Better bridges and roads: UMaine-led research coalition tackles the future of transportation

Photo / Fred Field

Habib Dagher, head of the Transportation Infrastructure Durability Center at the University of Maine, leads a coalition of universities throughout New England focused on identifying new materials and technologies that maximize transportation infrastructure investment.

Photo / Fred Field

Habib Dagher, head of the Transportation Infrastructure Durability Center at the University of Maine, leads a coalition of universities throughout New England focused on identifying new materials and technologies that maximize transportation infrastructure investment.

Drivers over the Penobscot Narrows Bridge are likely unaware there’s a small laboratory within the bridge where University of Maine faculty and students, in cooperation with the Maine Department of Transportation, have set up shop.

Using measurement tools like fiber-optic strain sensors and temperature sensors, the group is monitoring six high-strength, non-corrosive carbon fiber composite strands used in select spots on the structure, which otherwise employs conventional steel strands to hold up the bridge.

The goal is to see how well the carbon fiber strands perform. The idea is that composites, inherently non-corrosive, could provide better longevity than steel, ultimately saving cost.

The study is one of a number of projects being carried out by the Transportation Infrastructure Durability Center, a collaboration of New England universities led by the University of Maine. It seeks to identify new materials and technologies that maximize transportation infrastructure investment.

“There are hundreds of thousands of bridges and roads in need of repair,” says the leader of the program, Habib Dagher, a professor of civil and structural engineering at the University of Maine. “The DOTs are scraping for money just to keep things rolling.”

Funded by a $14.2 million, five-year U.S. Department of Transportation grant, the Transportation Infrastructure Durability Center is based at UMaine’s Advanced Structures and Composites Center, where Dagher is the founding director. The coalition includes six New England universities. Partners include state transportation agencies in five New England states, including Maine, and the American Society of Civil Engineers Transportation and Development Institute.

Long history

The Transportation Infrastructure Durability Center’s Maine-based projects build on work underway at UMaine’s composites center for two decades.

“We have a long history of working on these issues, and we have a well-known reputation of having made a big difference nationally in transportation-related research,” Dagher says.

An example that’s received national exposure is “Bridge in a Backpack.” The composite technology uses easily transportable flexible tubing that can be quickly assembled onsite and reinforced with composites and concrete to build an arch bridge. The system lowers construction costs and extends structural lifespan up to 100 years.

A spin-off company, Advanced Infrastructure Technologies LLC, commercialized Bridge in a Backpack and today there are more than two dozen such bridges around the world. This year, the company unveiled a composite tub girder system also developed at UMaine. The first tub girder bridge is being built in Hampden; it’s expected to be lighter and longer-lasting, with a lower life cycle cost, than traditional concrete and steel girders.

Cutting-edge

The Transportation Infrastructure Durability Center creates a collaborative framework among institutions and DOTs. The goal is to extend the life of existing infrastructure and construct new, longer-lasting assets. Like UMaine, other member universities have an extensive record of accomplishments related to transportation infrastructure. The center aims to build on those successes while introducing cutting-edge technology for potential application throughout the U.S.

There are four research areas:

- Develop improved road and bridge monitoring and assessment tools;

- Develop ways to strengthen existing bridges to extend their life;

- Use new materials and systems to build longer-lasting bridges and accelerate construction;

- Use new connectivity tools to enhance asset and performance management.

The Transportation Infrastructure Durability Center has 26 projects throughout New England, using 28 faculty researchers and 280 student researchers. The focus is on real infrastructure needs identified by DOT partners. Projects underway in other states include things like electromagnetic detection of concrete cracking, development of longer-lasting materials for asphalt mixtures and planning for flood mitigation.

A living structure

The study at Penobscot Narrows Bridge, to assess those six composite strands, is one of the Transportation Infrastructure Durability Center’s high-priority projects.

The composite strands were installed in 2007, a year after the bridge opened. UMaine’s composites center lab-tested the strands, along with a modified anchoring system, before they were installed. UMaine also placed sensors on the bridge to determine their performance and durability.

“The intent is to determine if the novel composite strands are performing the way they’re supposed to be,” says Roberto Lopez-Anido, UMaine’s Malcolm G. Long Professor of Civil and Environmental Engineering and the project’s principal investigator.

Over the summer, faculty and students visited the bridge’s lab to acquire data and compare it with data recorded there five year ago and 12 years ago.

“We’re trying to see if there are any changes over time,” Lopez-Anido explains. “The intent is to guarantee the longevity of the system. We know the material does not corrode.”

If all goes well after another two years of monitoring, MDOT could, potentially, partially or fully replace more steel strands; upfront costs will be balanced by long-term savings, he says.

Eventually, it will be useful to develop a remote monitoring system.

“And we’re thinking some of the data can be interesting for the public,” he adds. “For example, in the observation tower, we can have a monitoring screen where people can see real-time information on loads or stresses. They’ll be able to see it’s a living structure.”

Is that bridge okay?

Another project is led by William Davids, chair of the Civil and Environmental Engineering Department. He and his students are field-testing weight and flexing capacity of cast-in-place concrete T-beam bridges, a common structure.

The structures are often robust and in good condition. But they possess very low rating factors based on conventional testing protocols, which means many are given weight restrictions that might be unnecessarily low, Davids says.

