Bar Harbor council skeptical of salmon farm proposed in Frenchman Bay

Screenshot Courtesy / American Aquafarms

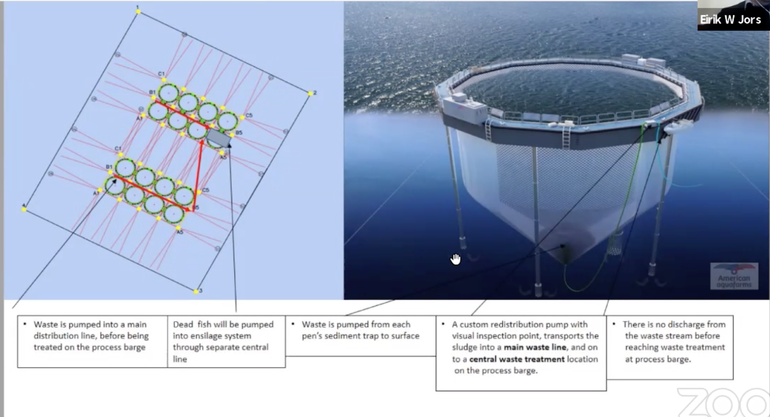

At right is a rendering of a rigid aluminum closed-pen system.

Screenshot Courtesy / American Aquafarms

At right is a rendering of a rigid aluminum closed-pen system.

Several members of the Bar Harbor Town Council expressed reservations about a large salmon farm proposed on two lease sites off the town’s shore.

“The potential for something to go wrong is so great, it seems to me you’re suggesting we allow our bay to be a sacrifice zone for your experiment on the coast of Maine,” Councilor Gary Friedmann told American Aquafarms Vice President Eirik Jors during the council’s virtual meeting on Tuesday.

“This technology allows a new type of thinking in the aquaculture industry,” Jors responded, referring to the proposal’s use of a “closed-pen” system that he said is considered an emergent but also safe technology for fish-farming.

Jors and the company’s founder and CEO, Mikael Rones, gave a presentation to the council from their home country of Norway. Rones noted they hope to be able to travel to the U.S. in a few months as pandemic restrictions lift.

American Aquafarms, established by Rones in 2019, recently filed draft applications with the Department of Marine Resources for two 20-year lease sites. The proposal is to develop a closed-pen, ocean-based salmon operation in Frenchman Bay.

The two proposed sites are off the town of Gouldsboro to the east and Bar Harbor to the west. The company plans to establish a hatchery, fish farm facilities and a state-of-the art processing plant. The company has entered into an agreement to purchase the Maine Fair Trade Lobster facility in Gouldsboro, with plans to redevelop the 11-acre site into a hatchery and processing facility.

According to the presentation, Rones previously founded several companies in the aquaculture sector, most recently Norcod, a Norwegian cod farm.

Jors worked as an advisor, broker, analyst and investor within the aquaculture industry. He is the founder and CEO of a Nordic securities firm.

Jors said that some advantages of the closed-pen system is that it’s a “proven and robust” technology with “significantly less” risk than conventional open-net finfish farming. Closed pens, he explained, controls discharge, eliminates fish escapes, reduces the need for medicine and chemicals, and eliminates sea lice and predators.

Site search

American reviewed the entire New England coastline for potential sites and found Maine was the best fit for closed pen operations, he continued. In Maine, they reviewed several bays along the entire coastline. They settled on Blue Hill Bay and Frenchman Bay as the likeliest options, then determined that Frenchman Bay would be best due to ocean conditions considered ideal for the closed-pen system. Considerations included water temperature, shelter from waves, speed of the currents, depth and water quality.

