UMaine’s advanced capabilities advance companies and workforce for the 21st century

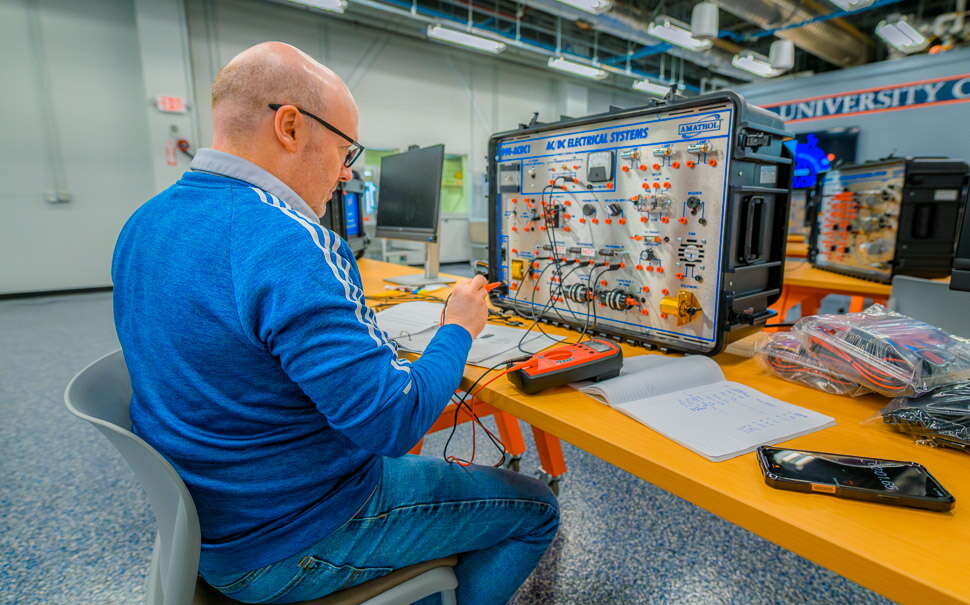

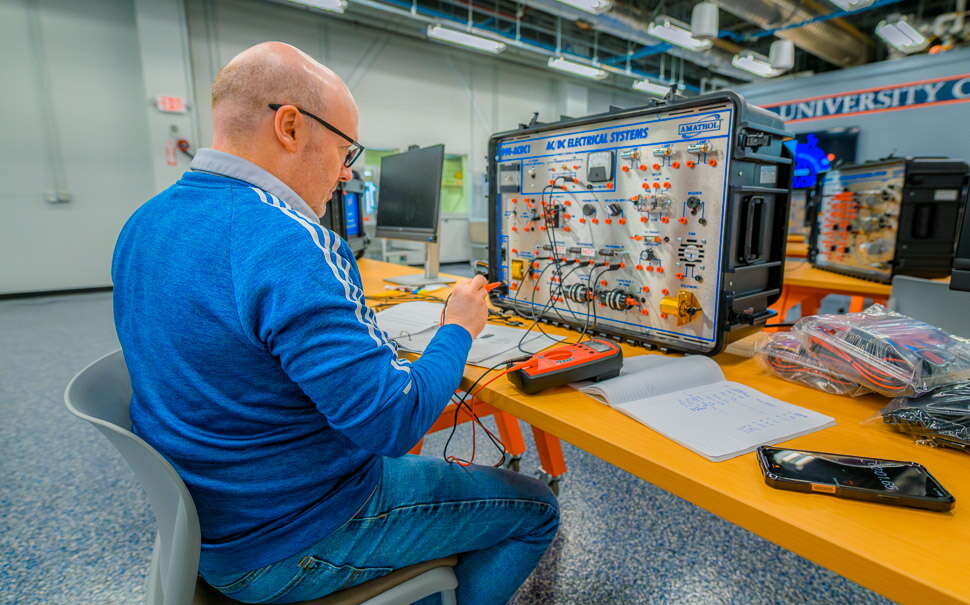

Photo / Jim Neuger

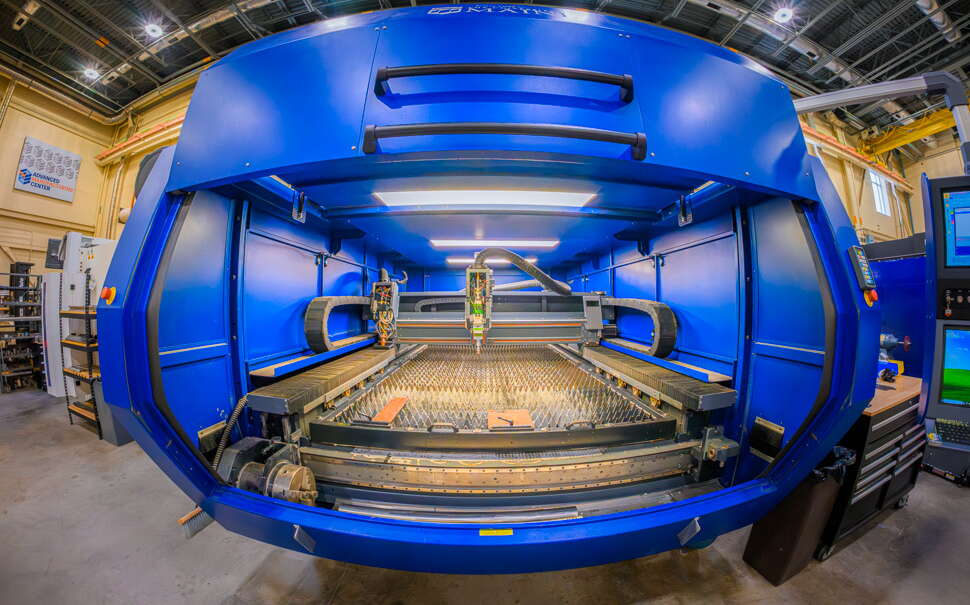

Members of the management team of the University of Maine’s Advanced Manufacturing Center in Orono, in front of a laser cutting machine. From left: Brad Denholm, associate director of workforce development; John Belding, director; Forest Wentworth, associate director of projects.

Photo / Jim Neuger

Members of the management team of the University of Maine’s Advanced Manufacturing Center in Orono, in front of a laser cutting machine. From left: Brad Denholm, associate director of workforce development; John Belding, director; Forest Wentworth, associate director of projects.

Over the past decade, Compotech in Brewer has moved from manual production to automated systems that integrate robots to create ballistic protection systems and expeditionary shelters for U.S. Army troops.

The Advanced Manufacturing Center at the University of Maine in Orono has been instrumental in helping Compotech automate its process for tasks such as sanding, drilling, welding and packaging.

Primarily a defense contractor, Compotech has about 80 employees at its manufacturing facility in Brewer and its digital solutions site in Orono. Making thousands of armor panels a year, automation throughout the production line has improved quality control and efficiency.

“They helped us build manufacturing equipment for our facility,” says Paul Melrose, the company’s president. “For example, they helped automate the process for making some of our armor panels, making it easier for the operators to perform tasks consistently and efficiently — a human-machine interface, so to speak.”

Concept to production

Founded in 2002, the Advanced Manufacturing Center has worked with hundreds of companies and trained scores of students. The engineering support and service center helps move ideas from concept to production through hands-on prototyping, design and fabrication services for companies across Maine and provides workforce development programs.

These days, the center is leading companies and students into the future of “Industry 4.0,” a term that refers to digital advancements such as the integration of artificial intelligence into manufacturing processes. The center recently opened a robotics and automation workforce training facility called the B.O.T. Loft (build, optimize, train) equipped with collaborative robots (cobots) and automation trainers.

