How a Winter Harbor man found success in barbecue spices with Maine ingredients

Courtesy / Bub 'n Mutha’s

The new Bub 'n Mutha’s space in Ellsworth is twice the size of its previous digs in John Fuhrman’s kitchen.

Courtesy / Bub 'n Mutha’s

The new Bub 'n Mutha’s space in Ellsworth is twice the size of its previous digs in John Fuhrman’s kitchen.

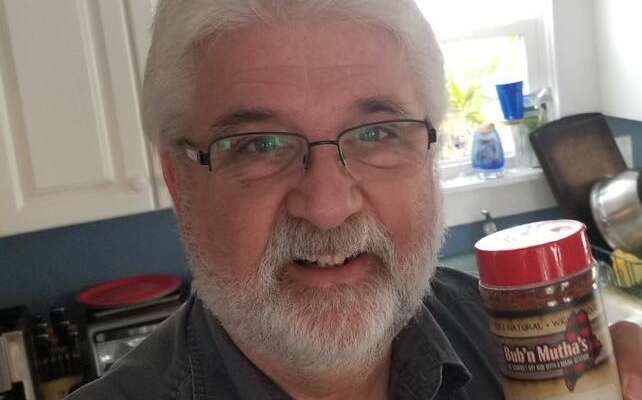

John Fuhrman owns Bub ’n Mutha’s, a Winter Harbor producer of barbecue dry rubs.

He recently expanded his production space after taking home the judge’s top prize in the second annual Downeast Business Bootcamp Pitch Off.

Founded in 2018 with its DownEast Dinnah Dust, Bub ’n Mutha’s products use natural spices and ingredients from Maine companies like Raye's Mustard, Maine Maple and Coffee Hound, can be found today in over 71 stores in seven states.

Recently Fuhrman partnered with NASCAR team Josh White Racing as an associate sponsor to raise brand awareness.

Fuhrman's website credits “Mutha” for her production of “wicked good food.”

It would be natural to assume he’s referring to his mother.

That assumption would be incorrect, as Mainebiz discovered. We asked Fuhrman about his startup journey and plans for the future.

Here’s an edited transcript.

Mainebiz: What did you do before Bub ’n Mutha’s?

John Fuhrman: I was born in Winter Harbor and raised outside of New York City, where my dad was in the U.S. Navy. I got into the auto industry and lived in New Hampshire, New Jersey and North Carolina, which is where I learned barbecue.

MB: What did you do in automotive?

JF: I started out selling cars, grew into management, then ultimately got into the industries that supported the car business.

MB: What brought you back to Winter Harbor?

JF: I had the chance to come up and help a dealership. But once I got here, it was more — if I’m going to stay here I want to do something radically different. Wouldn’t it be odd to live in a lobster village on the coast of Maine and make barbecue products?

MB: So who is Mutha?

JF: It’s a story. That was literally put together over a notepad and beer, thinking about the absurdity of making a dry rub in a lobster village on the coast of Maine. We had to come up with a cute but outrageous story.

MB: And we can presume you’re not Bub?

JH: Bub and Mutha are fictitious. To build the brand, we’ll continue to build their legend, and have them as characters.

MB: It sounds like you had the basics of making dry rub from your time in the Carolinas. How did you develop that to include Maine ingredients?

JF: I went on Google and said let’s see all the Maine food companies out there. I made a short list, got in my truck, drove from Winter Harbor to Eastport, walked into Raye’s Mustard, met Karen Raye and said, ‘I have an idea.’ They agreed to supply us with their ground mustard for our rubs. We shook hands, I drove back and said, ‘Okay, now I’m a Maine company.’

MB: You keep saying ‘we.’ Do you have partners or employees?

JF: It’s just me.

MB: How did the recipes continue to unfold?

JF: Most rubs, especially from the South, are brown-sugar based. There’s an element of sweetness that takes the edge off the heat and makes the meat caramelize better. I started thinking, ‘What can I use instead of brown sugar?’ The first answer was maple crystals and we went to Maine Maple [Products] in Madison. Then we added blueberry powder to our Dinnah Dust. We added coffee from Coffee Hound [Coffee Co.] in Brewer — they roast an espresso for us that they grind specifically for our rubs.

MB: How did you test the products?

JF: I gave it to a few chefs around the country and said, ‘Just try it.’

MB: How did you know the chefs?

JF: One was a college friend of a friend. From there, that chef introduced me to other chefs. Then one chef said, ‘Can I get some more?’ So I knew it tasted good.