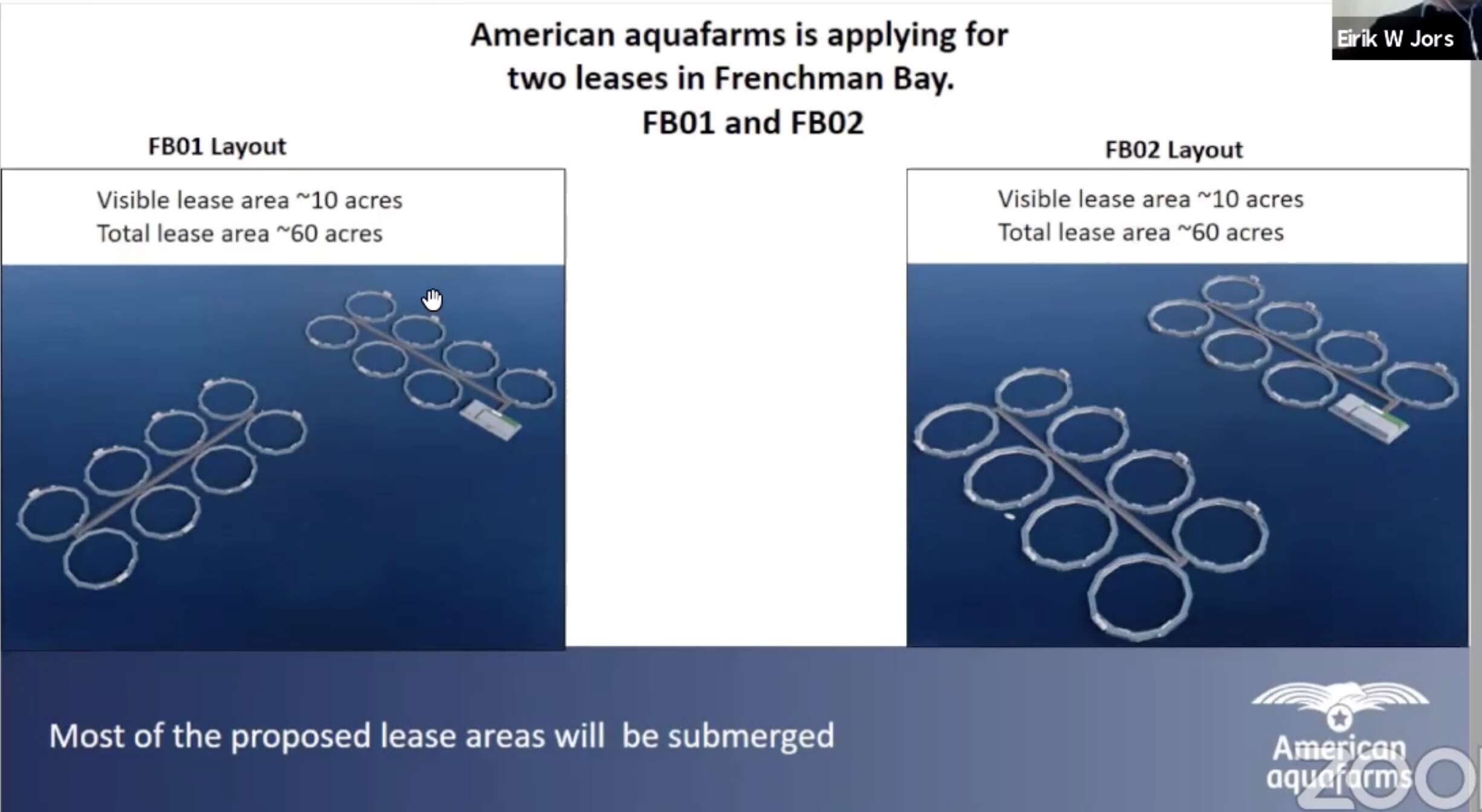

Each site would be 60.3 acres. The pens at each site would take up 6.6 acres. With associated mooring systems, the equipment would take up about 10 acres each. Most of the equipment would be submerged, Jors said.

The set-up has been refined to consider factors such as noise, lighting and aesthetic design, he said. For example, generators would be housed in a closed unit on the operation’s feed-and-waste barge, with a high degree of noise-reducing insulation. Light emissions would be shielded to protect the night sky. Equipment would be flat and nonreflective.

The sites are labeled “FB01”and “FB02.” The distance from both to Cadillac Mountain would be about 5.5 miles and to Bar Harbor 3.3 miles. Neither site would be visible from Bar Harbor, he said.

