Brewer manufacturer of dryer systems doubles space, expands product line

Courtesy / Nyle Systems

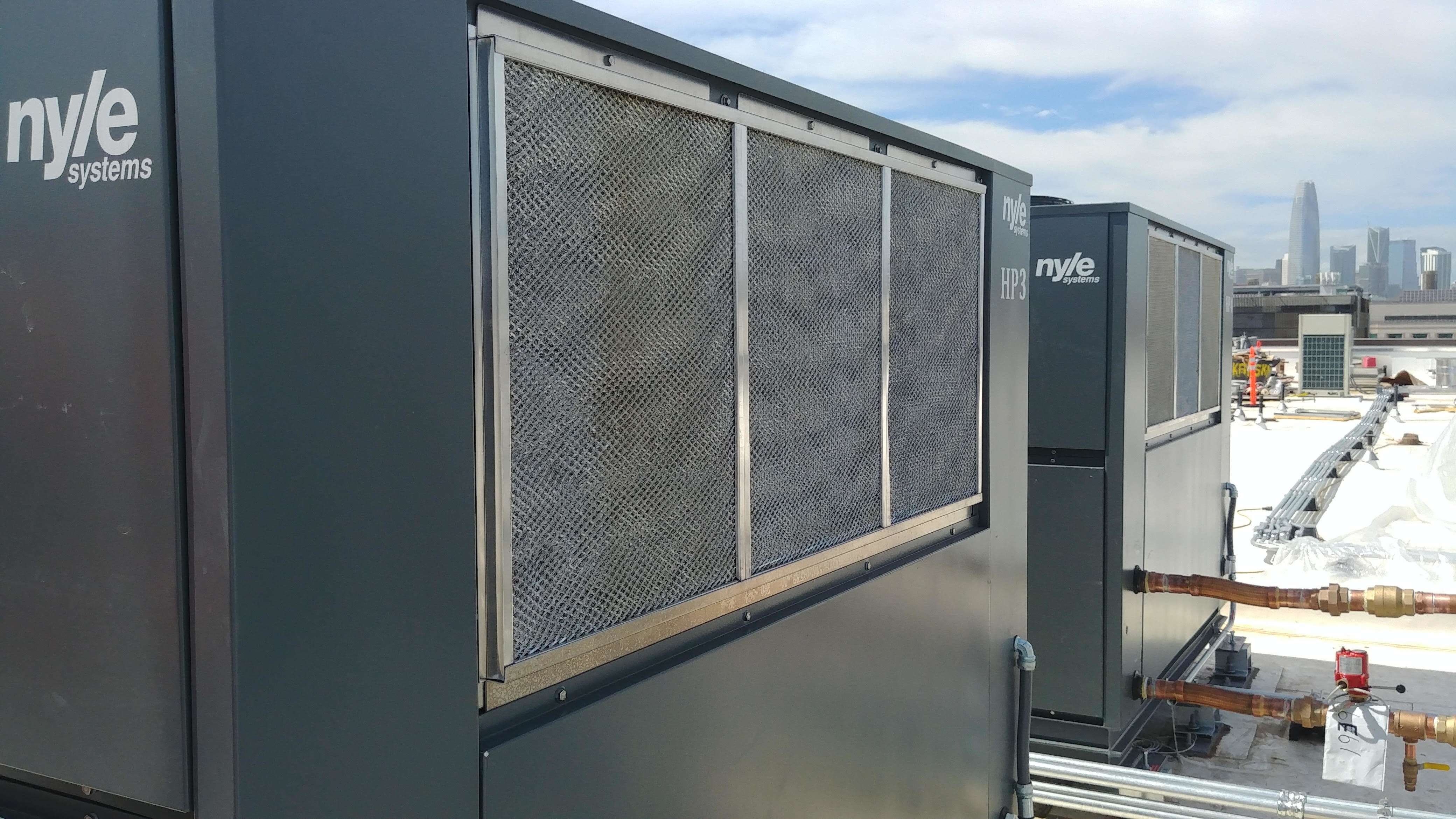

Most components for the container food dryer, including this air ducting, are manufactured at Nyle Systems' factory in Brewer.

Courtesy / Nyle Systems

Most components for the container food dryer, including this air ducting, are manufactured at Nyle Systems' factory in Brewer.

A Brewer manufacturer that specializes in industrial dehumidification systems is in the midst of doubling its production space and expanding its product lines, including a new industrial-size “container food dryer” system for human and pet food.

Nyle Systems develops, manufactures and sells heat-pump-driven equipment for lumber drying, food dehydration and water heating.

Its latest container food dryer system includes a dehumidification unit, air handling equipment and temperature controls, all designed to produce human and pet food with specific characteristics such as color, texture and nutrients. The system is built inside re-engineered shipping containers.

