020, we expanded our core engineering and program management teams, as well as formed Gray Optics' senior leadership team, consisting of highly experienced professionals with extensive backgrounds in sales, operational finance and advanced manufacturing in medical, life science and industrial markets.

Building on this for next year, we are forecasting further growth in the company and making plans to continue to hire local talent and planning investments to expand our manufacturing to support the needs of our customers.

MB: What are you looking at for new space?

DG: Currently we’re in a 3,000-square-foot flex industrial space, with several offices and an assembly and test space. We’re looking for 10,000 to 20,000 square feet. Our move could be the end of 2021 or the beginning of 2022.

MB: Any advantages to being in Maine?

DG: Quality of life — size of the community, outdoor activities — the coast, the lakes, the mountains, Portland’s vibrant downtown. And there’s a pretty good local workforce to support technology development.

Mainebiz web partners

Way to go son-in-law!

The Giving Guide

The Giving Guide helps nonprofits have the opportunity to showcase and differentiate their organizations so that businesses better understand how they can contribute to a nonprofit’s mission and work.

Learn More

Work for ME

Work for ME is a workforce development tool to help Maine’s employers target Maine’s emerging workforce. Work for ME highlights each industry, its impact on Maine’s economy, the jobs available to entry-level workers, the training and education needed to get a career started.

Learn More

Groundbreaking Maine

Whether you’re a developer, financer, architect, or industry enthusiast, Groundbreaking Maine is crafted to be your go-to source for valuable insights in Maine’s real estate and construction community.

Learn more-

The Giving Guide

The Giving Guide helps nonprofits have the opportunity to showcase and differentiate their organizations so that businesses better understand how they can contribute to a nonprofit’s mission and work.

-

Work for ME

Work for ME is a workforce development tool to help Maine’s employers target Maine’s emerging workforce. Work for ME highlights each industry, its impact on Maine’s economy, the jobs available to entry-level workers, the training and education needed to get a career started.

-

Groundbreaking Maine

Whether you’re a developer, financer, architect, or industry enthusiast, Groundbreaking Maine is crafted to be your go-to source for valuable insights in Maine’s real estate and construction community.

ABOUT

NEW ENGLAND BUSINESS MEDIA SITES

No articles left

Get access now

In order to use this feature, we need some information from you. You can also login or register for a free account.

By clicking submit you are agreeing to our cookie usage and Privacy Policy

Already have an account? Login

Already have an account? Login

Want to create an account? Register

Get access now

In order to use this feature, we need some information from you. You can also login or register for a free account.

By clicking submit you are agreeing to our cookie usage and Privacy Policy

Already have an account? Login

Already have an account? Login

Want to create an account? Register

1 Comments