The marine route of the company’s boats from its base of operation in Prospect Harbor would traverse 12 and 15 nautical miles respectively.

Rigid aluminum

The pens’ outer framework would be made of rigid aluminum. Inside that would be a closed-membrane sack made of “ultrastrong” polymer, and inside that an additional net for a double layer of security, he said. The top of the pens, fitted with bird netting, would sit about one meter above sea level. The pens would be rigid and stable enough to withstand weather and currents, he said. The system can withstand 28 tons of force per square meter, far more than net pens used in conventional systems, he said.

The mooring system, to hold the pens in place, would consist of two grid systems, each with two rows of four cages. All together, the mooring grid would contain 15 pens and a waste barge.

A system of pipes on the outside of the structure would collect water at various depths that allow the operator to adjust the water temperature inside the pens, Jors continued. In the winter, for example, water would be collected from the lower warmer-water depths.

A cone-shaped structure at the bottom of the pen is designed to collect fish waste. The system can collect 90% of the waste coming out of the fish, Jors said. The waste is pumped out through a system of pumps and lines to a central main line that’s connected to the combined feed-and-waste barge. The discharge would then be treated further, transported to land, and repurposed for other commercial uses such as fertilizer or biofuel, he said.

“Although it’s called a ‘waste’ barge, we don’t consider it waste,” he added.

Dead fish would be collected in a separate device and processed into pet food or bait, he said.