“We’re ramping up and seeing an increase in that business as we look to expand our marketing efforts,” the company’s vice president, Eric Long, told Mainebiz.

Last fall, Maine Technology Institute awarded the company $142,981 toward a total project cost of $677,950 to double its production space, increase efficiencies and enhance new product development capabilities, according to a news release. The company has 55 employees and plans to hire more.

The pre-fabricated drying system is designed to be modular and easily moved around a facility. Digital technology and a tight, closed-loop container chamber is designed to allow a customer to create the conditions for the food being dried. A touch screen and remote control access provide real-time data for temperature, relative humidity and air speed.

“The idea is to leverage our strengths, which is drying foods at relatively low temperatures and controllable humidity,” said Long.

For example, products that dry slowly at low temperatures usually maintain their vibrant color, he explained.

Nyle sold nine systems, one of its larger orders, to an overseas customer last year seeking to dry agricultural products. A customer in Canada recently purchased a dryer to dehydrate seafood.

Drying equipment has also seen a spike in demand in the pet treat sector; a system was recently shipped to a Midwest producer of jerky treats. Another system went to a Sunderland, Mass., producer of chili-pepper products that has experienced skyrocketing demand at natural food grocers across the Northeast.

The company also has customers in Maine and is seeking to expand that customer base, Long said. A typical entrepreneurial customer is a Kittery-based Good To-Go, which makes dehydrated outdoor-use gourmet meals.

More production space

Founded in 1977, Nyle Systems moved to its current headquarters in 2010.

Occupying half of a 56,000-square-foot warehouse, it has expanded over the past decade from manufacturing heat pumps to finding applications for its technology in lumber drying and residential water heating,

The revamped production space will include a test chamber for new product development, a food drying test laboratory and a larger paint room. Additional renovation includes installation of electrical and gas lines, installation of an air ventilation system for an expanded welding department and remodeling the offices to accommodate a growing workforce.

Aggressive targets

In a separate phone interview, Nyle’s CEO, Ton Mathissen, said the company has grown its workforce from a dozen people in 2010 to about 55 now. It’s currently conducting interviews for two positions and it frequently hires across a number of functions, he said.

Some long-tenured employees have been with the company 20 to 30 years or more, he added.

The company has doubled its revenue about every three to four years and expects to continue that rate of growth, he continued.

“If you think about us doubling in the next four years, that’s a pretty aggressive target,” Mathissen said. “But given the market we’re in, we think that should be possible.”

Originally from the Netherlands, Mathissen moved to the U.S. in the 1990s. In 2007, he sold a company he owned in Connecticut. Looking around for his next venture, he identified energy efficiency as an area of interest.

“So I started looking for opportunities,” he said.

Nyle was a company founded in Brewer in the 1970s, with a focus on manufacturing equipment to dry lumber. But the recession and crash of the housing market, a primary user of lumber, left it in bad shape, he said.

Mathissen said he saw an opportunity not only to get the lumber business back in place as the economy picked up, but also to add a water heating component.

“We ended up restarting the company,” he said.

In 2010, he won a first round of institutional venture capital funding from the Small Enterprise Growth Fund and moved the company from downtown Brewer to its present quarters, taking about 25,000 square feet — 10,000 square feet more than its downtown spot.

In 2012, the company adapted the heat pump technology to make food dryers. In 2017, it further adapted the food dryers to dry product at lower temperatures suitable for the cannabis industry, and formed a subsidiary called Cann Drying Systems.

Energy-efficient heat pump technology is the common factor among the company’s four markets, he explained.

Nyle has expanded through 2020 into more of the building as other tenants moved out, he said. It began taking over the last of the main production space in December and is still moving in.

“We expect to have that completed around the end of March,” he said.

It’s expected the space will be sufficient to account for growth for the next five years or so, he said.

“But eventually we’ll need more space again,” he added.

In keeping with its mission to focus on energy saving products, the company is in the process of putting up a large solar array on the building’s roof to offset electricity used in the production process.

“Since we now have the building for quite a while with a long-term lease, we decided to put up a solar array that covers almost the entire south side of the roof,” Mathissen explained.

Completion of the 266-kilowatt, 682-panel array, installed by Sundog Solar, is expected by March.

Nyle produces units that range in price from a few thousand dollars to $1 million, he said, and range from small water-heating systems that might be 5-feet wide by-5-feet high, to building-size kilns. Most of the 300 to 400 units built annually are the small ones. A $25,000 small- to medium-size heat pump water heater, for example, might go to a hotel or dormitory. Units of all sizes have shipped globally.

In the last 10 years, the company has shipped thousands of units, a number of them to repeat customers, he said.

0 Comments