A Maine manufacturer helping small businesses: Pieceworks handles a range of production

Photo / Fred Field

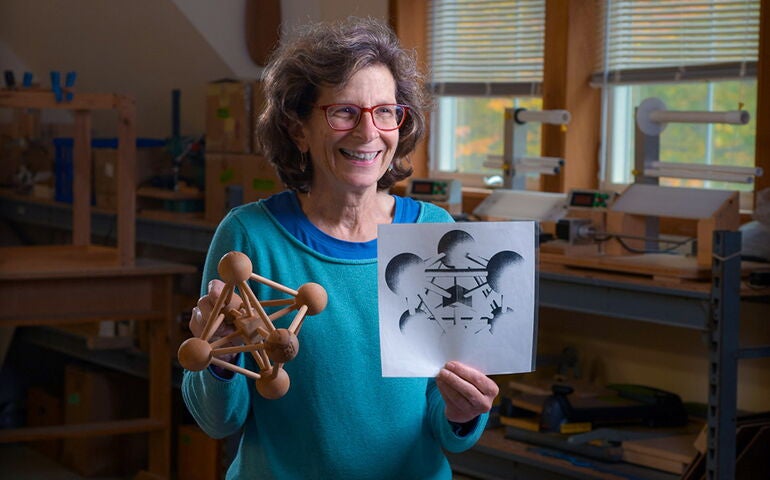

Pieceworks, a contract manufacturer in Montville, is owned and operated by Cathy Roberts. She’s holding a promotional model her team engineered for a software company from a drawing the company provided.

Photo / Fred Field

Pieceworks, a contract manufacturer in Montville, is owned and operated by Cathy Roberts. She’s holding a promotional model her team engineered for a software company from a drawing the company provided.

Hidden away in the rolling hills in Montville, Pieceworks is a two-story structure set back in the woods. It may appear quiet, nestled in the woods, but inside machines are humming, employees are busy and boxes are being packed for shipping.

The family-owned manufacturing business is owned by Cathy Roberts.

Pieceworks offers contract manufacturing and assembly services to entrepreneurs, filling a need in Maine and across the region. Pieceworks bridges the gap for other small businesses by providing creative and custom solutions to streamline and scale up their manufacturing and production challenges — with a focus on sustainability, made-in-Maine quality and keeping jobs in the state.

This primarily involves light manufacturing, assembly, packaging and shipping but can also include R&D for new products.

“Pieceworks has always been described as a custom contracting business, which implies that we offer a diversified opportunity for different kinds of businesses to take advantage of our services,” says Roberts. “It’s our customized and tailored approach, with our versatile, reliable, and skilled team, that I feel separates us from a traditional manufacturing company.”

Clients range from a company that sells heated stadium seat cushions to health care providers that need custom name badges.

How it started

Roberts’ interest in manufacturing began when her late father, Ken Roberts, an entrepreneur and inventor, needed a supervisor for his companies, GemSet and Harbour Galleries in Rhode Island.

He created an international grading system for colored stones because, in the jewelry business, he found that it was impossible to keep all the gemstones categorized for customers.

Roberts managed the technical assembly, quality control and international fulfillment from her home in Maine. Roberts worked for the company for several years until it was sold in 1995.

“When my parents sold the business, the employees came to me and said, ‘We’ve done this great product that was shipped internationally and required immense quality control, because it was an international system accepted by the Gemological Institute of America,” says Roberts.

“It set up a situation where the employees said, ‘Go find us more work and we will stay.’ And we could do assembly for other businesses — and that’s how we started.”

After the business was sold, Roberts entertained the idea of creating her own business. At the time, she had three young children and was interested in remaining self-employed, ideally working from home. She started Pieceworks in 1996 in a room in her Montville house. In 2006, she moved into a manufacturing facility she and her husband built in Montville.

Roberts has five full-time employees who have been thoroughly trained in every aspect of the business.

Behind the scenes is Roberts’ husband, Cam Pierel, owner of Liberty Cabinet & Design, a woodworking shop in Montville. Pierel is known as the production engineer. Throughout the building, he has made wooden jigs for different machines, which help assemble or manufacture a product.