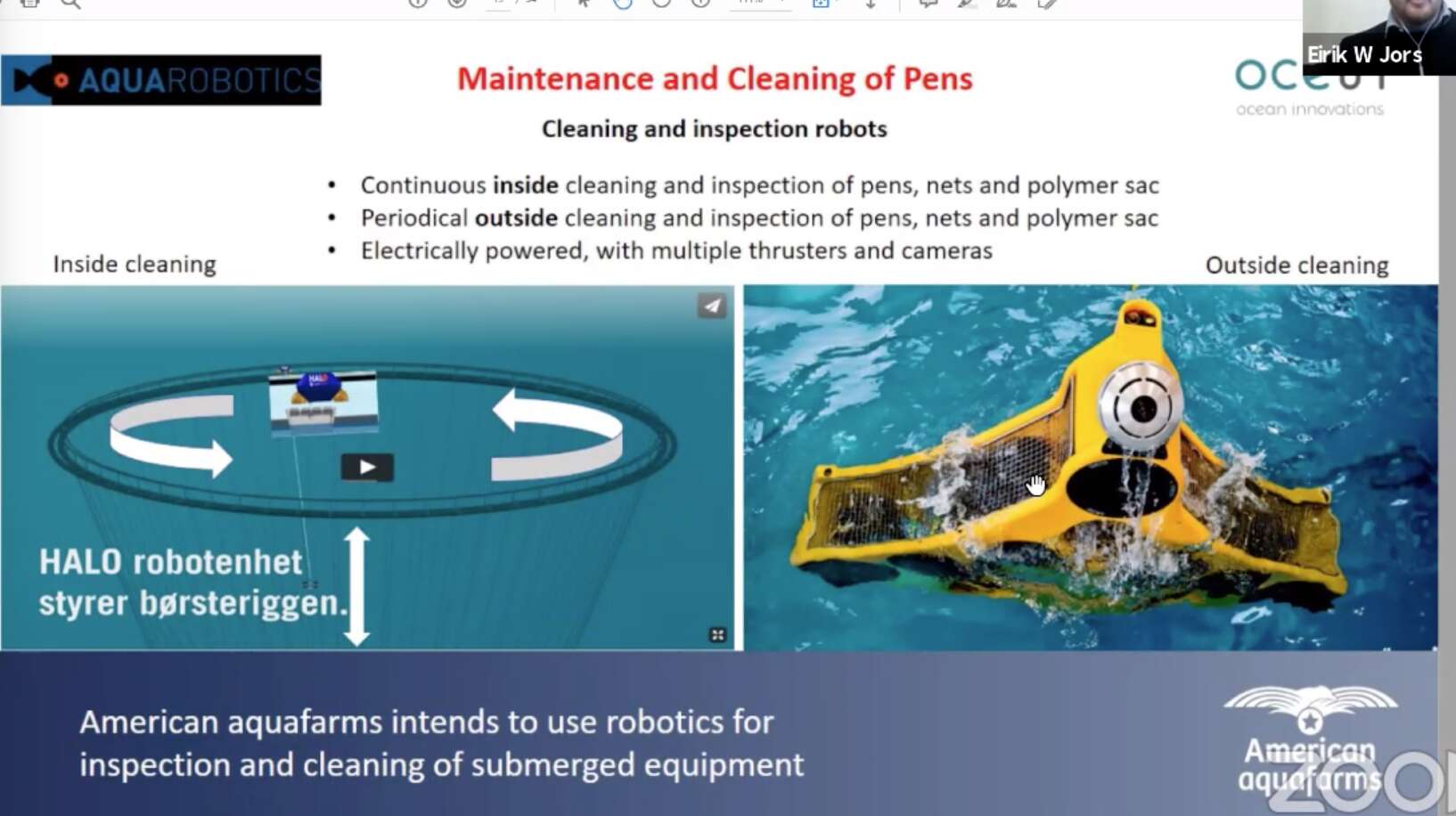

Robotics cleaning

Continuous cleaning inside the pens would be done by means of a robotics system that goes around and up and down 24/7. Periodic cleaning of the outside of the pens and of the mooring systems would be conducted via an ROV, or remotely operated vehicle.

The entire operation would be remotely controlled from the land facility, which would be manned 24/7 to provide continuous monitoring of factors such as the integrity of the system, fish feeding and water conditions.

American’s team has met with various interest groups, including local lobstermen, and has made adjustments to the project based on input, Jors said. For example, site layout and pen configuration have been adjusted based on input, he said.

The project has the potential “to create a large positive impact on the local economy,” Jors continued.

“We’ve done extensive research along the coast to find these locations and we believe this technology is both safe and the future of aquaculture,” he said.

Skepticism

But some councilors were skeptical.

“It seems to me you’re asking the state of Maine and our communities around Frenchman Bay to be the site of a test on an unprecedented scale for salmon aquaculture,” said Friedmann. “You’re talking about 1 million salmon being in pens in Frenchman Bay. You’re asking us to believe there will be no spills of fish feed, of fish waste, at a time when climate change is causing an increase in the frequency and intensity of storms. Accidents happen.”

Councilor Joe Minutolo said the council has been fielding local concern about the proposal. One of the biggest concerns, he said, is not only around potential environmental impacts but also about “industrializing our harbor and bay.”

Minutolo wanted to know how new the technology is.

“This is an emergent technology in Norway and other parts of the world,” responded Jors.

The number of local jobs to be created by the project is still in review, but it could be around 90 for the sea-side of the operation and “significantly higher” for the land-side, he said.

‘Quite large’

Fish feed would consist of organic plant-based materials and marine protein from wild fish sources, said Jors. Feed suppliers under consideration are members of a sustainable harvesting program, he added.

But, Friedmann asked, “Since salmon are carnivores, is it true you’re essentially importing fish that’s harvested in other parts of the world to add the protein to this particular aquaculture operation?”

Jors said the marine protein would come from processed remains that would otherwise be discarded.

Councilor Val Peacock wanted to know if the scale of the operation Would be considered “big” for the industry.

“Yes, it’s quite large,” said Jors.

Rones explained that the size of the proposal is dictated by the goal to run a year-round operation. By having 30 pens, he said, the company would be able to deliver fish to the process plant year-round, thus creating steady jobs.

Peacock also wanted to know, if the proposal goes through and the operation is successful, whether American Aquafarms would then seek to expand its lease sites.

“We will not look for other places for pens,” said Rones.

Rones said the main reason that every farm isn’t using a closed-pen system is because it’s a significantly higher investment than open-net systems.

0 Comments