Biocarbon processing plant plans to locate at East Millinocket mill site

Courtesy / SBC

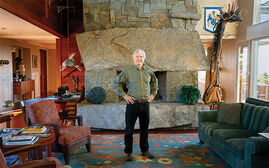

A biocarbon processing plant, similar to this one, has signed on to locate at the East Millinocket former Great Northern Paper mill site.

Courtesy / SBC

A biocarbon processing plant, similar to this one, has signed on to locate at the East Millinocket former Great Northern Paper mill site.

A new Maine company plans to build a plant that will sequester carbon from Maine forests at the former Great Northern paper mill site in East Millinocket.

Standard Biocarbon Corp. has signed a letter of intent with the East Millinocket Industrials Inc. board of directors to site a pyrolysis plant at the former mill site. If completed as planned, the plant would convert low-grade biomass into biocarbon, the carbon component of wood.

The company said in a news release it's the first step in establishing biocarbon as a viable sustainable forest products industry in Maine, one that will also help cool the planet.

The plant will use low-grade wood traditionally harvested for paper making or power generation to produce biocarbon, sold commercially as “biochar” and currently used in agriculture and environmental remediation. No information was immediately available on the size of the proposed SBC production plant, the timeline or how many jobs it would create.

The company would be the first major tenant at 215-acre former mill site, which the town acquired for $1.45 million last year, with plans to develop an industrial and innovation park, with a focus on emerging forest-industrial use.

The company filed for incorporation in November and was incorporated Jan. 31. It's intention when it formed was to open a biocarbon sequestering plant this year, according to its website.

Fred Horton, a Portland native who has spend four decades in finance, is CEO and president; Tom Horton, also of Portland, an environmental developer, is COO. Advisors include IDEXX founder David Shaw, as well as Bob Saul, an agriculture and forest industry investor; inventor and investor Ramin Abrishamian; and Phillip Barach, cofounder of DoubleLine Capital.

'Plans to be leader in new industry'

Since 2014 Maine has lost markets for 4.3 million tons of low-grade forest products as paper mills and biomass power plants closed. "Biocarbon extraction from wood offers a new and viable means to sustainably use Maine’s vast working forests and wood products infrastructure to grow Maine’s economy, and create jobs in an environmentally friendly manner," the release said. "Standard Biocarbon plans to be the leader in this new industry for Maine."

The mill site "offers a vastly scalable, stable feedstock supply with the same fundamental efficiency advantages it afforded Great Northern Paper in an earlier era," the release said. "It takes five tons of wood to produce one ton of biochar — the East Millinocket location close to this feedstock is critical."

Production lines would be added as production is scaled to meet demand, SBC said. Excess heat from the plant can also heat buildings on site and will be offered to energy-intensive tenants as an incentive to locate on the former mill site.

Biocarbon, with properties similar to activated carbon, improves soil productivity, reducing the need for irrigation and fertilizer. It’s also an alternative to mined peat moss. And because biocarbon binds with heavy metals, phosphorus and other soil and water contaminants it can be used in environmental clean-up.

"Importantly, biocarbon is an important tool in fighting global warming," SBC said in the release. SBC's pyrolysis process will permanently remove carbon from the atmosphere that would otherwise be released through combustion or decomposition. Biocarbon is chemically stable and persists for hundreds of years in the soil. One ton of biocarbon locked into the soil equates to about 3.5 tons of carbon dioxide being permanently removed from the atmosphere.

SBC expects to certify that it has permanently sequestered approximately 10,000 tons carbon dioxide in the first year of operations, the company said.

0 Comments