Saco’s Mill Brook Business Center is becoming a microcosm of small-business enterprise

Photo / Tim Greenway

Baha LLC developer Dave Smaha, with his partner Anthony Barbano, not shown, responded to high demand and tight inventory in the development of 16 industrial condominiums for small businesses.

Photo / Tim Greenway

Baha LLC developer Dave Smaha, with his partner Anthony Barbano, not shown, responded to high demand and tight inventory in the development of 16 industrial condominiums for small businesses.

Thermoplastic self-bonding ribbon. Ultraviolet light sanitizing machines. Giant abstract public sculptures. Life science product prototypes.

These are some of the enterprising things being produced at the Mill Brook Business Center, a new development of 16 industrial condominium units at 10 Mill Brook Road in Saco.

The center has proven to be a successful draw for a diverse collection of small businesses. That’s just how Portland-based Baha LLC developers Dave Smaha and Anthony Barbano envisioned it.

“I love the variety of different businesses,” says Smaha. “At the end of the day, these businesses own their space. Their payments are similar to what they’d pay on a lease basis, but instead go into their building equity. It’s a win-win situation.”

Reasonable price, opportunity to own

In a tight industrial market where the vacancy rate in southern Maine is about 3%, and whatever is available tends to be sprawling buildings or carved out of vast mills, developers have identified demand from startups and small businesses for smaller industrial spaces that are affordable to own and flexible enough to accommodate a range of uses.

That demand materialized at the Mill Brook Business Center, which in two years has become a microcosm of enterprise that’s even attracting out-of-state startups.

Smaha says he and Barbano designed the center to sell units at an affordable price to small businesses.

“A small-business owner can pay less in acquisition costs and fees than they would pay if they leased, and actually own something and build equity,” Smaha says.

Smaha has been engaged in real estate development — primarily small-residential but also commercial — for the past decade. Barbano owns Elite Construction Services in Saco.

In 2017, they bought 3.7 acres at Saco’s Mill Brook Business Park. The overall park itself is 70 acres located a mile from Interstate 195 and developed with water and sewer access.

Smaha and Barbano developed a plan to build 16 flexible industrial condo units across three buildings. Marketed by Michael Anderson of Malone Commercial Brokers, the units began selling in 2018. Thirteen units have sold and construction of the last three is expected to begin this spring.

Unit sizes range from 1,520 square feet to 3,477 square feet, with 17-foot-high ceilings. Prices start in the mid-$200,000s and go into the $300,000s.

“There’s been a high amount of interest in these units, partially because there’s high demand for flex units,” says Anderson. “There’s a very low amount of inventory.”

“This commercial condo fills a real need,” says Tom Yale, who bought one unit in November and has a second on option. “While popular in other parts of the country, they are relatively new to Maine.”

‘Duct tape on steroids’

Yale was the long-time owner of Yale Cordage, a high-end rope manufacturer on nearby Industrial Park Road, which he sold last July to a private investment group.

Now he’s focusing on a spin-off company, ResinFiber LLC, to manufacture a high-strength, lightweight thermoplastic tape-ribbon called Forj. With a bit of heat, the ribbon molecularly fuses to itself in seconds. Once cooled, the self-bonding plastic hardens, creating a bond as strong as steel, and can be used for repairs for household, outdoor, marine and other uses. The idea is similar to duct tape, but the ribbon can be used repeatedly and it’s much stronger, Yale explains.

“It’s duct tape on steroids,” he says.

Yale and his team launched the product in 2018, when he was still at Yale Cordage. After selling Yale Cordage, Forj remained an interest. Yale searched quite some time for space.

“Mostly I was confronted with having a corner of some much larger space that would have been little less stable than owning a facility,” he says.

He discovered the condo complex by chance.

“I was exploring and they had a sign,” he says.

The size was perfect for racks of inventory and several machines that manipulate extremely strong filaments into fiber bundles, impregnate the fibers with resin, wind the resulting ribbon onto bulk wheels, then feed it into retail-size sleeves and tins. The operation can produce about 450 million feet annually. Recently he had on hand 10,000 tins, each containing 20 feet.

Yale likes being able to share resources with the other owners.

“I borrowed a forklift from one and a ladder from another,” he says. “And I handed out some Forj in return.”

Virus-fighting ‘UVeyor’

