Processing Your Payment

Please do not leave this page until complete. This can take a few moments.

- News

-

Editions

View Digital Editions

Biweekly Issues

- December 1, 2025

- Nov. 17, 2025

- November 03, 2025

- October 20, 2025

- October 6, 2025

- September 22, 2025

- + More

Special Editions

- Lists

- Viewpoints

-

Our Events

Event Info

Award Honorees

- Calendar

- Biz Marketplace

Thomaston boatbuilder develops a high-tech form of personal protective equipment

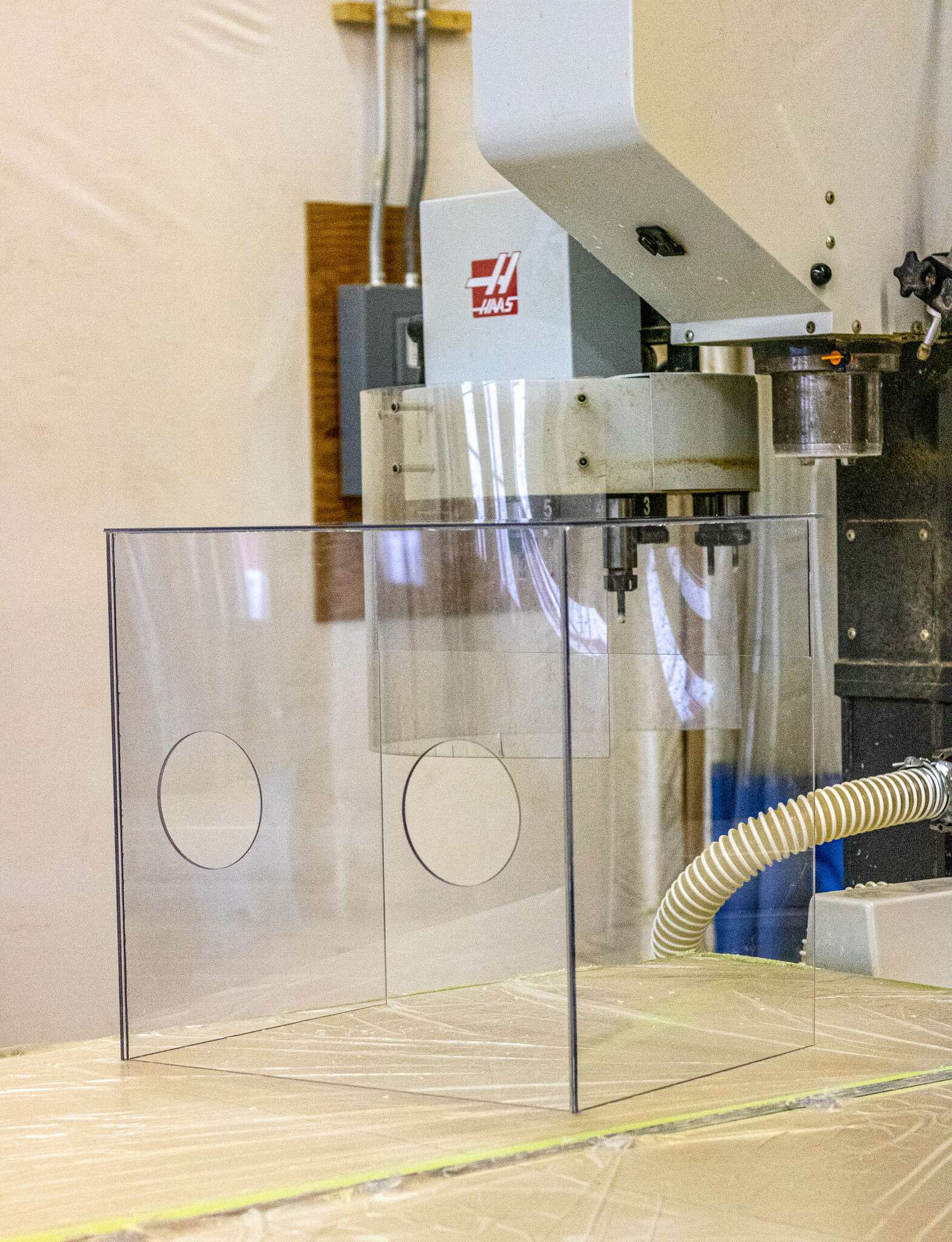

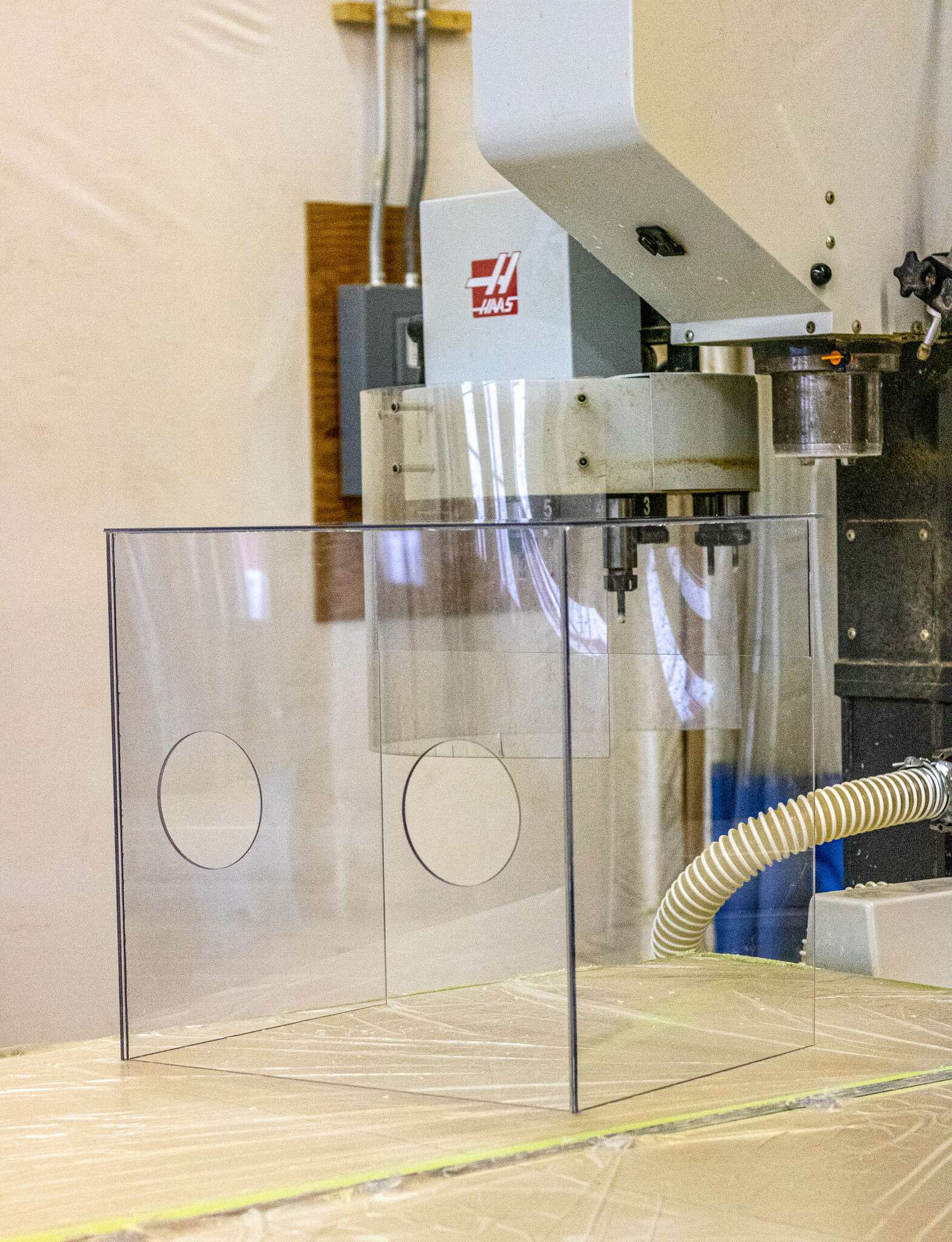

Courtesy / Lyman-Morse

Lyman-Morse's CNC router cuts pieces of an intubation box.