Newer monitoring tools can provide a better understanding of how each bridge performs under high weights. Davids’ team has tested over 30 bridges for MDOT over the past seven or eight years; the work is now folded into the Transportation Infrastructure Durability Center mission. About two-thirds of the time, outcomes have allowed MDOT “to say, ‘Hey, the bridge is okay. We don’t need to post or strengthen it,’” Davids says. “That has implications for infrastructure longevity and costs.”

It also helps truckers and taxpayers.

“Can you imagine being in a rural state where you have sparse bridges, and suddenly a bridge shuts down that’s a main arterial?” says Dagher. “This helps people in Maine every day get to work and not have to take long detours. It also saves money if we can show that a bridge has another five to 10 years of life.”

Smart technology, harvesting energy from roads and remote monitoring are additional areas of interest.

“We have a faculty member who developed a remote camera system that can watch a bridge flex as traffic goes over,” he explains. “We can use that information to figure out the condition of the bridge is and if it’s degrading over time.”

He adds, “In the future, can self-driving cars become bridge inspectors if we equip them with the right tools?”

Pipeline to jobs

MDOT considers the Transportation Infrastructure Durability Center initiatives to be game-changers, says Dale Peabody, an MDOT transportation research engineer and TIDC advisory board chair.

“The durability center brings resources, funding and very smart people to help answer questions about how we can build things to last longer to begin with, and then how we can better maintain the infrastructure so we can be more efficient and more cost-effective,” says Peabody. “Our goal is to keep roads and bridges safe and to maintain them as long as we can, because there’s just not a lot of money to rebuild everything. This will help us directly in that regard.”

The real-life projects also benefit students, notes Lopez-Anido.

“We always try to involve students in these research projects,” he says.

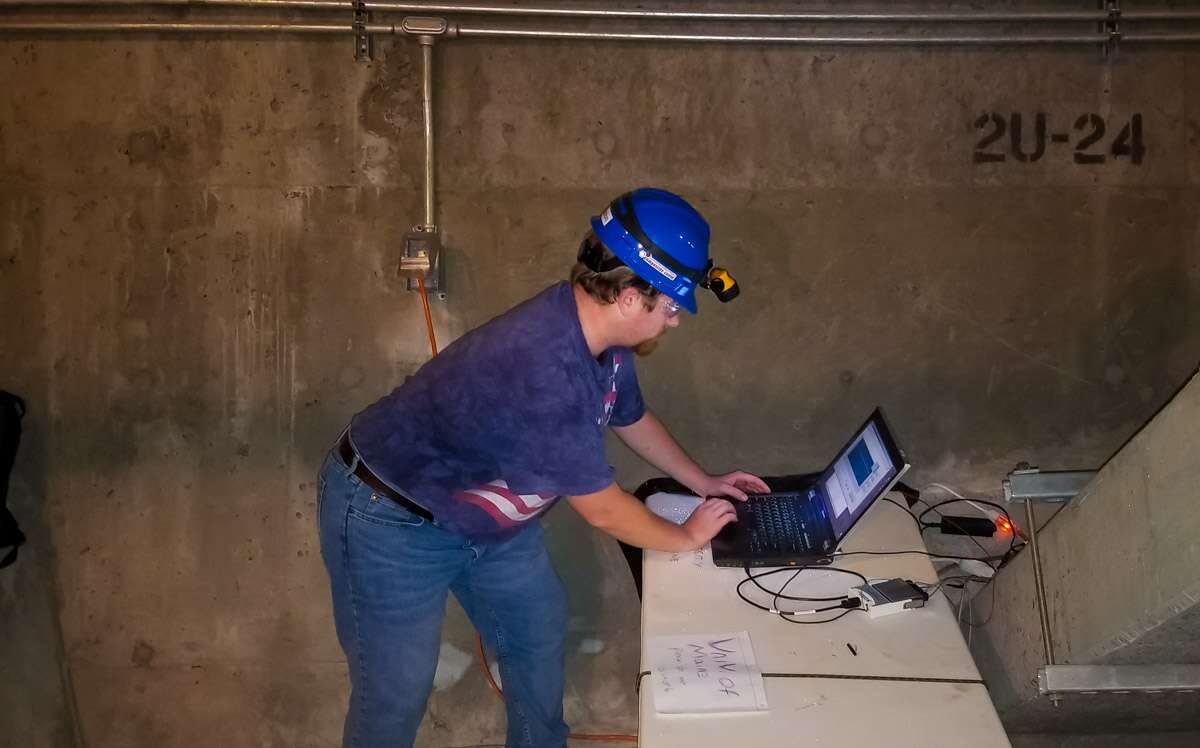

Braedon Kohler, who is studying for a master’s degree in mechanical engineering; was tasked with acquiring data at the Penobscot Narrows Bridge this summer. “His research focuses on monitoring this bridge and modeling the different responses of the bridge to be able to guarantee its durability and longevity,” Lopez-Anido says. “So he takes classes, works with instrumentation in the lab and at the site, acquires data, comes back to the lab and works with predictive models.”

The result is a pipeline to jobs.

“There will be many opportunities for him to present and get feedback on this work at the professional level,” Lopez-Anido says. “The fact that he’s part of the durability center’s activity gives him more visibility. So it’s not just the work itself, but the exposure. He also takes a leadership role. As we advance the project, we expect him to take the ball and run with it.”

0 Comments