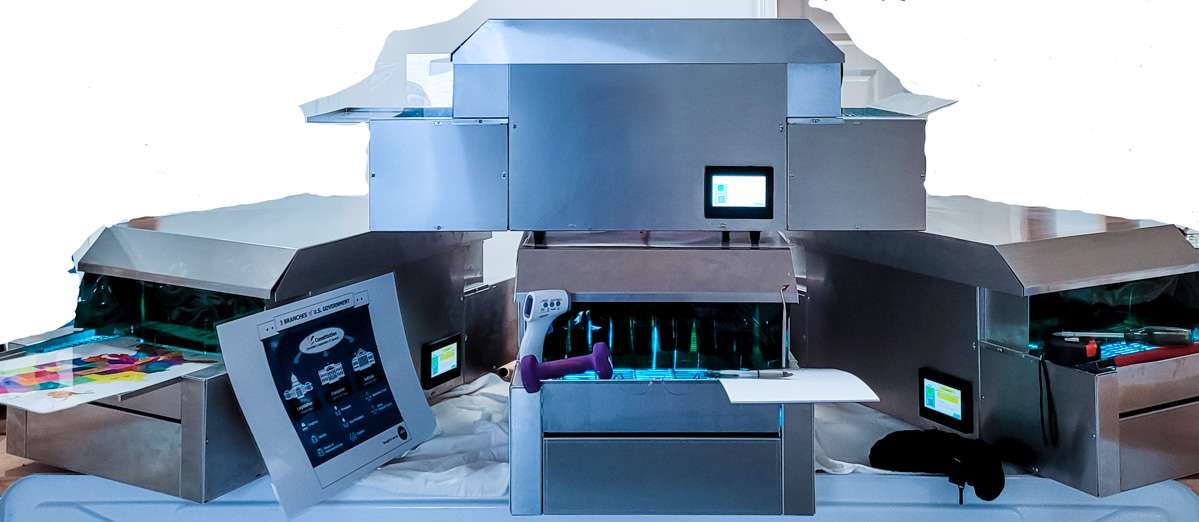

Two units are occupied by the Saco Industrial Innovation Center, where space is available for startups and development is also underway on a virus-fighting ultraviolet light sanitation machine.

The center was established by Kevin Roche, after he sold his Saco-based commercial kitchen equipment maker Belleco Inc. in 2017.

In semi-retirement, he was exploring the idea of supporting manufacturing startups when Smaha and Barbano approached him about their development.

“A lot of people who work out of their garage or have a small mill space can’t afford to rent a 5,000- or 10,000-square-foot facility, let alone own one,” he says.

In response to the pandemic, he and a team led by engineer Erik Goodwin, an employee of Eagle Industries in Hollis who has expertise in fabrication and product design, began developing the “UVeyor,” which uses a conveyor belt to move objects through a housing equipped with ultraviolet light to combat viral surface contaminants like the coronavirus.

The initial phase was funded by Roche’s investment firm, BBK Investments, and Maine Technology Institute. The machine received a 99.99% validation rating that it would kill the virus. Tests are underway at the Biddeford Regional Center of Technology, Roche is seeking other testers and additional funding, while also applying for various permits.

Roche says he expects the technology could be useful for medical facilities, large employers, hospitality businesses and schools.

“In a world where there’s a lot more sanitization of products going on, this will be another tool in the tool box,” he says.

Choosing Saco over Boston

In 2019, product design engineer Trevor Ruggiero moved from Massachusetts to Maine to start up his life science product development company Looma LLC.

It was about choosing affordability and lifestyle.

“We have family here and Maine has the outdoor quality of life we yearned for,” he says. “And the decision to start my own consulting company, and to go after this model with manufacturing, became feasible by moving to Maine because it’s close to Boston — a major medical hub that’s spinning out a lot of technology startups, where this service is well-suited.”

Ruggiero previously spent over 10 years at Woburn, Mass., product development firm Fikst. He identified a need for precise prototyping standards for life science products and liked working with early-stage companies and entrepreneurs developing transformative technology.

Starting on his own last July for phase-one consulting, he soon took on a partner and plans to add precision machining tools for prototype production and early-development problem-solving, with eventual assembly and clean-room capability.

The 2,000-square-foot condo shell he bought was ideal, he says, as an inexpensive, high-bay manufacturing space with three-phase power. He built it out with walls and a mezzanine for a finished space of 3,700 square feet.

“To get something like that in or near Boston would probably cost three times as much,” he says.

Creative fabricator

Nate Deyesso started his business, DSO Creative, in 2004 in Portland. Originally from Massachusetts, he has an art degree from the University of Vermont but moved to Maine when a friend needed help building a kitchen.

“I’ve always loved Maine. So I was happy to end up here,” he says.

Initially he did handyman projects, then grew to custom metal and wood fabrication for commercial clients. Most recently he’s worked on building out retail cannabis stores. But his portfolio includes public sculptures, custom artwork and specialty furnishings.

He was operating DSO, the phonetic spelling of his last name, in a lease.

“We wanted to purchase, but there weren’t any options in Portland, and not really anywhere,” he says.

His real estate agent identified the development just as Smaha and Barbano were getting going.

“We were the first people to move in before the driveway was even poured,” says Deyesso.

Now he and six employees occupy two units, fitted with a plasma-cutting table, a full paint booth, a small wood shop and a large metal fabrication shop.

“We’re mostly cutting and welding – lots of tube steel, flat plate, solid bars,” he explains.

He adds, “I’m lucky this worked out. It was a good price and it’s a great place because it’s positioned near Biddeford and Portland. Portland is the most happening spot and Biddeford is on its way, and there will be more work coming from that region. So this was easy to say yes to.”

Demand continues

For the future? Smaha and Barbano anticipate the start of construction of the development’s last three units. But they’re not stopping there.

“We’re looking for more land in Saco to put up more units because we have so much demand,” says Smaha. “There was a lull for a while: we lost a couple of sales from businesses that were affected by COVID. But now these small businesses are doing really well. We think we have great formula.”

0 Comments