Courtesy / Lyman-Morse

Lyman-Morse's CNC router cuts pieces of an intubation box.

Lyman-Morse, a boatbuilding company in Thomaston, is building personal protective equipment to help combat COVID-19.

The boatbuilder is using its Raise 3D printer to fabricate frames for face shields. The company has specialized business divisions that are also helping.

All of the equipment is being delivered to Lincoln Health Miles Hospital in Damariscotta.

“It makes us feel good to know that we can do something helpful for our community at this time,” Drew Lyman, president of Lyman-Morse, said in a news release. “We are not a mass producer, but as we are all learning, any measure to help can be important.”

The Lyman-Morse Technologies division is building and donating intubation aerosol boxes, which will protect nurses while intubating COVID-19 patients. Another division, Lyman-Morse Fabrication, is building a metal structure for a similar purpose, the company said. The intubation box, from an open-source design originally devised in Taiwan, works by sitting over the head and shoulders of a patient who is being treated.

After Lyman-Morse Special Projects Director Joshua Moore learned of the intubation design, the technology division’s manager, Rob McKay, used Lyman-Morse’s Haas GR712 computer-numerical controlled router to produce the plexiglass box. It acts as a protective shield between the patient and medical staff, reducing their potential exposure to the virus. After each intubation, the box can be cleaned with bleach, an alcohol solution or disinfectant wipes.

Lyman-Morse Fabrication manufactured a metal frame that can be placed over the patient’s head and shoulders and is then draped with protective plastic to form a similar barrier between the patient and the nurse. The fabrication division’s manager, Jonathan Egan, worked with Kevin Houghton, manager of the company’s design division, to develop a simple design that could be easily and inexpensively implemented in hospital rooms.

The company is also using its Raise 3D printer to manufacture frames that hold face shields, an important aspect of health care workers’ protective gear.

Lyman-Morse is a custom and semi-custom boatbuilder and services sailing and motor yachts. A family-run business, it specializes in composites, advanced composites, cold-molded wood and aluminum construction. Lyman-Morse Technologies and Lyman-Morse Fabrication work with architects, interior designers, home owners and government agencies including the Department of Defense.

Mainebiz web partners

Related Content

The Giving Guide

The Giving Guide helps nonprofits have the opportunity to showcase and differentiate their organizations so that businesses better understand how they can contribute to a nonprofit’s mission and work.

Learn More

Work for ME

Work for ME is a workforce development tool to help Maine’s employers target Maine’s emerging workforce. Work for ME highlights each industry, its impact on Maine’s economy, the jobs available to entry-level workers, the training and education needed to get a career started.

Learn More

Groundbreaking Maine

Whether you’re a developer, financer, architect, or industry enthusiast, Groundbreaking Maine is crafted to be your go-to source for valuable insights in Maine’s real estate and construction community.

Learn more-

The Giving Guide

The Giving Guide helps nonprofits have the opportunity to showcase and differentiate their organizations so that businesses better understand how they can contribute to a nonprofit’s mission and work.

-

Work for ME

Work for ME is a workforce development tool to help Maine’s employers target Maine’s emerging workforce. Work for ME highlights each industry, its impact on Maine’s economy, the jobs available to entry-level workers, the training and education needed to get a career started.

-

Groundbreaking Maine

Whether you’re a developer, financer, architect, or industry enthusiast, Groundbreaking Maine is crafted to be your go-to source for valuable insights in Maine’s real estate and construction community.

ABOUT

NEW ENGLAND BUSINESS MEDIA SITES

No articles left

Get access now

In order to use this feature, we need some information from you. You can also login or register for a free account.

By clicking submit you are agreeing to our cookie usage and Privacy Policy

Already have an account? Login

Already have an account? Login

Want to create an account? Register

Get access now

In order to use this feature, we need some information from you. You can also login or register for a free account.

By clicking submit you are agreeing to our cookie usage and Privacy Policy

Already have an account? Login

Already have an account? Login

Want to create an account? Register

0 Comments