“Based on recent studies completed by the AMC and partners, having a cohort of trained operators and technicians is essential to help company managers develop the confidence to embrace automation and robotics,” says John Belding, the center’s director. “The B.O.T. Loft is the next stage in the AMC’s longstanding commitment to help companies trial and de-risk the adoption of these technologies, and to train workers with the skills needed to operate them.”

Bandsaws and robots

The center started in 2002 to support manufacturing around Maine. The 30,000-square-foot building where it’s housed was completed in 2004. Today, the building houses $6 million worth of equipment and a staff of eight, most coming from industry, who work with startups, small businesses and established manufacturers through prototyping, design and fabrication. The center provides applied learning experiences for undergraduate and graduate students and for professionals.

Programs include micro credentials, factory-authorized training, college and high school hiring and even a high school summer camp built on a cobot curriculum that resulted in programmer certification.

“It’s a great opportunity for a high school student who’s interested in engineering to get a real taste of what engineering and what working in manufacturing is like,” says Forest Wentworth, associate director of projects.

There are precision CNC machines, fabrication labs, prototyping capabilities and cobots. Large multi-axis machines can cut parts from all directions. Three-dimensional printers are equipped with spools of plastic, plant-based and metal materials in climate-controlled cabinets. There are laser scanning, cutting and welding systems; a press brake that bends hefty pieces of metal like butter; and the type of equipment — bandsaws, table saws — common to any workshop.

Projects recently on the shop floor include a machine that speeds the production of catnip pouches for a specialty company. Bales of catnip and colorful pouches await tests near a machine that includes a hopper, dosing head and auger. Instead of manually filling the bags, the company can fill the hopper, put the pouch under a nozzle and step on a pedal.

“They wanted assistance figuring out what type of equipment to buy and help them set it up,” says Belding.

Work is underway to update a mechanized blueberry raker and a machine that staples bags to collect farmed oysters. A small machine shop in Bangor tapped the center’s laser-cutting capabilities to cut parts.

Long-time partnership

Early in their relationship, the center assisted Compotech in transitioning from the manual production of armor panels, with thousands produced each year, to an automated process.

