Feeding an addiction to progress: Navy vet finds hidden rewards in machining program

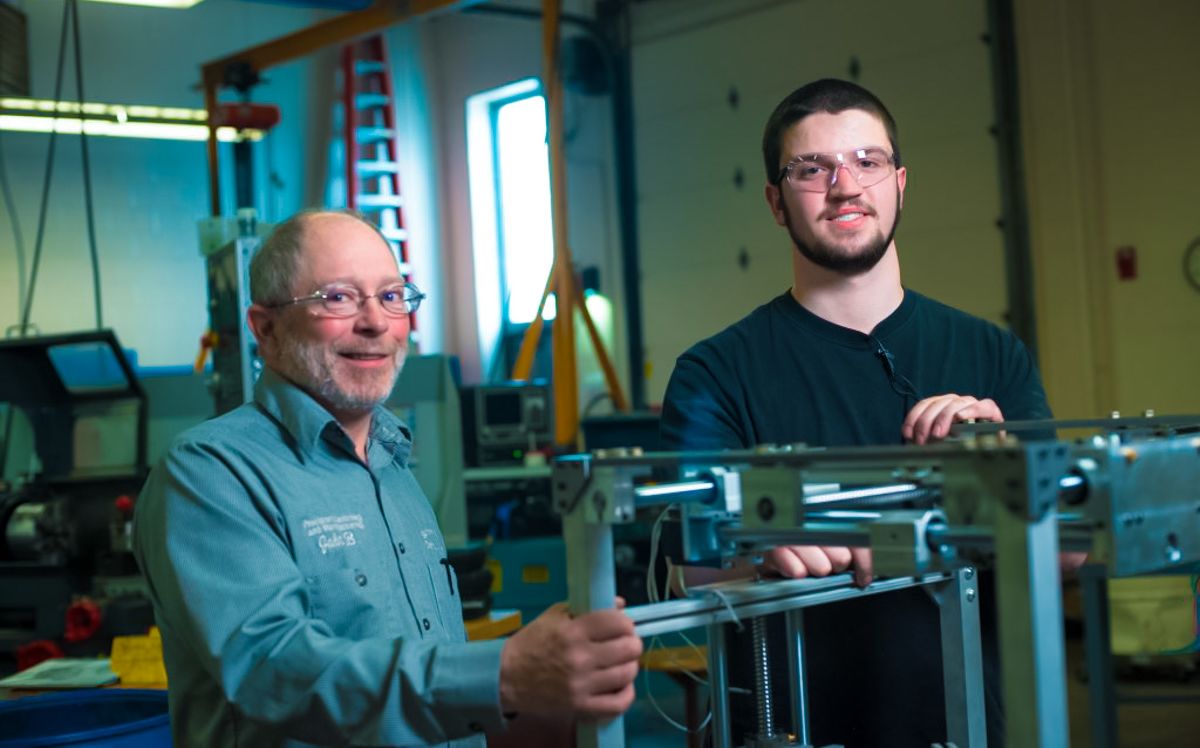

Photo / Courtesy SMCC

John Bolduc, left, is chairman of the SMCC Precision Machining and Manufacturing program.

Photo / Courtesy SMCC

John Bolduc, left, is chairman of the SMCC Precision Machining and Manufacturing program.

Benjamin Henckel has an “addiction to progress.” It’s what first attracted him to machining.

“I love to see things get completed, and working with my hands has always provided that satisfaction,” he says.

Henckel, 24, is in his first year at Southern Maine Community College, where he’s in the precision machining and manufacturing program. He was honorably discharged in August 2020 after serving in the U.S. Navy as an aviation ordnanceman attached to a helicopter squadron at North Island Naval Air Station in San Diego, and he wasn’t sure what his next step would be.

After driving cross-country back to Maine, his home state, with his brother, Max, he decided on SMCC because it’s a local school and he heard it had a good trades program.

The SMCC Precision Machining & Manufacturing associate degree in applied science program requires a mix of general education and hands-on courses. Graduates can find high-paying jobs in industries ranging from shipbuilding and aerospace to medical and consulting firms. Studies cover things like math, physics, engineering technology, manufacturing processes and methods, as well computer studies, business and liberal arts. The program also offers a certificate in Computer Numerical Controller Machine Operation, a shorter course of study.

John Bolduc, chairman of the department, says that what was once considered a blue-collar profession now calls technical know-how and critical thinking skills.

“They work in high-tech shops, with sophisticated equipment,” he says. Students have gone on to work at places like Bath Iron Works, the Defense Department and Abbott Laboratories, the Scarborough business that develops diagnostic testing including for COVID-19.

Job possibilities are endless, as are the Maine businesses looking for skilled manufacturing workers.

My students right now can pick whatever they want to do with their degree.

— John Bolduc, SMCC

“My students right now can pick whatever they want to do with their degree,” Bolduc says.

Bolduc fields constant phone calls from companies across the state looking for skilled workers. Many of the firms will pay for training, or reimburse a student’s tuition, if they can find someone to fill a position. “I could put 30 to 40 people to work today if I had the students,” Bolduc says.

The program also offers internships, something suggested by its industry partners, which allow students to get paid training, while companies fill empty slots.

Bolduc says students can complete the 90-hour internship any time during their course of study, and many of them are during the summer or after the students’ first semester so they interfere less with studies.

Henckel works at Standard Machine Co., in South Portland, a small machine fabrication shop.

“It’s a pretty small operation, just my boss and I,” he says. “He’s taken me under his wing and is really expanding my knowledge and experience.”

Henckel had no idea what he was getting into with machining. “So, it’s all been pretty surprising,” he says.

One surprise is a pleasant one. It’s less stressful than the Navy. Another is how precise the work is. “The tightness of some of the tolerances we machine can be astonishing. We regularly make parts that are within one thousandth of an inch and on occasion we work to one ten thousandth of an inch,” he says.

It’s really a lot of fun to make parts and if someone has a passion for creating anything, this could be the path for them.

— Benjamin Henckel, SMCC student

The work also fits his addiction to progress.

“It’s all very black and white. Either a part I make meets tolerances, or it doesn’t. I also get to have that little sense of accomplishment when I finish something. It’s very rewarding.”

He can see himself making a career out of the trade, but also sees the possibilities it can lead to. “I think as I age, I will want to move into the modeling and programming side of the industry,” he says. While he hates the idea of a desk job, he also has a lot of fun using Solidworks, 3-D CAD design software, to create pars on the computer.

His advice to students considering manufacturing trades? “I’d advise them to give it a shot,” he says. “It’s really a lot of fun to make parts and if someone has a passion for creating anything, this could be the path for them.” It’s a particularly good fit for those who have a lot of attention to detail, he says.

He adds that even if machining isn’t a good fit, there are many other trades that may be.

His 21-year-old brother Max, for instance, is enrolled in the SMCC electrician program. “I’m incredibly proud of the man he’s become, and I can’t express just how much he means to me,” Henckel says.

But says his advocacy of the trades goes beyond family bonds. “We need more skilled tradesmen and women in almost every industry, and there’s ample pay if you’re willing to put the work in,” he says. “We need more young folks in America to pursue trade jobs.”

0 Comments