MB: How did you roll it out from there?

JF: We made 24 bottles of each flavor, got in the truck and started driving the coast, south a little bit, then north a little bit. Our pitch was the same — ‘Will you take these home and cook with them? If you’ll do that, then I’ll talk with you in a week.’ We finished 2018 with eight stores; seven were seasonal. We sold 400 to 500 bottles and made just under $2,000 gross.

MB: Were you doing this in your kitchen?

JF: Yes, we had boxes and boxes and boxes of ingredients and packaging. That first year our label was created on my computer. I had to go and search for the size and shape of the bottle I wanted. When we found those we ordered a couple of hundred. We had eight stores and we were trying to take a case of each flavor to them, so that’s 16 cases.

In the beginning, they said, ‘What are your terms?’ I said, ‘I have no terms.’ I said, ‘Our first orders are COD, and because we’re just getting going, I won’t charge you shipping. I’ll deliver it myself.’ All of that was to conserve money, so that when I collected their checks, I was able to reorder ingredients and supply the next few stores.

MB: What did things look like your second year?

JF: In early 2019, Renys came onboard. The business they gave us was phenomenal. For me as a company, that was validation.

MB: How did you get Renys?

JF: Networking. I got the name of their buyer. I couldn’t get him on the phone so I took a chance. All of Renys’ email was patterned the same way. I took a guess that his would be patterned the same way, too. I typed the email and luckily it went through. I said, ‘We’re a Maine-based barbecue company in a lobster village.’ He responded almost right away — ‘I’m in the middle of year-end, I’m not talking with anyone until February.’ I emailed back and said, ‘I’ll call you in February. But in the meantime, can I send you our rubs to take home and try?’ He’s, like, ‘Yeah, fine.’ Not only did I not bother him, I didn’t bother to write down when I needed to contact him again. All of a sudden I look at the calendar and it’s March 2. So I sent him an email going, ‘Hey, just checking in, did you ever get my samples?’ I hadn’t even left my computer when his reply came through. It was literally one line — ‘Got ‘em, tried ‘em, loved ‘em, send me your cell number, we need to talk.’ That first order was, like, 50 cases.

MB: What happened when the pandemic hit?

JF: We started to do online retail more seriously. In 2021, we continued to market and started getting more stores signing with us.

MB: How did you start reaching stores outside of Maine?

JF: Email blasts. We’d do searches. We don’t belong in big supermarket chains, where people are not necessarily creating a recipe for each meat they’re buying. Where we do well is in gourmet stores, meat stores, seafood shops — where the customers are having conversations with someone who knows what they’re talking about. I don’t want to be everybody’s spice. You can get [brand-name spices] from $2.50 to $3. Ours are $6.99.

In 2021, we also signed on with a barbecue subscription company, like the ones you see on TV. One of their orders equaled all of our 2019 revenue.

MB: What’s the cost of making your product?

JF: A thousand pounds of our base mix — paprika, garlic, onion, pepper, cumin, salt — with shipping costs about $3,500. A hundred pounds of blueberry powder — that’s about 10% of our ingredients — costs nearly $5,000. Maple crystals are $10 per pound. Mustard is about $10 per pound.

MB: What’s your profit margin?

JF: It depends on the store. Anywhere from 30% to 55%, or 70% doing online retail.

MB: How did you finish 2021?

JF: We finished the year with 60 stores from Maine and Florida. Most are in Maine. For the year, we did 30,000 to 40,000 units.

MB: How is 2022 looking?

JF: Already in Q1 2022 we’ve added 11 more stores. We’re looking to ramp up to about 4,800 cases, which will be about 80,00 to 90,000 units. Wholesale, we’re hoping to top a quarter millions dollars.

MB: You recently moved out of your kitchen to a new space at the Union River Innovation Center in Ellsworth. Tell us about that.

JF: It doubles my space and allows me to be more aggressive in filling orders. We can probably do 400 to 600 cases per month, as opposed to half that. We’ve got a bunch of shelving units, a stainless steel mixing table that we didn’t have before, big sinks for cleaning, moved in our mixing equipment and can probably warehouse several hundred cases of finished product here.

MB: Is it still just you?

JF: It’s still just me. But within the next couple of weeks, we’ll reach out to our friends at the Maine Veterans Project [a Bangor nonprofit offering programs and services for Maine veterans]. Our goal is to create full-time positions for area veterans.

Mainebiz web partners

Great job John. We ❤️ The rub samples you sent. Not at all surprised with your success !!

1 Comments