“It speeds production. It optimized the cycle time, from when we load in the panels until we take final product out,” says Melrose. “The automated computerized process allowed our engineers to identify where we could reduce cycle time on different steps to increase our factories output. The system does an excellent job logging and maintaining production data for our factory.

The center worked with Compotech to design the automation systems, built with off-the-shelf components, along with custom components designed and built by the center.

More recently, Compotech is using the B.O.T. Loft to train computer programmers and engineers in its digital solutions business unit on how to integrate Compotech’s inspection software with industry standard robotic capabilities.

“AMC has been a long-time partner with us — really, since we started as a company” in 2011, says Melrose. “Even if it’s just giving them a call, asking them some advice on a particular equipment purchase or helping us with a project.”

Updated lathe

Two years ago, Neil Gutekunst and his wife Jennifer bought Shaw & Tenney, a maker of traditionally handcrafted wooden oars, paddles and poles dating back to 1858.

Within a week of buying the company, Gutekunst made a call to UMaine to continue a project, begun under Shaw & Tenney’s previous owner, to see if a lathe from the mid-1900s could be revamped. The project would include developing new components, adding a variable frequency drive and a safety guard.

The overhaul, including the addition of a sander in the same operation, would reduce the amount of time it took to produce an oar shaft, with its distinctive square-to-round shape, from one in 30 minutes to four in 12 minutes.

The result is increased capacity, both for premium made-to-order products and for utility stock that has since launched, under the brand name Woodland Oar and Paddle, at a lower price point through business-to-business deals.

The center is also assisting with the prototype for an axe handle, a more complicated pattern, as part of a partnership between Shaw & Tenney and South Portland hand-forged axe-maker Brant & Cochran.

Gutekunst calls the relationship with the center “a real collaboration.”

“Luckily we were nearby because they were back and forth,” he says of the center’s staff willingness to travel. “We have a graduate of the UMaine engineering school who worked here and was able to produce drawings of the pattern. They cut the steel to make the pattern, we bring it back, sometimes it just needs tweaks, we test it, they remake it. Now we’re turning oars.”

Student involvement

About 20 undergraduate and graduate students work at the center each year. They’re trained on the equipment and work on specific projects.

In the center’s student lab, Ean Canfield, a sophomore majoring in mechanical engineering, is working with a computer-assisted design program to refine a paper-cutting machine. His screen shows renderings of “hard stops” that make it easier to position the paper. A simple computer instruction sends the design to a 3D printer for prototyping.

Daniel St. John, a junior, has been working on improvements for the blueberry harvester.

“We’ve completed the first round of testing and gone back to the client,” says St. John, who came up with some of the concepts and worked directly with the client, under the supervision of his project manager.

It’s exciting to work on solving complex engineering problems, he says.

“You have an idea in your head and you can make it — you’re creating things,” St. John says. “I really like that.”

Industry roots

The level and breadth of technologies in one shop and available to industry as a whole makes the center unique, says Wentworth: “You might see all of the pieces of equipment in a handful of machine shops, but not put together, not all in one shop, unless it’s, say, an aerospace shop or a defense shop.”

Also unique are the staff’s roots in industry, he continues.

“We might be at an academic facility here at UMaine, but we’re from industry first,” Wentworth says. “We all worked in manufacturing, typically for a decade or more before coming here. So, we bring our experiences, from running manufacturing floors to being technicians, fabricators, manufacturing managers, professional engineers, to running our own companies. We bring that all to this center.”

Recently, the center had 30 active projects underway.

“We’ll finish between 20 and 50 projects per year,” he says. “They can be $500 to $100,000 projects and anywhere in between.”

Counting advisory meetings along with project contracts, the center sees up to 100 clients each year.

“It always starts with a conversation,” says Wentworth. “Someone comes to us and says, ‘I have this idea to make X, Y, Z.’ I say, ‘Okay, let’s talk about what your project needs in order to get to what you define as a success as a client.’”

Workforce development

The center’s workforce development efforts resulted from industry demand, says Bradley Denholm, associate director of workforce development.

“There was a clear need not only for more workforce in Maine but for a higher-skilled workforce, able to work with the latest technologies,” says Denholm.

Most Maine manufacturers operate at the “industry 2.0” level, meaning they have mechanized mass production capabilities. Some are industry 3.0; they’ve brought computers, automation and robotics into their processes.

Industry 4.0 leverages the integration of 3.0 systems across production and information management systems, along with data analytics and machine learning to optimize business processes.

The center’s training program is flexible, designed for industry newcomers eager to learn the basics just as much as long-time professionals looking to be up-skilled.

“We have a lot of equipment and are set up to train in a flexible manner,” says Denholm. “That makes the program open and applicable to anyone, whether you’re an incumbent worker — say, an electrician or technician — and that organization wants to start bringing on robotics and automation, and that individual needs upskilling. We’re able to support those folks.”

At Compotech, Melrose considers the center invaluable for the industry: “By having all of the Advanced Manufacturing Center’s resources right there, it’s a great asset for the state of Maine.”

0 Comments