“We work with a science education company. There are over 100 products we do for them,” says Roberts. “One of them is this pipe; we get them already cut, and we drill two holes into them, then we have to put screw eyes into them, and we have to open the screw eyes to a certain distance. We can’t buy them the distance they want so we had to create a jig for this product.”

“Being a woodworker, most of the jigs he makes for us are wood, but he comes up with these interesting jigs used for different products,” Roberts says of Pierel. “He keeps looking for ways to save our clients money and he helps us to be as efficient as possible.”

Roberts works with 12 clients in and out of the state.

“I have to say that I have not marketed really at all. This is a business that has been built on word of mouth,” says Roberts.

The company has working relationships with Maine Technology Institute, Coastal Enterprises Inc. and Maine Manufacturing Extension Partnership.

“They all know about me and so occasionally, clients will come my way through them,” Roberts says.

How Pieceworks works with clients

One client is Southport-based Hüga Heat, which sells battery-powered heated seat cushions.

The product was created by a couple, Jocelyn Olsen and Colin Greig, in the early days of COVID-19, when outdoor dining and socializing became part of the limited social gathering taking place.

Olsen and Greig realized there were few cushions on the market that could stand up to the outdoor conditions. They tested and prototyped cushions that they felt could handle daily outdoor use. The developed a cushion that could be wiped down with sanitizer and still look and feel good, go strong for many seasons and for many hours.

To provide warmth, the cushion was outfitted with a battery that could run for 10 hours, even on the high setting in low temperatures. It also seemed like a marketable product for outdoor sporting events, but also hockey games — which are even chilly indoors.

The name Hüga comes from the Danish term “hygge” (pronounced hyoo-ga) which means creating a warm atmosphere and slowing down to enjoy the good things in life with good people.

“For the first two years in business, I was hand-stuffing every cushion we sold,” says Olsen. “It required a huge investment of time that I couldn’t dedicate to managing and growing the business, not to mention the tennis elbow that was starting to flare up. One of our company’s founding tenets was that we want to reinvest our spending in the Maine economy whenever possible, so we searched for a contract manufacturer in Maine instead, which is how we found Pieceworks.

“With some experimentation, [Pieceworks was] able to find a better way to stuff the cushions that do not strain their team’s arms and hands and is significantly more efficient than the way we were doing it,” adds Olsen. “Taking that fresh perspective and listening to what matters to us allowed them to evolve our process in a way that works for all of us.”

Name badges

Initial This Inc. is a Bangor-based company that manufactures retractable ID badge reels and keychains with over 400 designs. Its customers are primarily shops that sell health care worker scrubs.

Owners Jack and Lisa McDonald have been working with Pieceworks for almost a decade.

In 2014, Jack McDonald contacted Roberts about contracting out the manufacturing part of his business to Pieceworks. In a call, Roberts said she was about to leave for vacation. McDonald told her that he would be up there in three days and urgently packed everything for a move to Maine.

This is like many businesses around the state that are having difficulty finding and training employees. McDonald said that recruiting takes time away from focusing on the business itself.

“This is a situation where [Pieceworks] would be dealing with the employees,” says McDonald. “Hiring someone isn’t easy. Having employees oversee manufacturing would build up a lot of my time and having to find employees means I would have less time to build the business.”

McDonald says Pieceworks takes the same approach to sourcing.

“Every piece of the product is 100% made at Pieceworks. Products are sourced from U.S. brands. Roberts and her employees put the pieces and prints together. They have all of our printers and equipment,” he says.

What’s next

While Pieceworks is still very much a small business, Roberts says she is eager to expand the business and take on more clients, with limits.

“I have people asking for work all the time, but I am not looking to hire more people at this time,” says Roberts. “I am not looking to have 50 employees.”

“I would hire more to accommodate more work, which is what I am interested in,” she adds. “If I doubled, that would be exciting. There is a comfortable point of gradually increasing, and I see the need now after the history I’ve had. Manufacturing is so widespread in so many different areas. People talk more now than ever of bringing manufacturing back to this country or back to Maine.”

0 Comments